For the past two years, a team of scientists and researchers from Berlin Aldershof science and technology park have been developing a novel dual-color volumetric 3D printing method which they say improves upon currently available 3D printing technologies, such as stereolithography.

The development of the new volumetric printing process, named xolography, is being headed up by Dirk Radzinski, founder of Berlin Aldershof startup firm xolo, alongside IRIS Aldershof chemist Stefan Hecht and physicist Martin Regehly. According to the creators, the new process solves three “serious limitations” in traditional resin printing; speed, surface quality, and material properties.

“This is the very beginning of volumetric printing,” said Radzinski. “As with every new technology it will take some time to develop and it will start with niche markets. But given the development speed nowadays and given the limited time we spent to develop this technology with just a few people, I am really looking forward to what the future holds for volumetric printing.”

Volumetric 3D printing

Volumetric 3D printing is regarded as the next step onwards from sequential additive manufacturing methods and involves printing from all spatial directions at the same time to produce whole objects in a matter of seconds. The method has been around for some time, although there have been a number of advances in the technology in recent years.

In 2017, researchers from a collection of US-based universities demonstrated an approach to layer-free volumetric 3D printing, while more recently volumetric 3D printing has been used to build perovskite-based solar panels. Elsewhere, a collaboration between the University Medical Center (UMC) Utrecht and École polytechnique fédérale de Lausanne (EPFL) saw the development of a volumetric 3D bioprinting process to create free-form tissue structures.

How does xolography work?

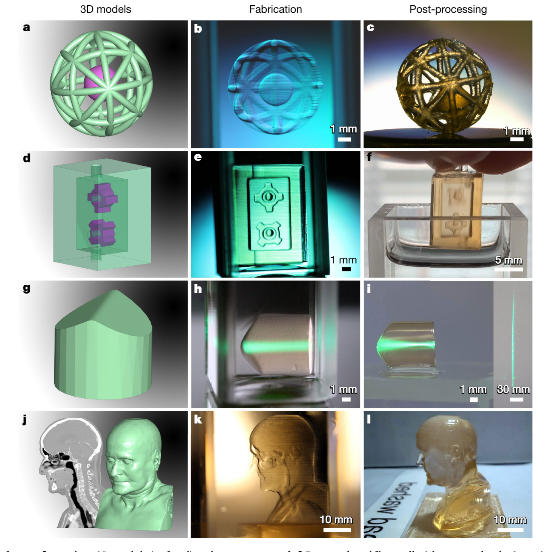

Xolography is a dual-color volumetric 3D printing process which, like in stereolithography, uses light to cure a photoresin. However, while curing occurs along the whole lightpath when light is projected into a vat containing resin during stereolithography, the xolography process requires two different light wavelengths to begin the polymerization process. Wherever blue and red light intersect and meet the two-color photoinitiator in the resin at the same time, curing occurs.

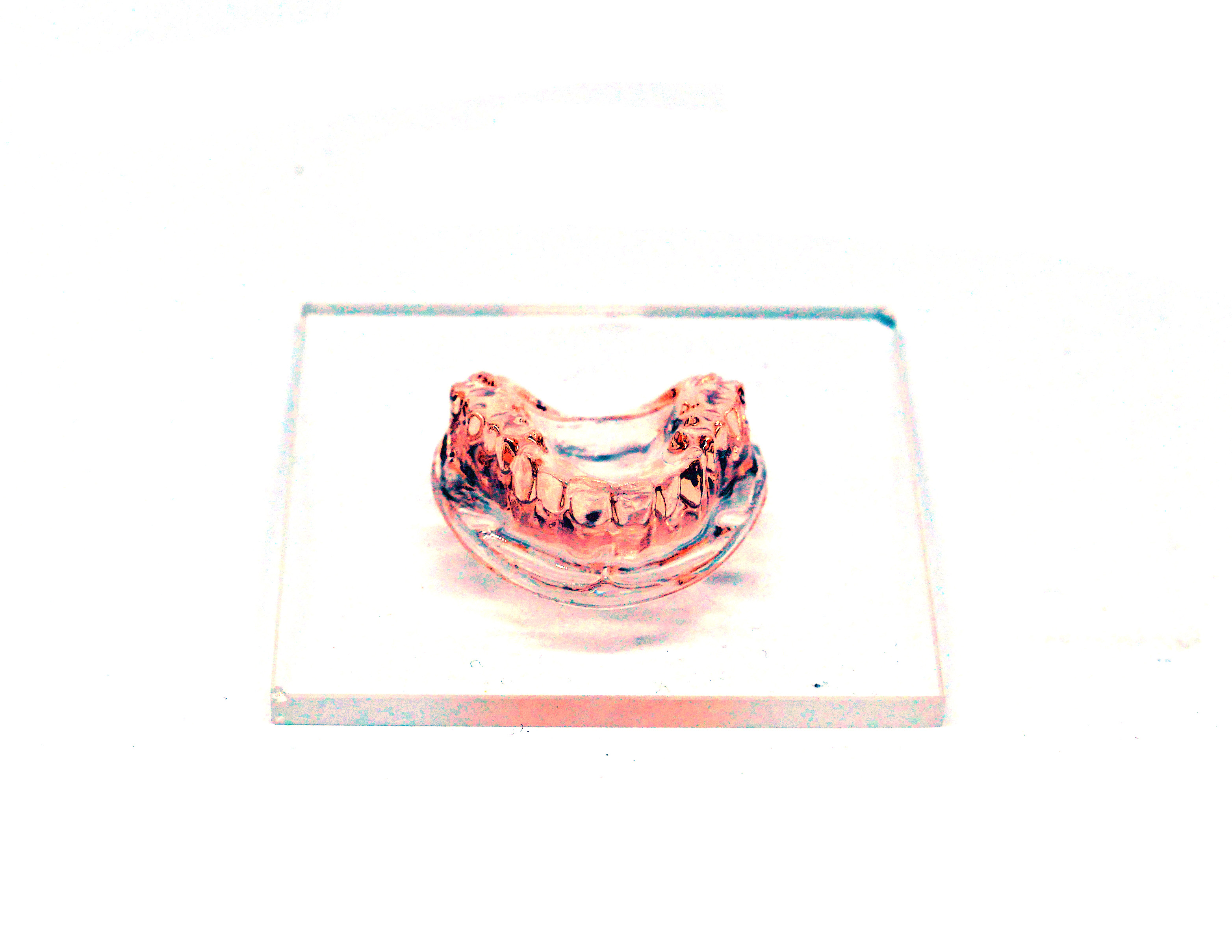

The scientists have so far demonstrated their method by successfully 3D printing a ball, a ballerina, a “thinker” statue, a benchy, and even a dental mold.

Xolography versus conventional 3D printing methods

According to Radzinski, xolography has three main distinctive features that set it apart from other resin 3D printing technologies which utilize light to cure a photopolymer. First of all, the xolography process is significantly faster due to there being no movement of the build plate and polymerization not needing to be finished before the next part can be cured.

Secondly, the surface of parts printed via xolography is exceptionally smooth, owing to the speed of the process while maintaining high printing resolution. The scientists’ paper states that xolography can achieve a resolution 10 times higher than that of all previously known macroscopic volumetric printing processes, with the aim being to print optical grade components without the need for polishing – a feat that is currently not possible with existing technologies.

The third main distinction involves the printing materials used in the xolography process, which Radzinski says have “great potential” to display properties that are desired in manufacturing. Xolography uses highly viscous resins, which isn’t possible with stereolithography as the resin has to flow quickly between the build plate and the printing window. More viscous resins possess longer molecule chains, which enabled the scientists to produce tougher and more durable objects.

“There are also a lot of other advantages,” Radzinski added. “For example, you can print objects in objects up to whole machines if you can freely address voxels in a volume. With a normal resin printer, you need a support structure to hold your object in place. In volumetric printing, the resin supports the object.”

Potential applications

Xolography is well-suited to printing small-scale objects up to around 10cm in size, with Radzinski eyeing up the model sizes within the dental or hearing aid markets as potentially “perfect” applications for the method. The optical market with free form lenses, light conductors, and particularly optic designs that cannot be produced through injection molding, are also areas of interest to the scientists.

Currently, xolography applications are rare across the aerospace and automotive markets, as it does not make sense to print very large objects in a volume of resin, Radzinski says, although there is the occasional use case for smaller sized objects in the automotive sector. The versatility of the xolography method means the scientists can print both hard and soft objects, which could have significant implications for the future manufacturing of optical, fluidic, and biomedical devices.

“On the other end of the materials spectrum is printing hydrogels,” Radzinski offered. “This technology has great promises to bioprint scaffolds in tissue engineering and potentially printing organs in the more distant future.”

Further details on the xolography method can be found in the paper titled “Xolography for linear volumetric 3D printing”, published in the Nature journal. The paper is co-authored by M. Regehly, Y. Garmshausen, M. Reuter, N. König, E. Israel, D. Kelly, C. Chou, K. Koch, B. Asfari, and S. Hecht.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a ball 3D printed via xolography by the Aldershof scientists. Image via Dirk Radzinski/xolo.