Swiss carbon fiber 3D printing specialist 9T Labs has announced the closure of a $4.3 million seed financing round.

Using the funding, the company will focus on further developing its carbon fiber 3D printing technology, as well as scaling its mass manufacturing use cases.

The seed round included contributions from existing investors Wingman Ventures, as well as new additions from Investiere and the Technology Fund. Furthermore, 9T Labs is supported by the ESA Business Incubation Centre (ESA BIC) Switzerland program, a program offering support for entrepreneurs to help develop their businesses, with a particular focus on space.

Alongside the new funding, 9T Labs has also revealed new additions to its board of directors. Andreas Wuellner from carbon material manufacturer SGL Carbon, and Bertrand Humel, previously CCO of EOS, join the board. Humel explains that:

“In contrast to plastic and metal 3D printing companies, which compete with the existing and established automated CNC manufacturing solutions, 9T Labs enters a market which has not yet seen standardized automation and software solutions for mass manufacturing, providing a huge market potential.”

All-in-one solution for carbon fiber 3D printing

A spin-off of ETH Zürich, Switzerland, 9T Labs was co-founded by Chester Houwink, Giovanni Cavolina and Martin Eichenhofer in 2018. The company’s mission statement is to make “carbon fiber composite materials as accessible as ordinary metal materials” through 3D printing. 9T Labs aims to achieve this goal by providing an integrated workflow for producing carbon fiber composite parts. Included in this workflow is an all-in-one solution of software, 3D printing technology, and post-processing capabilities.

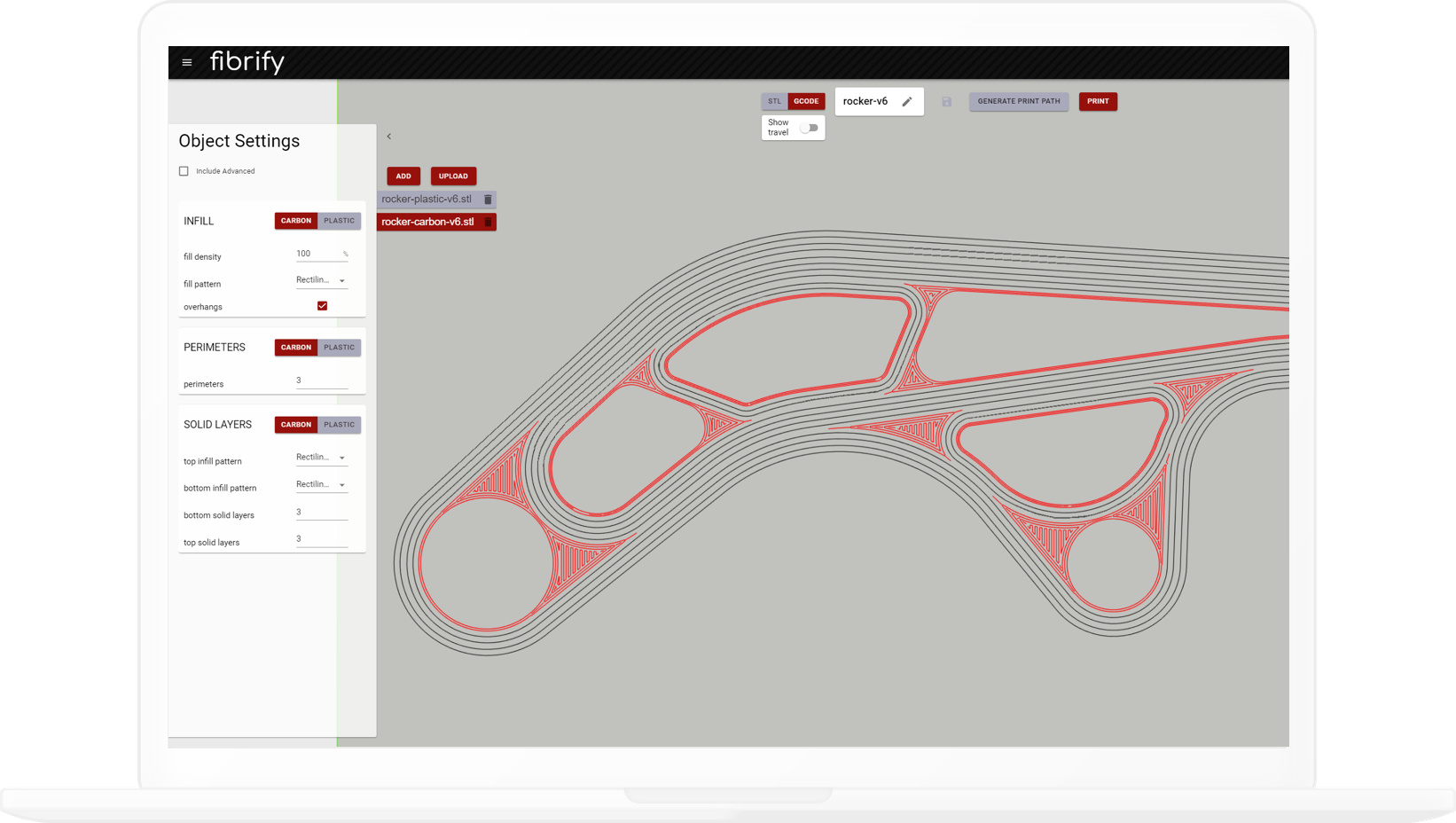

Currently, in development, 9T Labs’ technology includes its Fibrify software, which allows users to monitor their 3D printing activity and optimize fiber placement according to the load case. The company is also developing its 3D printer for carbon fiber composite production, known as the Red Series. It comprises two units: an FDM 3D printer, equipped with a patented printhead for continuous carbon fiber production, and a system for post-processing, named the Fusion Unit. With its 3D printing technology, 9T Labs claims that uses can produce carbon fiber parts with less than two percent void content, and up to sixty percent volumetric carbon composite content.

9T Labs has also developed what is known as the CarbonKit. An add-on for FDM 3D printers, the CarbonKit is made up of a carbon fiber PA12 spool, material box and printhead with dual extrusion, providing existing machines with carbon fiber 3D printing capabilities. Thanks to its technology, 3D Printing Industry listed 9T Labs as one of the 3D printing startups to watch at the MUST 3D Printing event in 2018. In 2019, 9T Labs was also shortlisted for Startup of the Year at the 3D Printing Industry Awards.

Carbon fiber in the 3D printing industry

Carbon fiber composites provide a number of benefits to manufacturers, namely surrounding its mechanical performance. Parts manufactured with the material are able to remain lightweight while providing high strength properties rivaling heavier metal material counterparts. However, carbon fiber’s widespread adoption in the manufacturing industry has been limited by the high costs and long lead times. 9T Labs seeks to capitalize on the capabilities of 3D printing, as it can provide a route for overcoming the hurdles of carbon fiber adoption in the wider manufacturing industry.

Other companies that also provide 3D printers specifically for carbon fiber production include Markforged. The multi-award-winning company provides three large-format 3D printers for composite 3D printing, comprising the X3, X5, and X7 systems, as well as smaller desktop solutions with the Onyx One, Onyx Pro and Mark Two.

3D printer manufacturer Stratasys also provides a carbon fiber FDM 3D printer, known as the Fortus 380mc Carbon Fiber Edition (CFE). It was designed to address the growing demand of carbon-fiber composite applications.

Furthermore, Desktop Metal also entered the polymer 3D printing market recently with the announcement of its Fiber 3D printer, a continuous fiber system powered by automated fiber placement (AFP) technology.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 9T Labs Red Series 3D printer. Photo via 9T Labs.