Combining industrial 3D printing with traditional manufacturing methods is one probable scenario for how the industrialization of additive manufacturing will take place. A research initiative spanning multiple European countries has undertaken government-funded work to develop a range of tools, strategies, services, and post-processing methods under the banner Advanced Processing of Additively Manufactured Parts or Ad-Proc-Add.

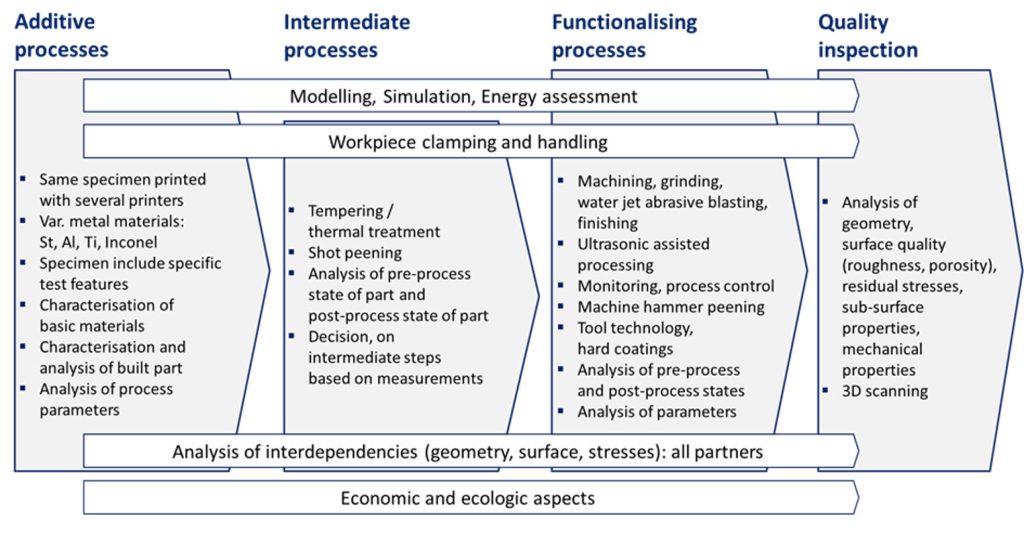

The researchers investigated additive-subtractive manufacturing (ASM) process chains, analyzing the effects of various parameters, strategies, and constraints on the material and workpiece characteristics of additively manufactured components. The research consortium is now disseminating its work to the general public.

The project involved nine research institutions from Germany, Austria, Belgium, and Switzerland and was supported by a user committee comprised of SMEs from all relevant market sectors; aimed to optimize workpiece properties, including geometry, surface, and subsurface characteristics, throughout the entire ASM process chain.

Led by the Forschungskuratorium Maschinenbau e.V. (FKM) with the University of Stuttgart’s Institute for Machine Tools (IfW) overseeing the technical dimension of the project. The establishment of an international research consortium has brought essential expertise in additive manufacturing, fabrication processes, process monitoring and control, equipment and systems, simulation and optimization, and energy efficiency analysis. Extensive experimental studies were conducted using interdisciplinary knowledge to explore the connection between settings of parameters and their impact on outcomes and on the properties of the workpiece during additive and subtractive processes. These studies provided helpful knowledge into tangible consequences as well as techniques for monitoring processes and quality control via correlation analysis.

On the basis of these findings, researchers developed new tool concepts, strategies for metal additive components, advanced post-processing methods, system prototypes for monitoring devices, and additional services, all compiled into a digital compendium.

Benjamin Losert, ecoplus project manager of the Mechatronics-Cluster, explains, “Due to the exceptional collaboration with our industrial partners and under the excellent guidance of FKM and IfW, we not only achieved the ambitious goals of the research project, but also produced industrially relevant and applicable results.”

The acquired knowledge aids system and service providers in the development of new products with enhanced functionalities and enables end-users to implement ASM process chains with increased productivity and enhanced economic and ecological efficiency.

The digital compilation can be downloaded for free from the Ad-Proc-Add website.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an overview of the project procedure. Image via Add Proc Add.