Neapolitan public transport company Azienda Napoletana Mobilità (ANM) has enlisted the help of Italian 3D printing engineering firm 3DnA to re-engineer mechanical components for Naples’ bus and tram networks.

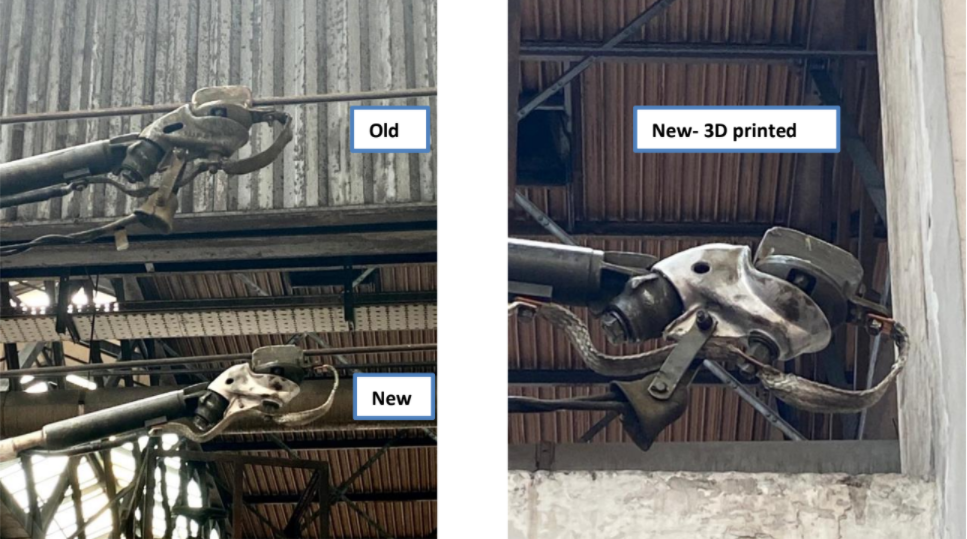

3DnA used reverse engineering to 3D print the ‘trolley heads’ which connect each bus to the network’s aerial power supply lines and mechanically guide rods fixed to the buses’ roofs. There are no longer any spare trolley heads of this kind available on the market, and with traditional manufacturing methods offering a lead time of more than a year, 3D printing was chosen to fill the gap in the supply chain.

Reverse engineering the trolley heads

Due to there being little available data on the original design of the trolley heads, 3DnA resorted to reverse engineer the component using 3D scanning. Once the scan had been obtained, the firm set about reconstructing the trolley heads using 3D modeling software to make them suitable for additive manufacturing.

For the design phase of the process, 3DnA used Materialise’s Magics software. Using Magics, the team was able to optimize the metal printing process in terms of orientation and optimal supports, to ensure success during the printing stage.

3DnA produced the 3D printed trolley head at its recently renovated plant in Pomigliano d’Arco. Here, it utilized two different printing systems to manufacture the metal and plastic parts needed for the trolley heads. For the aluminum components, an SLM500 machine from German 3D printer manufacturer SLM Solutions was chosen. Meanwhile, a Fortus F900 3D printer from fellow 3D printer manufacturer Stratasys was deployed to fabricate the plastic parts, which were made from the firm’s ULTEM 9085 resin, a super-polymer commonly used within the aerospace sector.

Prototypes of the trolley heads were produced, tested, and sent for approval by the Italian Transport Office in the summer of 2020. Currently, two types of trolley heads have been re-engineered and manufactured, with dozens having been already produced for the tram network.

Re-engineering with 3D printing

3D printing is being increasingly turned to for the re-engineering of parts in order to plug supply chain gaps, reduce spare part lead times, and provide manufacturing cost reductions. One recent stand-out example of how this has been successful is during the Covid-19 pandemic, where 3D printing firms stepped in to keep production going in multiple sectors when supply chains failed.

Reverse engineering software and 3D scanning techniques can be deployed to optimize parts for 3D printing, and this has been successfully achieved across multiple sectors for a variety of applications. Within aerospace, additive manufacturing software developer Betatype has aided in the design and re-engineering of metal 3D printed engine shells, a 3D printed aluminum alloy heat exchanger, and an electrical generator housing. Meanwhile, the US Army Aviation and Missile Command (AMCOM) has created a virtual 3D model of a UH-60L Black Hawk helicopter with the hope of re-engineering and 3D printing parts that are no longer in production.

Digital twin technology is also being deployed to speed up the time in which parts can be re-engineered and accelerate the production of 3D printed components. These are digital blueprints of products, components or systems that mirror their physical counterparts, and can be used through CAD/CAM processes to rapidly produce 3D printed parts. Digital twins have been an interesting area of research for the production of manufacturing equipment during unforeseen operational disruptions, and have been previously used to boost productivity in the energy sector and aid in machine process development.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Left: Trolley Head printed with AlSi10Mg. Right: Trolley Head printed with Ultem (Stratasys) & AlSi10Mg. Image via 3DnA.