Scientists at the University of Houston have successfully developed a method for printing crystalline structures with 3D printing, original CIF files, and free software that runs on standard operating systems. It has become common practice at research facilities with modern technological means to use 3D imaging for crystallographers. The imaging allows scientists to perceive the structure in 3D and can be twisted around, yet nothing on the screen can compare to the ability to manually manipulate the structure in person. Researcher Ognjen Miljanić and his coworkers have developed a step-by-step process to take CIF files and convert them into 3D printed objects.

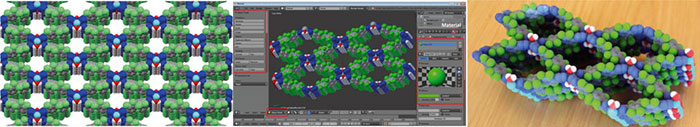

The process is not revolutionary, but it has been streamlined by the team at the Univeristy of Houston for broader use and application. Typically, the method from CIF files, the typical format for crystallographic file storage, to 3D printing required following an abstruse path essentially limiting the ability for proliferation of 3D printed crystallography. With a simple formula from CIF to Mercury (software familiar to crystallographers) to Blender (a 3D graphics product commonly used for animated films) to finally a 3D printer. While acknowledging other similar methods exist, Miljanić insists the streamlined method now offered provides greater flexibility for printing particular structures such as segments of “infinity” structures.

Support has surfaced internationally for Miljanić’s method. Simon Leigh, a 3D printing expert at the University of Warwick says: “It’s providing researchers with a brilliant opportunity to get right in amongst the structures and see what’s going on rather than just looking at them on a computer screen.” And James Bannock, a researcher at the Centre for Plastic Electronics at Imperial College London continues the support: “The application here is potentially most interesting for teaching or outreach activities where high quality, vibrant models can be used to convey understanding of complex conformational structures in a fun and engaging way.”

The colours are real thanks to the use of full colour sandstone. The quality of these structures and the ease by which they can be transferred from file to print promises to provide crystallography a research standard with the aid of 3D printing. Miljanić echoes sentiments across the 3D printing world hoping to reach those still in the dark that as the technology improves, the availability increases. There are affordable options that bring these prints within tactile reach with some simple research. Possibilities and certain crystalline structures are infinite.

Source: Chemistry World