For the past two years Jason Mosbrucker and Luis Rodriguez Alcalde have collaborated as the 3DigitalCooks. As Luis says the duo are, “passionate and obsessed about 3D food printing.” Last week the 3DigitalCooks hosted several workshops at FabCon 3.D in Erfurt Messe, Germany.

The workshop is one of 40 events during the conference. First held in 2013 and together with parallel event Rapid.Tech, there are approximately 4,000 visitors during the course of 3 days. I asked the 3DigitalCooks about FabCon 3.D and how they are using 3D printing to print food.

Jason told me that the workshop environment enabled 3DigitalCooks to tailor the program to attendee’s interests. He explained, “Also people enjoy seeing the printers working and experiencing the mouth feel of different printing techniques.” He added that 3D food printing is also about, “the visuals and flavor.”

It was a busy week, “It has been challenging to set up the kitchen, prepare the printers and keep the space clean and tight.” The conference was not all work though and the 3DigitalCooks found time to, “mingle with our fellow 3D food printing friends, Bocusini, Message in a Cake, PancakeBot and XYZ printing. And of course Florian Horsch and Thomas.”

The 3DigitalCooks have given presentations on their work in the past, such as this one delivered at Autodesk’s Pier 9 as part of a 4-month residency. But, this is the first time they have run a workshop together.

They are keen to share their passion for the subject and have frequently made their projects available as part of a commitment to the open source community. For example, the design for this cartridge extruder is available here. Anyone can download the plans and use it to print the 3D food printing recipes also available online. The recipes include “Lucky Hummus” and “Digital Pancakes”.

The open source ethos has been a strong influence on the project. Jason explains this is due in part to early experiences with 3D printing. He remembers been introduced by a friend to the technology and thinking of possibilities. But it was not until an unusual challenge came about that he really began to think.

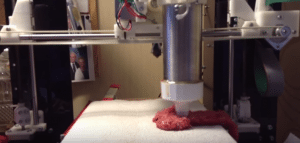

As a self-confessed, “full blown BBQ aficionado” and vocal advocate of his home-nations haute cuisine Jason found that combining 3D printing and hamburgers was an irresistible temptation. With this the BotBQ project was born. Jason soon became immersed in the RepRap forums where he found a community keen to help each other with answers to technical issues. As an early testing video shows there were a number of such issues.

After grappling with hamburger tentacles and meat explosions Jason managed to merge, “two of the best things in the history of history: Barbecue and 3D Printing.” The BotBQ was unveiled officially at the Open Source 3D Drucker Convention in Frankfurt, Germany. For readers who want to enjoy the experience in their own kitchens the instructions are here.

Luis came to the project after working on Natural Machines Foodini. While still living in Barcelona he launched the 3DigitalCooks website in 2013. Since then he has built a number of delta printers specifically designed for 3D food printing and other projects include the development of a peristaltic extruder called the PLYUMP.

Of early experiments with the tools Luis says, “I’m not sure if it’s the first 3D printed peanut butter open hardware logo in the world. But I bet it is in my neighborhood!”

The past couple of years have been spent strengthening links with the emerging 3D food printing community through their informative and entertaining podcasts and videos. In this time, the 3DigitalCooks have visited many of the companies and individuals involved with 3D food printing. This includes meeting Chocosketch in South Korea and an epic 1,000 mile 24 hour stateside road trip to meet 3D food printing pioneers.

3D food printing’s emergence into the mainstream is apparent with a number of companies engaged in what Luis calls, “the chocolate race.” Chocolate seems to be an appealing material to work with. It is easily available, can be melted then resets at room temperature and does not require additional cooking to serve. As Jason cautions, chocolate is actually rather beguiling. He refers to it as “the drama queen” of ingredients.

Chocolate’s complexities as an ingredient stem, in part, from the tempering process. Tempering gives chocolate the taste profile and other characteristics, such as shine and a firm snap, we associate with the eating experience. These characteristics are due to the controlled crystallization of cocoa butter. If conditions such as temperature are not within a narrow range then the chocolate will be unappealing. Keeping chocolate in a molten, workable state and then producing a palatable product is actually much harder than it first appears.

The 3DigitalCooks are also regular attendees at other 3D printing conferences such as the annual 3D Food Printing Conference in the Netherlands. It was at this conference in 2015 that they first met in person. The conference brings together many of the leading academics and industry practitioners under one roof. Highlights this year included 3DChef Julian Sing’s intricate confectionary sculptures and Byflow’s multi-course 3D printed meal.

The workshops at FabCon 3.D covered topics including design, materials and safety. Working with novel or alternative ingredients such insects was also explored. For many attendees the highlight was tasting the results of 3D food printing with regular ingredients rather than bugs.

“We show the recipes while focusing on the food and existing printing techniques” said Jason. The 3DigitalCooks want people to, “understand it in a way they can still see business opportunities.”

The duo even provides suggestions of what to drink with their recipes. For the Lucky Hummus recipe, “try a Rosé, Moscato or Pinot Noir.” Even this aspect of the work required, “serious, and not so serious, testing.” For those that prefer beer Jason has the following advice, “we concluded light-fruity hefeweizen most witbier (white beers)” pair well. “The witbier will add a bit of bitterness but the result will be similar.”

If you are still looking for a reason to start 3D printing food, I’ll leave you with a comment from Luis, “printing food smells much, much better than ABS.”