Aerojet Rocketdyne is no stranger to 3D printing. Nor are they strangers to rocket engines. Nor are they strangers to 3D printing parts for rocket engines and then proving that they can stand up to burning hot flames. The defense manufacturer has steadily been validating their 3D printed rocket engine parts for actual use in rockets. Their latest hot-fire test has demonstrated that a core main injector, 3D printed for use in their RL10 development engine, is suited for use in large rocket engines.

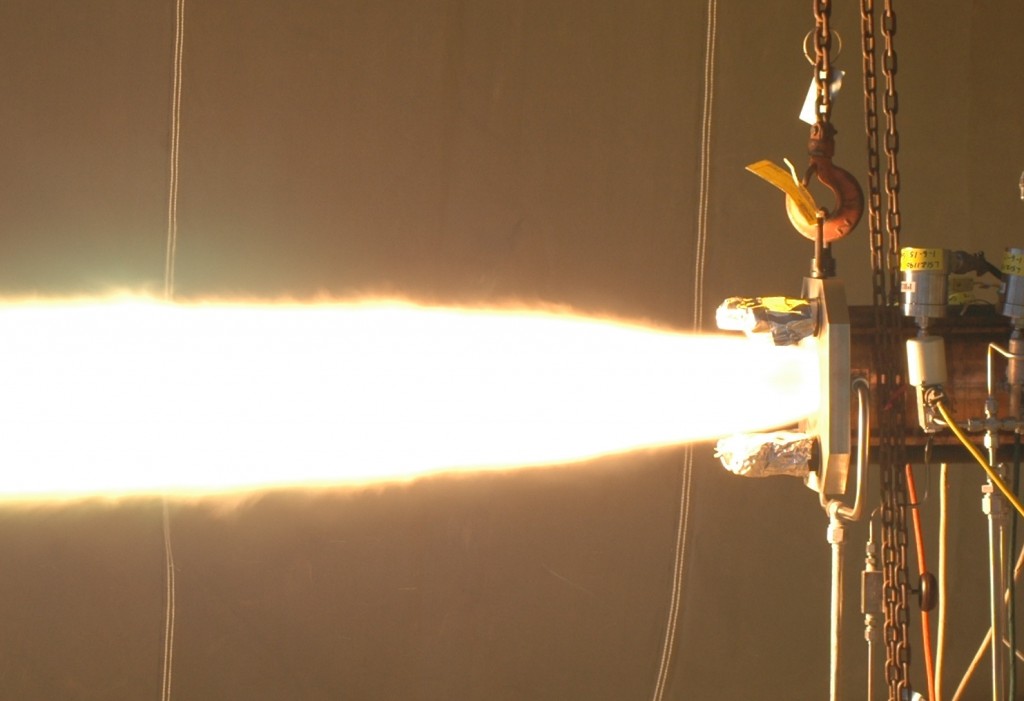

The core main injector was 3D printed using Selective Laser Melting (SLM) technology, allowing the defense manufacturer to 3D print a detailed and complex part capable of withstanding the intense environment of a rocket engine. The part is the result of a $6 million contract with the U.S. Air Force, secured earlier this month, for the 3D printing of parts to be used in liquid-fueled engines. The deal is meant to help the USAF replace Russian-made RD-180 engines for the United Launch Alliance’s Atlas V launch vehicle. During a hot-fire test performed with the USAF and NASA’s Glenn Research Center as part of the RL10 Additive Manufacturing Study (RAMS) program, the team validated the injector’s use in the actual RD-180 engine.

Jay Littles, director of advanced launch programs at Aerojet Rocketdyne, said of the accomplishment, “This is among the most complex components we have tested in a large rocket engine to date. However, we’ve just scratched the surface of what this technology will do to revolutionize our industry. Our design engineers are just starting to take advantage of the expanded possibilities enabled by this new manufacturing technology. They are now free to design products that were once thought impossible to build due to the constraints of traditional manufacturing.”

Aerojet Rocketdyne CEO and president Eileen Drake commented, “Updating our products to take advantage of the advancements we’ve made in additive manufacturing technology is a key part of our strategy to deliver more affordable products to our customers while at the same time maintains the reliability they’ve come to expect. This successful series of tests validates the rigorous approach we’ve been taking and confirms we are on the right path. Incorporating this technology will enable us to reduce significantly production lead times and make our products more cost competitive.”

There are likely more tests where this came from, as the defense company researches the use of 3D printing for engine parts further. In so doing, Aerojet Rocketdyne proves that, if 3D printing is good enough for launching a rocket into space, it’s good enough for just about anything.