This week’s edition of Sliced, the 3D Printing Industry news digest, features a 3D printed celebration of the first moon landing, virtual clothes shopping, and the launch of an AM Network Map.

This roundup also includes stories from Knust-Godwin, Torus Group, SPIE, Open Bionics, Geomiq, Onshape, Wikifactory, ETH Zurich, 3DEO, AlphaSTAR, PyroGenesis, Hermeus and more.

Achieving precision with 3D printing

For oil and gas industry, Knust-Godwin, an American precision machining company, has acquired four RenAM 500Q quad laser metal additive manufacturing machines from global engineering technologies company Renishaw. Knust-Godwin is using these high-productivity AM systems for serial production of oilfield instrumentation. “A project which previously required a 24 month wait from concept to commercialization can now be reduced to eight months,” explained Mike Corliss, VP of Technology at Knust-Godwin. Other than the drastically shortened lead times, the company is also benefiting from reduced waste and post processing steps.

Dutch maritime manufacturing company VABO Composites will be using thermoplastic 3D printing to make mold parts for high-end yacht builder Royal Van Lent. A 800 m^2 composite superstructure and mast of a yacht is expected to be built in a year. Glass and carbon fibre, as well as resin infusion processing, are included in the chosen composites.

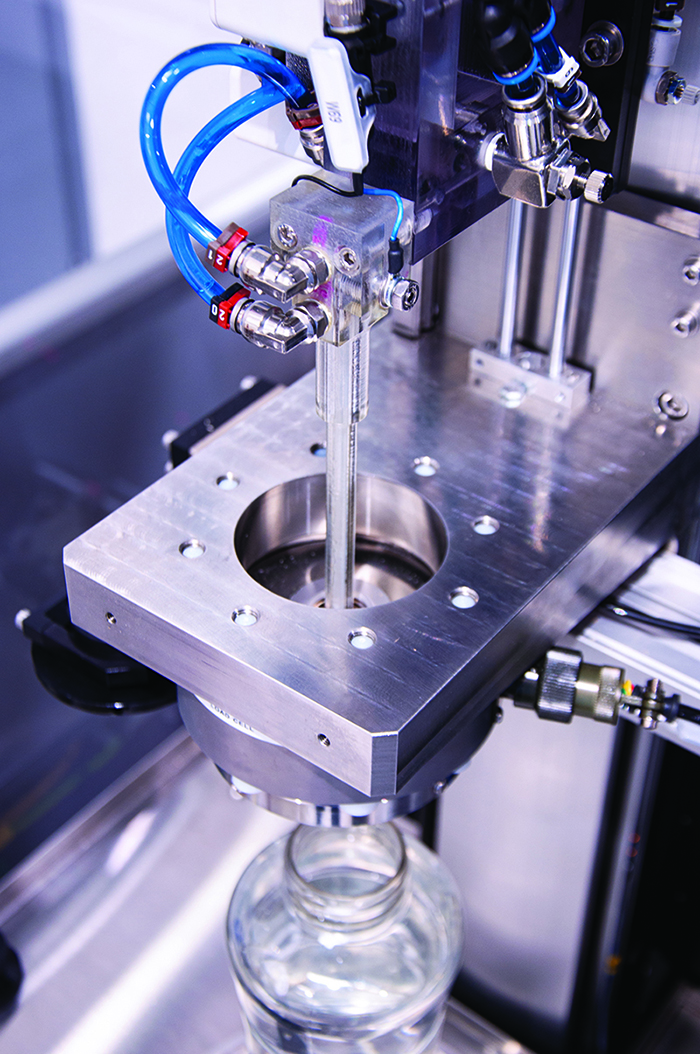

After experiencing problems with reliability and functionality Torus Group, a bespoke metrology solutions specialist, has created a filling assembly on its volume gauge machine using 3D printing. A complex construction of channels, inserts and electrodes forms the assembly, which allows water flow during bottle volume testing. SYS Systems, Stratasys’ UK partner, supplied Torus with Stratasys Objet260 Connex3 for 3D printing the manifold and nozzle in the new assembly. The rigid VeroClear material is used for its excellent detail and dimensional stability. “They’re now 100 times better.” said Chris Freshman, R&D Director of Torus Group. The parts of the new assembly can now be printed in 19 hours to an average accuracy of 50 microns.

At Italian research institution Istituto Italiano di Technologia (IIT), the Centre for Biomolecular Nanotechnologies bought an electronics additive manufacturing system DragonFly Pro from Nano Dimension. The centre’s researchers are creating a new development platform for rapid device and microsystem prototyping. With electronics 3D printing, it is now possible to produce and embed their MEMs technology and wearable electronics into customized multilayer PCBs. Regardless of a circuit’s complexity, circuit boards can now be prototyped in just hours instead of weeks. DragonFly Pro enables rapid innovation and significant time-savings for developers.

Incorporating 3D printing in business strategies

European energy and communications company SPIE has bought industrial automation company Cimlec group from French industrial engineering firm, and Prodways parent company, Groupe Gorgé. Cimlec group specializes in robotic, automation and engineering services and generated €42 million in revenue last year. The financial resources gained from this operation will be used to strengthen SPIE’s control of robotics and 3D printing.

In last month’s International Conference on Materials for Advanced Technologies, Singapore announced its policies to keep its manufacturing industry relevant. Currently, the country produces world-class research in 2D and nano-materials that can be applied in membranes, sensors and microelectronics. On their next steps, Heng Swee Keat, Singapore’s Deputy Prime Minister said “Singapore is applying them [material sciences] in impactful technologies such as solar cells, biological membranes, additive manufacturing and batteries.” In order to seize new opportunities, Heng stressed the building and strengthening of global partnerships.

Mobility goes Additive, an international network of 3D printing companies and research institutes, has recently reached 100+ network members. It also celebrated the launch of its exclusive digital tool AM Network Map. Members can search for potential partners in the network, localizing business companions nearby and promoting their service portfolio. On 16-17 September, the MgA Annual Meeting 2019 in Berlin will address new uses cases and cross-industry insights. Tickets available soon.

Creative replication and fabrication

In the arts, 3D scanning and 3D printing have created high-definition 1:1 replicas of Neil Armstrong’s Apollo 11 spacesuits for public viewing. This suit is part of the Smithsonian’s plan to celebrate the half-century anniversary of the moon landing. The replication process started with capturing a highly detailed 3D scan of the suit in standing form. Then the entire full-suit 3D scan was divided into a number of segments using CAD tools. Each part was later 3D printed using a voxeljet VX1000, which has a massive build volume. Details were much as the cloth stitching, were well-captured by both the scans and subsequent print. After finishing and painting, these life-sized spacesuit models will be displayed in 15 different baseball stadiums across the United States.

Switzerland also demonstrated the potential of computational design and digital fabrication. In collaboration with the Origen Festival in Riom, ETH Zurich has 3D printed the Concrete Choreography installation. Consisting of nine concrete columns with unique complex geometries, the installation frames and informs the dance performances. Through a fully automated layered extrusion process, each 2.7m column can be 3D printed in 2.5 hours without formwork. As materials can be strategically printed at necessary spots only, these hollow structures also demonstrates a more sustainable approach to concrete architecture.

Improving the product development process

Cloud product development platform Onshape released the independent study “The State of Product Development & Hardware Design 2019“. Responding on how to boost productivity and innovation in product development, 850 executives, engineering managers and product designers offered their insights. The study revealed that companies now focus more on improving their design processes than their design tools. The top focus areas for improvement in the product development process are better team communication, visibility and data management.

“It’s surprising to see that improvements to processes are rated as higher priorities than some of the more trendy media topics like additive manufacturing and generative design,” commented Jon Hirschtick, the CEO of Onshape.

For Onshape’s real-time data management, Aerospace startup Hermeus is designing its upcoming Mach 5 business-class hypersonic jet. “Onshape’s built-in versioning just makes things easier,” Glenn Case, Hermeus co-founder and CTO said. “You’re always up to date. You can come in to work in the morning and not wonder who updated what. Having the ability to see our colleagues’ design updates immediately show up on other CAD users’ machines is incredible.” The Hermeus aircraft will have a range of 4,600 miles at a cruising speed of 3,300 miles per hour, reducing the flight time from New York to London from 7.25 hours to 90 minutes.

Collaborative product development platform Wikifactory seeks to improve the documentation process in product design. Its Docubot Challenge invites the global open source community to find a hardware solution to this problem. Documentation is essential for open knowledge of digital fabrication machines, such as 3D printing, hardware, electronics programming and robotics. A real-time documentation assistant should make the process more interactive. Features such as taking photos and videos on command, and speech-to-text conversion are recommended by Wikifactory. If successful, the hardware will accelerate engagement and collaboration, further connecting product developers to 3D printing.

Expanding and rebranding

Open Bionics, a UK manufacturer of 3D printed, bionic limbs for amputees, is expanding its operations. The company has just signed up over 600 clinics in the United States. “It’s a huge moment for Open Bionics,” co-founder Sammy Payne commented. Previously, its 3D printed “Hero Arm” for Tilly Lockey has featured in the movie Alita: Battle Angel.

A London-based on-demand manufacturing company, previously named Manufacturing Source, has recently rebranded as Geomiq. Geomiq is a design and manufacturing workflow tool for over 500 hardware companies worldwide such as GE and BMW. Services such as CNC machining, injection moulding, sheet metal and 3D printing are offered at the site.

Express Group, GoPrint3D‘s parent company, has been identified as one of London Stock Exchange Group’s 1000 Companies to Inspire Britain 2019. The report celebrates the UK’s fastest-growing and most dynamic small and medium sized businesses (SMEs) over 40 sectors. To be awarded, Express Group has to demonstrate positive revenue growth over the last three years and outperform its sector peers.

More than a DIY school project

American physicist Sterling Backus has 3D printed a Lamborghini Aventador with his son. While the supercar costs close to $400,000 new, the dad challenges himself with a $14,000 budget. Learning from YouTube, Backus 3D printed small sections with consumer 3D printers. After gluing them all together, the parts were covered in pre-preg carbon fibre material. To finish, he vacuum-wrapped the parts such that they look like one single panel. Upon finishing the project, the sterling replica will tour around local schools for promoting STEM.

The DIY girls, formed by 12 teenagers from San Fernando High School, invented a solar-powered tent for the homeless. Through sewing, coding and soldering, the team equipped the tent with insulated fabric, solar panels, a safety locking system and a UV sanitization system. The DIY girls also 3D printed a box to house wires for the solar panels. Their product was presented at an MIT conference last month and won a $10,000 development grant from the Lemelson-MIT Program.

3DEO, a Los Angeles-based metal 3D printing service provider has also reached out to young innovators. The company recently hosted the two winning teams of its technology competition Mission: Impact Challenge on a VIP Innovation Tour. The six students visited 3DEO’s factory and R&D room, learning about various 3D printing and post-processing techniques. The company also demonstrated how to it uses plastic 3D printing to make parts for its metal 3D printers.

3D software for designers

Fashion technology company Alvanon and sportswear giant Under Armour new have released 3D avatar size sets for garment designers to virtually develop and fit clothes. Powered by body data research, full spectrum of “real” bodies improves sizing and standardization. 3D virtualization also minimizes physical sampling, time and cost of product design.

American software company AlphaSTAR Corporation has released the latest version of its additive manufacturing simulation suite, GENOA 3DP. Utilising multi-scale progressive failure analysis, GENOA 3DP simulates the AM process from material characterisation to in-service qualification of an AM part. Two new modules for the platform have been introduced: a build path error management tool PathCoverage and a thermal management tool TMg. “The newest modules reflect what is needed by industry to continue moving Additive Manufacturing forward,” commented Dr Rashid Miraj, Director of Technical Operations at AlphaSTAR.

Collaborating with government agencies

PyroGenesis, a Canadian plasma torch specialist and metal powder producer, has completed its special order from a government entity which was closed in July. Using its NexGen™ plasma atomization system, PyroGenesis produced a specialty reactive metal powder with properties similar to titanium for the first time.”Being able to produce this specialty reactive metal powder in such a short period of time underscores the versatility of our new plasma atomization process in producing best-in-class powders,” commented Massimo Dattilo, VP PyroGenesis Additive.

Going beyond earth, nScrypt and Techshot‘s BioFabrication Facility (BFF) Tool has launched abroad with SpaceX’s Falcon 9 on 21 July. This is part of a NASA sponsored mission to 3D print human organs and tissues at the International Space Station.

Subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter for all the latest additive manufacturing news.

Find your next opportunity on 3D Printing Jobs.

Featured image shows Sliced logo over 3D scanning of the Apollo 11 spacesuit. Original photo via the Smithsonian.