4D printing? Is such a thing even possible? According to ARC Center of Excellence for Electromaterials Science (ACES) and the University of Wollongong (UOW), it is…kind of. They claim that they are working on a way to produce materials via additive manufacturing that shape shift over time with the influence of external stimuli, such as heat or water. Thus, time is added to length, height, and width creating a product that utilizes four dimensions.

So, are we actually looking forward to a 4D printer, or innovative materials that morph into new structures after they are printed via a 3D printer? It seems like the latter. ACES professor Marc Panhuis explains the addition of another dimension to the 3D printing process, “So, as in 3D printing, a structure is built up layer by layer into the desired shape, but these new materials are able to transform themselves from one shape into another, much like a child’s Transformer toy.”

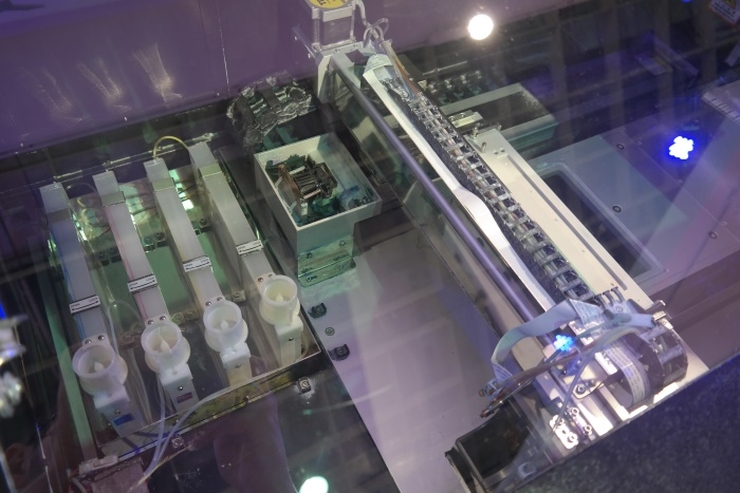

Panhuis and his team are excited about the possibilities this leap in 3D printed materials presents, particularly in the construction, robotics, automation, and medical fields. Currently, ACES researchers are focusing on the medical field and are combining soft robotics and 3D printing technology to build a valve that actuates in response to its surrounding water temperature. ACES researchers claim that they their researchers are the first to combine materials to 3D print a 4D object. Panhuis continues, “The cool thing about it is it’s a working functioning device that you just pick up from the printer. There’s no other assembly required. It’s an autonomous valve, there’s no input necessary other than water; it closes itself when it detects hot water.”

So, whether or not you think this “4D printing” thing has legs, its interesting to keep lengths of time in mind when you are engineering new material processes.