In this edition of Sliced 3D printing news, we feature: BigRep, Griffith University, Höganäs, the Russian Institute of Aviation Materials, Manufacturing Technology Centre, and HP.

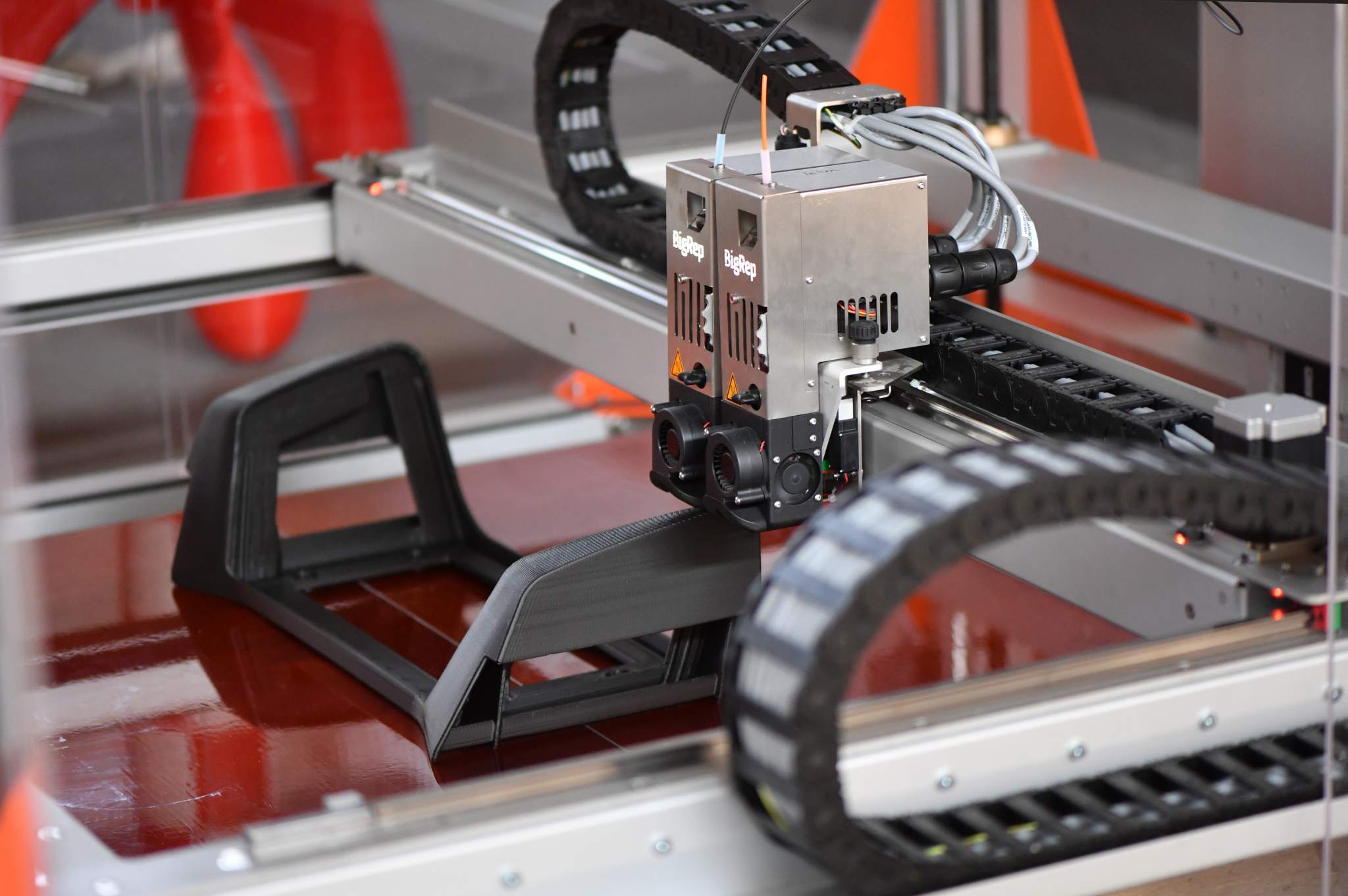

BigRep names Moshe Aknin as CTO

German 3D printing company BigRep has announced ex-Stratasys Senior Director Moshe Aknin as its new Chief Technology Officer (CTO). BigRep is a manufacturer of large-scale 3D printers which have recently been employed by Deutsche Bahn to create train parts.

René Gurka, CEO of BigRep said,

There is only a handful of candidates with his expertise in additive manufacturing worldwide, and it is a great honor that after many years of working at the market leader Stratasys he has chosen BigRep. Moshe will further accelerate our path to become a global leader of industrial solutions in 3D printing.

Gurka recently gave his thoughts on the future of 3D printing in the next five years as part of our thought leadership series.

Australian university plans multi-million medical 3D printing institute

Griffith University in Gold Coast, Australia is planning to construct a medical 3D printing institute. Known as the Advanced Design and Manufacturing Institute, the proposed center is expected to cost millions and is currently awaiting approval from the Australian government.

The facility, which could be built by 2019, is expected to be located between Gold Coast University and Gold Coast Private hospitals. While initially billed as medical center, the institute would also look towards accelerating general manufacturing in the area. A medical 3D printing center was opened last year in Melbourne Australia with a similar purpose and elsewhere in the world, Quebec has pledged $2 million for its own facility.

Höganäs expands Digital Metal into titanium

Sweden-based Höganäs has announced it has expanded the material offerings in its Digital Metal process. The metal 3D printer manufacturer recently announced the delivery of its P2000 to French industrial institute, CETIM.

Now, Höganäs has revealed its proprietary Digital Metal will now include Ti6Al4V. Titanium is a particularly useful material for its low weight and high strength characteristics.

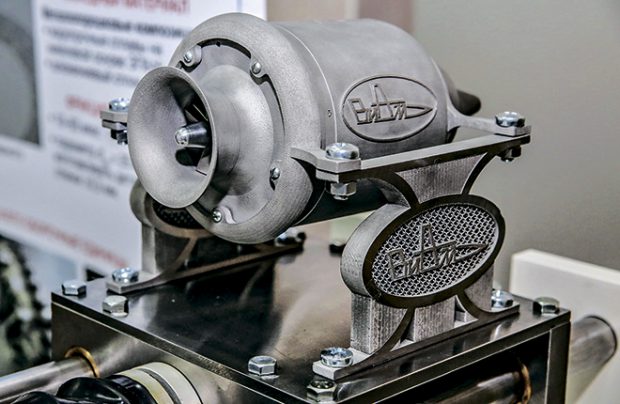

Russia 3D prints UAV engine

Russia Institute of Aviation Materials (VIAM) is presenting a metal 3D printed gas turbine engine for UAV aircraft this week at Russian airshow – MAKS 2017. According to Russian Aviation Insider, the engine was fabricated using VIAM’s own proprietary technology which promises speeds 30 times faster than traditional production methods.

Weighing 900 grams, the prototype UAV engine produces 10 kg of thrust and the institute is now planning to produce larger models capable of 150 kg of thrust. VIAM intends to print and test the engines by the end of 2018.

UK’s Manufacturing Technology Centre begins testing HP’s 3D printer

The British Manufacturing Technology Centre (MTC) will now begin testing HP’s Jet 4200. MTC will be evaluating the machine for the European Space Agency as the centre provides a platform for academia and companies to collaborate in research.

The HP 3D printer will undergo testing at National Centre for Additive Manufacturing at the MTC and was acquired via Europac 3D. John Beckett, Managing Director of Europac 3D explains,

We could think of no better place to install the first machine than at the MTC, as it is at the forefront of manufacturing technology and provides an ideal location for organisations to see the machines and examine how they can be applied to reduce costs or improve production speeds.

3D Printing Industry visited the MTC facility earlier this year which is based in Nottingham.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows the Sliced logo.