Developer of all-in-one 3D printing software, Simplify3D has just announced the release of their updated software suite. Simplify3D not only allows for the slicing and 3D printing of files, but also the ability to repair and preview prints before they make it into the physical world. With their latest release, the company has expanded 3D printer compatibility and added a number of features that are genuinely worth getting excited about.

Given the vast number of desktop machines, firmware, and software out there, Simplify3D claims a mission to unify the market. To do so, they’ve begun incorporating ever greater 3D printer support. Previously compatible with more than 100 printers, the company has added 19 more to their list, with Simplify3D Software CEO and Founder, Clayton Websiter, saying, “We provide a universal software platform that simplifies the process of 3D printing, regardless of the 3D printer you use. Our team tests each 3D printer and works directly with 3D printer manufacturers so the user has the best possible integration of hardware and software. The goal is a seamless out-of-the-box user experience. We currently support over 100 different 3D printers, and we are constantly adding new models to that list. With this release, we are pleased to add 19 new 3D printers to our Supported Printer List including the MakerBot 5th Generation, XYZprinting da Vinci and PowerSpec 3D printers.”

Webster adds, “We think broader compatibility will be a benefit for all parties involved. We hear from customers all the time asking which 3D printers are supported by our software package. We will be thrilled to tell them about all the new hardware platforms that are now compatible with their favorite software. It will help the manufacturers sell more 3D printers, and it gives the users more choices and functionality.”

The $140 software package has also been upgraded with some really neat features. With the ultimate goal of providing an extensive, all-in-one program for managing 3D prints in every way possible, the V2.2 release has, according to the company, the following capabilities:

•

A lightening fast slicer that saves time and encourages experimentation

• Mesh repair utilities to help prepare digital models for fabrication

• An animated print simulation that allows users to identify errors before printing

• Direct USB control of your 3D printer with a full-featured machine control panel

• Auto-generated support structures, or customized supports that can be added or removed with one-click for the best model construction and simple post-process cleanup

• The ability to use different settings within one model, unlocking many new possibilities for variable build properties

• Advanced features for multi-part builds, including tool path optimization algorithms that save time and improve part quality

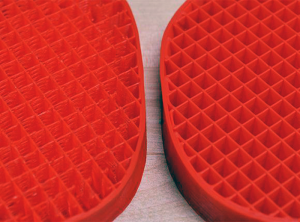

V2.2 opens up the ability to generate thicker print walls and infill when necessary for stronger parts. Support structures can also be customized to make for more robust support where needed and less dense in other portions. The new release also makes control over each nozzle in a dual extruder printer easier to control, to eliminate such headaches as oozing.

Webster explains the reasons for these updates, “Simplify3D Software spans the 3D community, giving users complete control over their 3D printers so they can produce stunning and precise results, regardless of the 3D printer being used. Our software is used by engineers, teachers, designers, medical technicians and hobbyists – anyone who want better quality models from their 3D printers. We want to make sure that the hardware is never limited by the software. Without great software, these amazing 3D printers are like driving a Ferrari on cruise control. There is so much more capability under the hood with these machines. The software matters.”

I’d love to get my hands on a trial version of the software, as it sounds like it brings some much needed control over the 3D printing process. And it’s gotten If you’d like to read how one artist has used Simplify3D to enhance his printing experience, see how Don Foley uses it to create his accurate models of high tech and historical objects.