Alessandro Usseglio Viretta, Fabnami’s founder and designer, is what you would call a “diversely talented” person. His biography says he is a “Physicist with a PhD in Computational Neuroscience [from ETH Zurich] and several years’ experience in software development and consulting for financial risk management.”

Among other projects, he prototyped particle detectors at CERN, Geneva, researched biological networks, developed a machine-learning based software for time-series prediction, with a focus on automated (algorithmic) trading and has now ventured into what he considers to be the most interesting technological trend in a while — aiming to develop software and services to cater to the new needs of developing or established industries.

During the past few years Alessandro’s focus has been the 3D printing industry. He lives in Switzerland but was in Milan last week, where I had a chance to meet him to find out more about his Fabnami project, which is now starting to attract the attention of 3D print bureaus that seek to employ a comprehensive and easy to use e-commerce solution.

Fabnami wants to be a one-stop software solution for 3D printing service providers to offer their customers browser-based real-time manufacturability checks, immediate print quotes and a full-featured e-shopping experience. Fabnami’s back-office doubles as a 3D-print centric Entereprise Resource Planning application that helps streamline the shops’ daily business. Its core engine is based on proprietary algorithms that process 3D data, locate potential issues and optimize print parameters.

Alessandro designed Fabnami’s architecture and developed most of the software’s back-end. The front-end has been designed as a single-page app to provide a modern and immediate user-experience. With a little training, anyone can deploy Fabnami to offer 3D printing services by using their own machines or leveraging external 3D-print services. The software’s engine can also be accessed via a Web API that programmatically processes large numbers of files without human interaction.

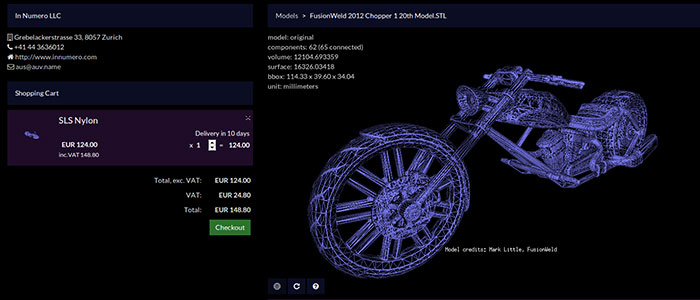

Currently five companies throughout Europe and North-America are implementing Fabnami and one Asian design marketplace is using its web API, says Viretta. I got to try the demo and, in fact, it performed smoothly, allowing me to rapidly find out the price for printing an .stl file. “I worked hard on this software to improve its performance in terms of model analysis accuracy and price calculation speed” – Alessandro explained. “Fabnami is presently the most sophisticated solution on the market and it’s targeted to newly-founded 3D-print bureaus as well as established ones that want to tap new market segments and streamline their processes.”

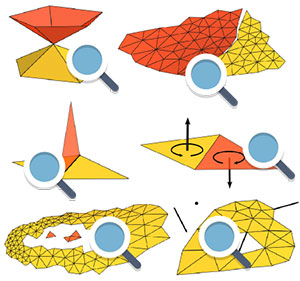

Another of Fabnami’s proprietary algorithms minimizes the support-material volume by quickly finding the best orientation of a 3D model, thus providing more accurate online print price quotes and saving time in the pre-print processing.

For the end-customers the process is just as easy: All they need to do is upload the .stl file and have Fabnami analyze and price it. Within a few milliseconds the model is displayed in Fabnami’s WebGL integrated viewer and a full list of prices for different materials and finishes (and delivery times) appears as a scroll-down list on the browser’s window. Customers just need to select their preference by hitting the familiar “add to cart” button, then proceed to check out and pay by credit card.

Who will use Fabnami? Given the current paradoxical state of most 3D printing services, which are using the world’s most advanced manufacturing technologies in combination with general-purpose software and time-consuming manual processes, it seems that it would be a perfect fit for quite a large number of companies. In fact the software’s name (Fabrication + Tsunami) may prove prophetical: the lack of an easy-to-access, rapid and accurate solution for 3D printing customers and 3D-print providers is probably one of the main factors that is still holding back 3D printing’s mass adoption.

The goal for Alessandro is to make 3D printing uninteresting “because” – he says – “that would be the ultimate sign that it has successfully reached the mass market. 3D printing will become yet another technology that changed our lives. To get to that point, we need to make the complexity of this technology disappear and Fabnami wants to be the missing button to make it happen.”