Swiss carbon fiber 3D printing specialist 9T Labs is preparing for an imminent expansion into new markets according to a Composites World report.

Having seen a drastic rise in interest in its Red Series systems, the company has sought to take advantage by making a spate of new hires, as well as plans to open its first offices in the US. News of 9T Labs’ boom in demand comes after it secured $17 million in funding earlier this year, and it’s now said to be targeting use cases with its technology that require the production of over 100,000 parts per year.

“We have new systems out in the field being used to produce both developmental and commercial parts,” Giovanni Cavolina, Co-founder of 9T Labs told Composites World. “And now, with many new production applications initiated last year, we have an additional pool of customers who will scale to series production using multiple 9T Red Series systems, just as soon as the technology is validated.”

“Despite the challenges that all of industry has faced during the past two years, we are entering 2022 full of optimism.”

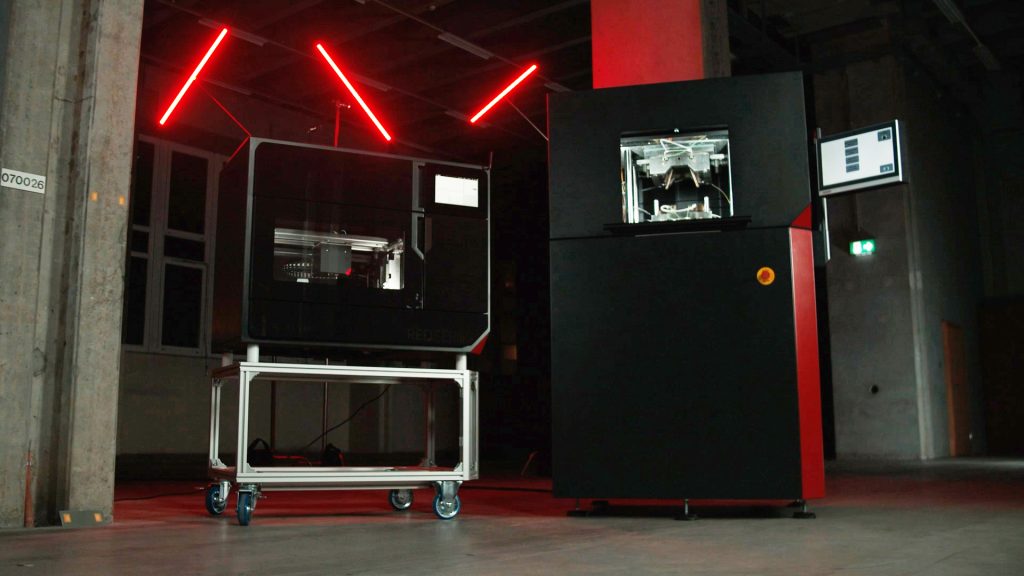

9T Labs’ Red Series machines

Since being spun-off from ETH Zürich in 2018, 9T Labs has been on a mission to make entering mass-production with high-performance composites as accessible as it currently is with metals. In order to do so, the firm has come up with its Red Series Industrial 3D Printing Solution, an end-to-end platform comprising hardware, software and services, designed for producing lightweight composite parts.

Central to the platform’s functionality is 9T Labs’ build module, an extrusion-based fiber layup 3D printer, capable of creating objects reinforced with carbon, glass and basalt continuous fibers. In terms of software, the Red Series also comes with the firm’s proprietary Fibrify program, which enables users to not only model parts, but subject them to FEA simulations in order to validate their designs.

Using the company’s Industrial 3D Printing platform, it’s said to be possible to create both functional prototypes and end-use components, but those seeking to enter serial production, can also opt for its Additive Fusion Solution. Thanks to its extra Fusion module, which packs integrated electric actuation and cooling systems, the machine yields parts with an improved level of layer adhesion and surface finish.

To further the commercialization of its Red Series platforms, 9T Labs managed to raise $4.3 million in seed financing back in 2020, and this was followed by a further $17 million Series A funding round in February 2022. The latter saw the company gain the backing of Stratasys and Solvay Ventures, with former ExOne CEO John Hartner becoming chairman of its board, ahead of its next phase of growth.

Expanding into new verticals

Over the course of 2021, 9T Labs is said to have begun deploying its technologies in a record number of new projects. These initiatives, which are believed to cover everything from aerospace brackets and aviation rib stiffeners to surgical instruments and watch parts, have also been supplemented by the shipment of commercial systems to suppliers, as well as research centers and universities.

One such project has seen the firm’s Red Series system adopted by Setforge, an industrial supplier which aims to develop low-cost 3D printed alternatives to steel, aluminum and titanium parts. While the company’s efforts have initially seen it focus on its core automotive and aerospace clientele, it’s also anticipating being able to dabble in producing luxury goods, sports and medical-related components.

“With all the additional production application projects we’ve got underway, we are very excited to have acquired customers in the sporting goods, luxury goods, and general industrial segments,” added Cavolina. “This helps us support manufacturers in a variety of industries to produce structural fiber-reinforced composite parts much faster, at lower cost, and still meet demanding performance and dimensional requirements.”

In response to this demand, 9T Labs is said to have hired 21 staff, including several sales managers, to lead the marketing of its products in European countries, and as the initiatives involving its systems and the commercialization of its technology begin to come to fruition, it anticipates expanding into further new markets, hence it’s still said to be hiring.

Once it has fully-commercialized its Red Series systems, 9T Labs is set to face stiff competition from a number of others operating in the composite 3D printing space. Israeli 3D printer manufacturer Massivit 3D, for instance, launched the Massivit 1000 late last year. Powered by Cast-In-Motion (CIM) technology, the system is designed specifically to allow for the production of large-format composite molds at pace.

On the funding front, composite 3D printing firm AREVO also raised $25 million in August 2021, in a move that was said to position it for growth moving forwards. The funding round followed the completion of its continuous carbon fiber composite additive manufacturing facility, a complex packed with 70 of the firm’s shipping container-sized Aqua 2 systems, primed for the production of consumer goods.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 9T Labs’ Red Series build module and fusion module. Image via 9T Labs.