Keselowski Advanced Manufacturing (KAM), a hybrid manufacturing start-up based in North Carolina, has received ISO 9001:2015 and AS9100D quality certifications for its additive manufacturing and CNC technologies.

The company received these certifications in under six months and now aims to expand from aerospace and defence sectors into the automotive and transportation industries. Brad Keselowsk, founder and CEO of KAM, stated:

“When we started the business, we knew one day we would need to have these essential certifications under our belt to do the level of work envisioned with KAM. I am so proud of the entire KAM team for getting this accomplished in such a short amount of time. It’s truly impressive.”

Advancing hybrid technologies

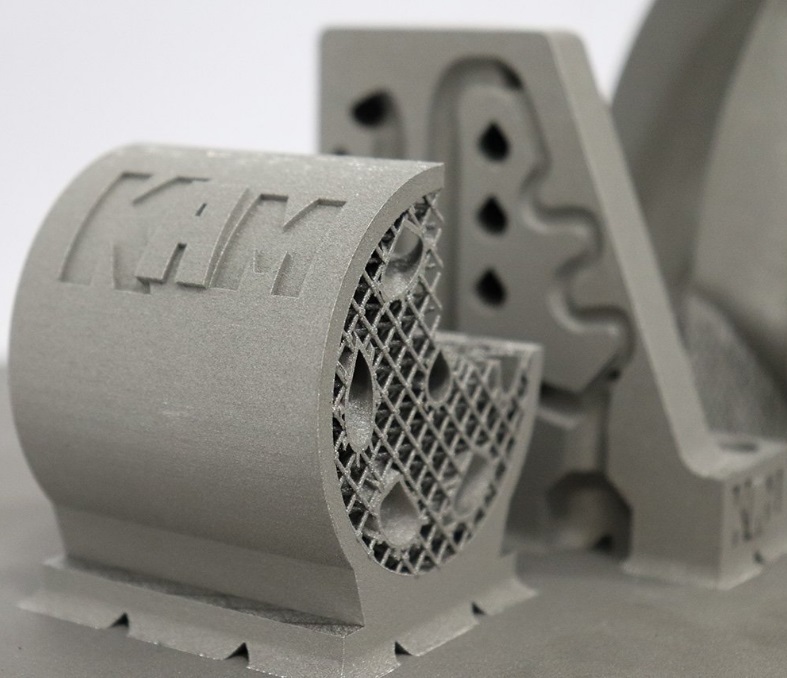

Earlier this year, Keselowski, a professional racing driver and NASCAR champion, established KAM to focus on manufacturing products with high capabilities in light-weighting, thermal, fluid passageways, strength, and conductivity.

The company’s 70,000 square-foot facility is equipped with two Concept Laser M2 Multilaser 3D printers from GE Additive as well as powder analysis tools and post-processing equipment. Upon its commencement, KAM comprised of 30 employees and has since strengthened its leadership team.

The ISO 9001 international standard demonstrates KAM’s ability to consistently provide products and services that meet customer and regulatory requirements. Moreover, the AS9100D certification is based on a standard published by the Society of Automotive Engineers (SAE) titled “Quality Management Systems – Requirements for Aviation, Space and Defense Organizations”.

Investments in subtractive and additive manufacturing

As well as its ISO 9001:2015 and AS9100D certifications, KAM has also expanded its investments in machines and equipment. This included a Mazak i800 VARIAXIS, a 5-axis machining center, a Mazak Quick Turn 350MSY CNC lathe, Starrett optical comparator, a Vacuum furnace, and 4 additional EOS 3D printers.

Jim Thompson, KAM director of operations, said, “These additional investments we have coming down the pipeline really hammer home the power and flexibility of our vertical business model.”

“Combined with our in-house metallurgical laboratory, metrology, digital radiography, and hybrid manufacturing capabilities, we have a wide spectrum of resources available to service our customers’ needs.”

For all of the latest additive manufacturing news and updates, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Visit our 3D Printing Jobs board to find new opportunities in the 3D printing industry.

Featured image shows metal 3D printed components from KAM. Photo via KAM.