Leading market report publisher MartketsandMarkets is reporting that the 3D printing materials sector is going to reach $1.052 billion in global turnover by 2019. The report, which is available for $4,650 as a single user licence and $ 7,150 for a corporate license, splits materials up into categories such as Plastics (photopolymers, ABS, PLA, Nylon and more), Metals (Steel, Silver, Aluminum etc.), Ceramics (Glass, Silica, Quartz and others), as well as other materials such as Wax, Laywood and other compound hybrids, and analyzes the distribution market by global regions and trends.

M&M estimates that the materials market is going to grow at a compound annual growth rate (CAGR) of 20.4%, which means that the firm currently estimates the market’s total value at around $400 million. By 2019, plastics are expected to represent 64% of total value ($671 million), also growing at a similar CAGR (20.3%), which would place its current value at roughly $250 million.

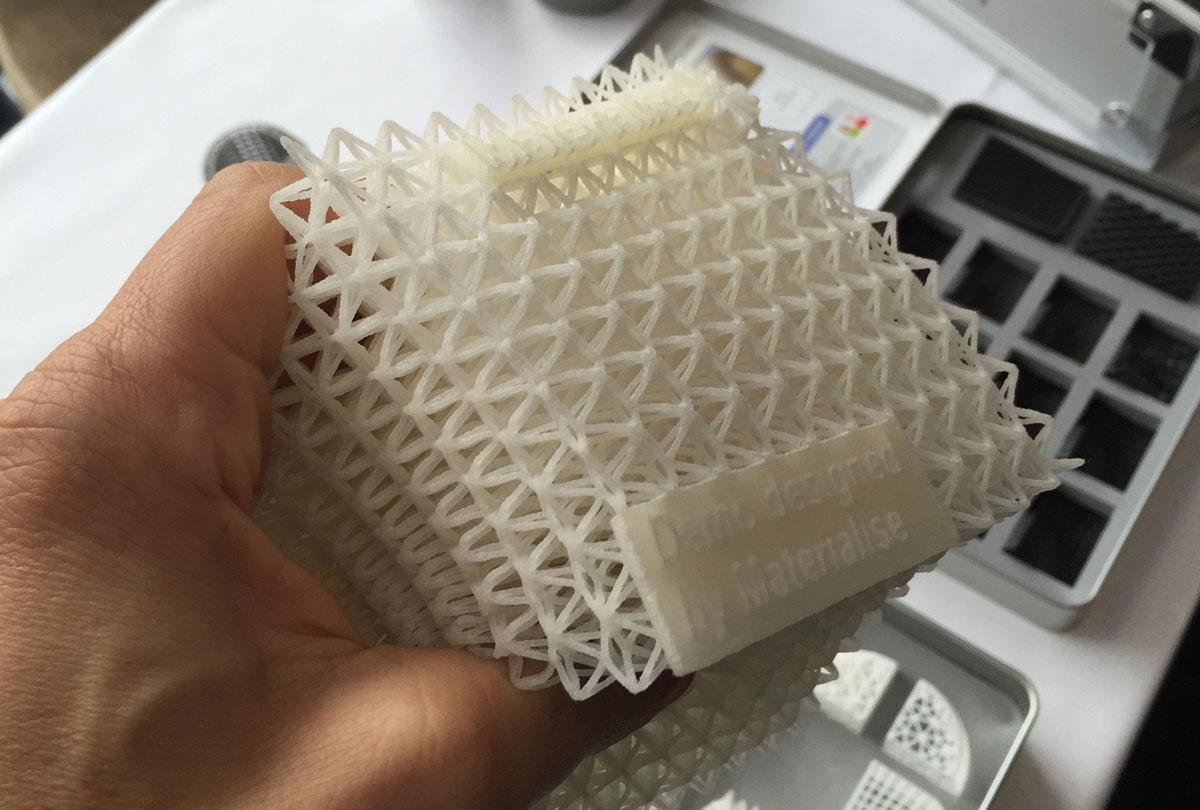

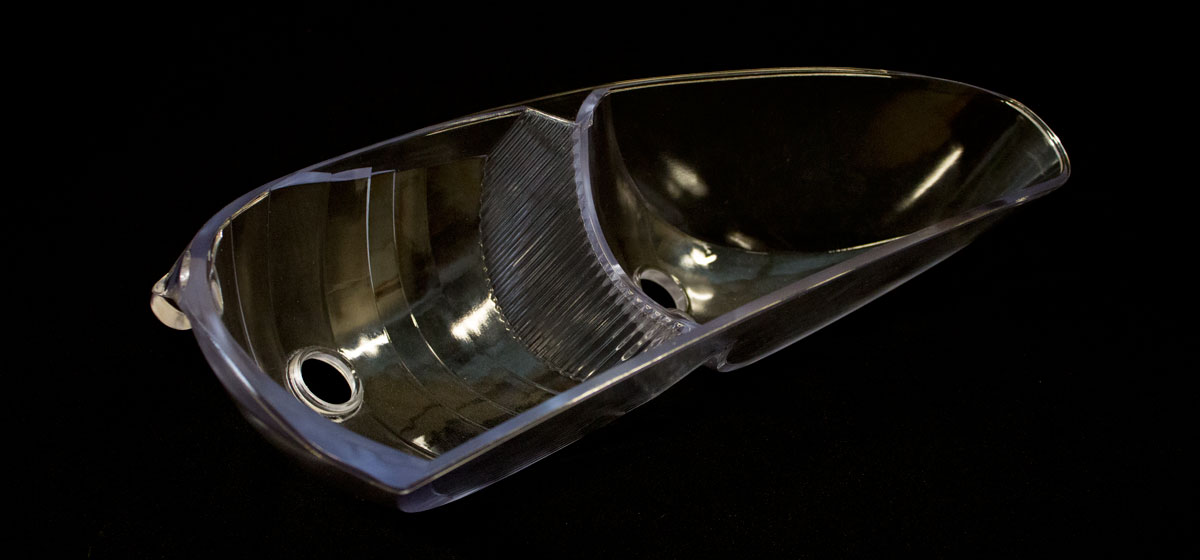

Plastics will thus continue to be the prime 3D printing material, with ABS and PLA demand fuelled by the rapid spread of consumer 3D printing systems, a trend which is expected to continue over the next five years. Metals demand will also continue to grow but they will remained confined to high end industrial applications due to high prices.

For both plastics and metals, M&M describes a market that is moderately fragmented. This could mean that is is an already mature market, or that it is still an extremely young market, which has not yet entered into the fragmentation phase and subsequent consolidation. Currently 3D Systems and Stratasys (plastics), Arcam AB and ExOne GmbH (metals) hold the largest market share in terms of production and supply.

Currently (as of 2013) North America is the prime consumer of 3D printing materials globally, although Europe and Asia together account for more than half of global consumption. M&M sees North America retaining its dominance through to 2019, with high investments from manufacturers due to growing demand.

Along with design software and 3D printing hardware, materials is one of the most important parts of the personal and digital manufacturing process. It is hard to argue against the proposition that the 3D printing materials segment is destined to grow exponentially, as new materials are developed and 3D printing technologies continue to expand their installed base and areas of application.

Categorically knowing how much this sector will be worth 5 years from now is very difficult, however, and M&M’s report lays a solid foundation for any further analysis and consequent adjustment, something that is necessary for any business planning. The one data that no one is doubting is that this is a rapidly growing market so, if you are thinking of developing or optimizing a new material for 3D printing, this is definitely the time to do it.