Montreal-headquartered plasma torch specialist and metal powder producer PyroGenesis has unveiled the NexGen® Plasma Atomization System. A patent-pending process, PyroGenesis NexGen® is capable of producing metal powder for additive manufacturing at a rate of over 25kg/h.

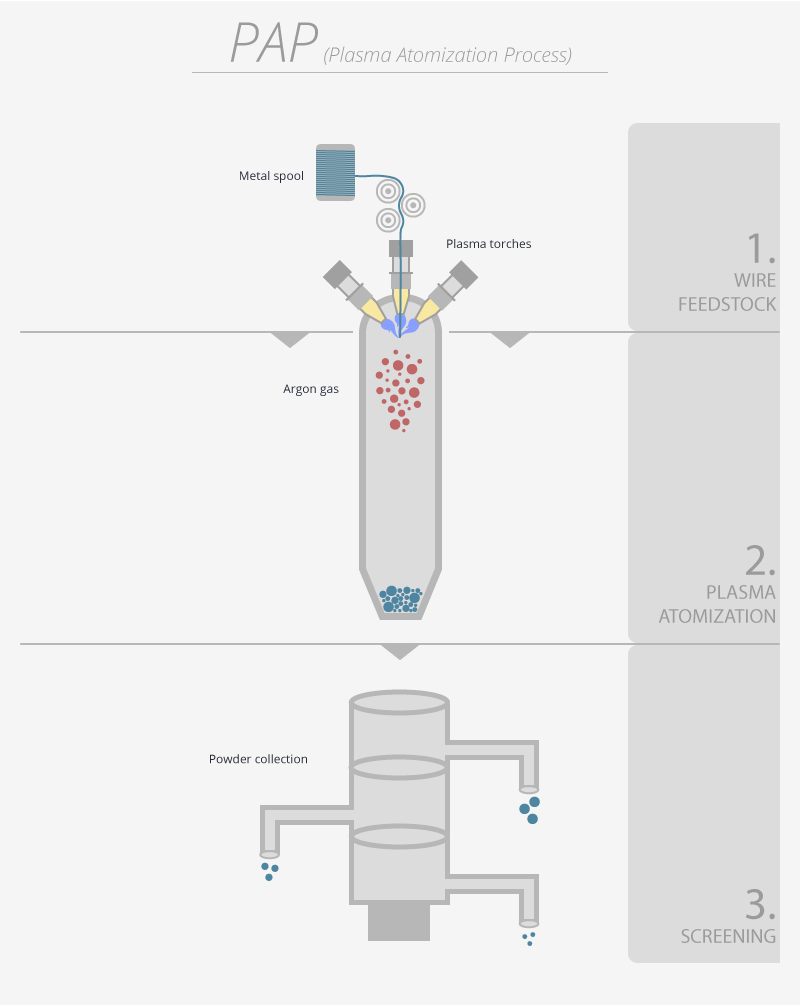

The method is a long-awaited upgrade of the original Plasma Atomization Process (PAP) coined as a term and invented by PyroGenesis in 1995. Intellectual property for NexGen® was filed in 2015, and currently holds a provisional patent. Speaking in relation to the company’s long history with the technology Massimo Dattilo, Vice President of PyroGenesis Additive, comments, “Plasma atomization is considered the gold standard for the production of AM powder.”

“As the inventor of plasma atomization, and being plasma experts, PyroGenesis is dedicated to continuous improvement.”

“Our NexGen® System, which is now proven, to the best of our knowledge, has shattered all published plasma atomization system production rates.”

Plasma competition

Plasma atomization has become a well-known in additive manufacturing as it is capable of producing powders with uniform particle size, an essential feature for successful builds. At present, PyroGenesis is one of just a handful of companies in the world to employ this technique for making AM powders, all of which are based in Canada.

Through the development of NexGen® PAP, PyroGenesis specifically targeted higher production rates and lower wastage. As such, PyroGensis President and CEO P. Peter Pascali says that it allows the company to produce materials at “exceedingly competitive price points,” which will be crucial to its position among the growing competition. It will also unlock titanium alloys for new markets, as Pascali adds, “This would allow high value materials to be accessible to many new markets, which have up until now found these high value materials, such as titanium, to be too costly.”

PyroGenesis’ Industrialization Plan

Currently, PyroGenesis is amidst an industrialization plan for its additive manufacturing powders. Seeking to achieve round-the-clock materials production, the introduction of the NexGen® Plasma Atomization System is an important milestone toward this end.

Already, the NexGen® System has proven its capabilities fulfilling the company’s recent order from an anonymous government entity. Though details of the order remain undisclosed, PyroGenesis has confirmed that the powder produced for this customer was a reactive metal, and the first non-titanium alloy processed by the company.

Pascali concludes, “Once again, PyroGenesis is leading the way with its plasma expertise, and this is just the beginning.”

“We fully expect to improve on all aspects of production, including even improving upon these record shattering production rates.”

Vote for PyroGenesis and more leading industry stakeholders in the 2019 3D Printing Industry Awards.

For more of the latest 3D printer releases and other news subscribe to the free 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

Featured image shows metal alloy powder. Photo via PyroGenesis