Zurich 3D printer manufacturer 9T Labs, has announced that it has received ISO 9001 certification, a global quality management standard of the International Organization for Standardization (ISO), based in Geneva, Switzerland.

This accomplishment demonstrates 9T Labs’ ongoing dedication to quality at all levels of the organization, says the company. ISO 9001 is a standard that ensures end-user customers receive consistent, high-quality goods and services. According to the company, after several months and dedicated involvement from all levels of the organization, it has joined over one million businesses worldwide in over 170 countries with this crucial certification.

“Implementing ISO 9001 is about reforming corporate culture, ideologies, and a genuine commitment to improvement, both individually and as a company,” said Martin Eichenhofer, chief executive officer and co-founder, of 9T Labs. “Customer happiness is at the center of everything we do, and this ISO 9001 certification ensures that we continue to strive for the highest quality, reliability, and durability in our manufacturing and management system processes today and in the future.”

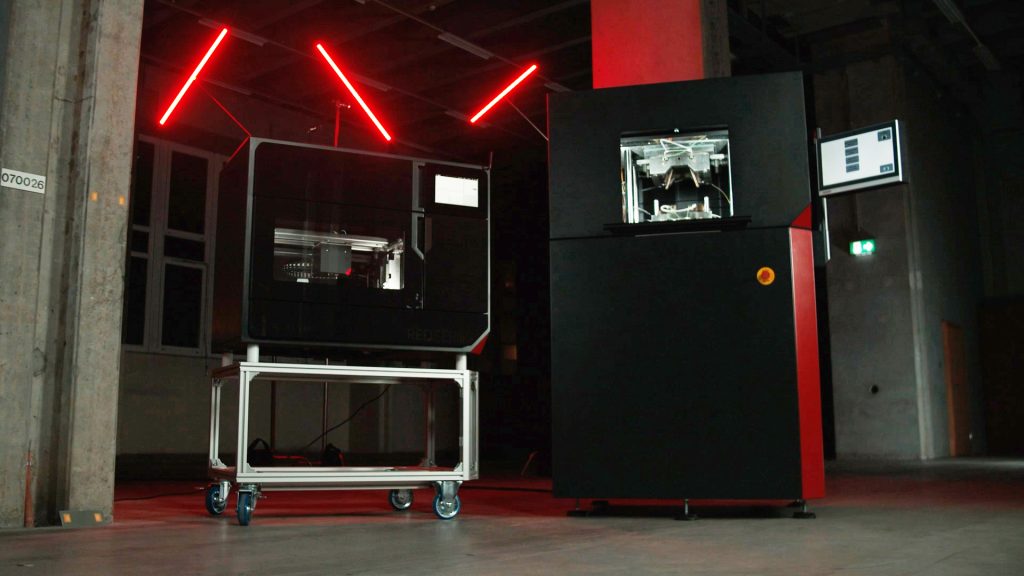

9T Labs’ industrial portfolio

9T Labs AG announced a collaboration with Purdue University to examine and test the feasibility of manufacturing structural aerospace composite applications at scale using Additive Fusion Technology (AFT). The hybrid technology, which automates manufacturing by combining rapid bulk molding compound (BMC) overmolding with high-resolution additive manufacturing, offers a cost-competitive alternative to conventional aluminum aerospace part production. This collaboration with Purdue University, one of the top engineering universities in West Lafayette, Indiana, is a first-of-its-kind venture for 9T Labs.

Furthermore, 9T Labs raised $17 million in Series A funding in February 2022 which it planned to use to commercialize its Red Series Additive Fusion Solution platform. The platform, which combines 3D printing and compression molding, is intended for the manufacturing of advanced carbon fiber-reinforced thermoplastic composite parts in quantities ranging from 100 to over 100,000 parts per year. 9T Labs aimed to fully commercialize the platform by producing parts for end-use applications in the aerospace, automotive, medical, industrial, and consumer goods industries, with the support of industrial 3D printer manufacturer Stratasys and several other key investors.

According to a Composites World report, 9T Labs was previously preparing for an impending expansion into new markets. Following a surge in interest in its Red Series systems, the company sought to capitalize by making a slew of new hires and announcing plans to establish its first US offices. The news of 9T Labs’ increase in demand arrived after it secured $17 million in funding in February 2022, and it’s said to be targeting use cases that require the manufacturing of over 100,000 parts per year using its technology.

“We are proud of our commitment to putting quality at the heart of 9T Labs,” said Josua Woerlen, project manager for the implementation of the Quality Management System, 9T Labs. “The buy-in across the company on this process over the last eight months was truly inspiring to watch unfold.”

Companies that secured ISO 9001 certification

Previously, Maryland-based on-demand manufacturing platform Xometry, announced that two of its Quality Management Systems (QMS) received ISO 9001:2015 and AS9100D certification. In 2019, Xometry was reportedly one of the largest on-demand manufacturing services, with over 2,500 manufacturing partners across the United States. Customers of Xometry can select from a variety of industrial machines from Stratasys, EOS, Concept Laser, and Renishaw, among others, for their 3D printing needs. Xometry also provides CNC machining, urethane casting, and injection moulding.

Furthermore, North Carolina-based hybrid manufacturing start-up Keselowski Advanced Manufacturing (KAM), received ISO 9001:2015 and AS9100D quality certifications for its additive manufacturing and CNC technologies. In less than six months, the company received these certifications and sought to expand from the aerospace and defence sectors into the automotive and transportation industries. KAM’s 70,000-square-foot facility is equipped with two GE Additive Concept Laser M2 Multilaser 3D printers, along with powder analysis tools and post-processing equipment. KAM had 30 employees when it first started and has since expanded its leadership team.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows the 9T Labs team. Image via 9T Labs.