Divergent 3D

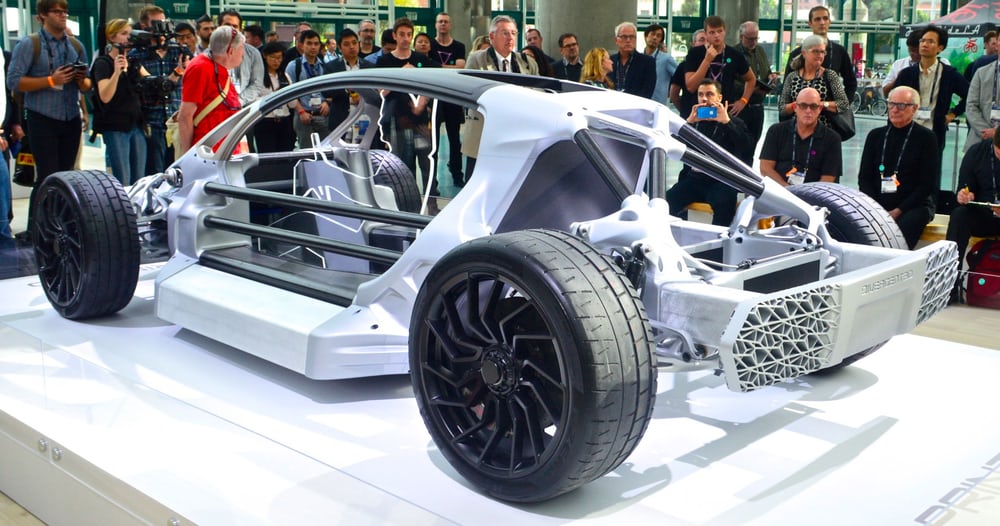

The LA Auto show is an annual event showcasing the latest innovations in car automotive technology. The latest leap forward at the show to involve 3D printing is an updated version of the Divergent Blade, the 3D printed super car. The show also features other companies like Jaguar, who have introduced 3D technology into their manufacturing process. The Divergent Blade is no gimmick, the car is fully functioning and can be considered a super car in more ways than one. The Blade can reach 60 miles per hour in just 2.2 seconds and has 700 horsepower contained in it’s 3.0 liter V8 engine.

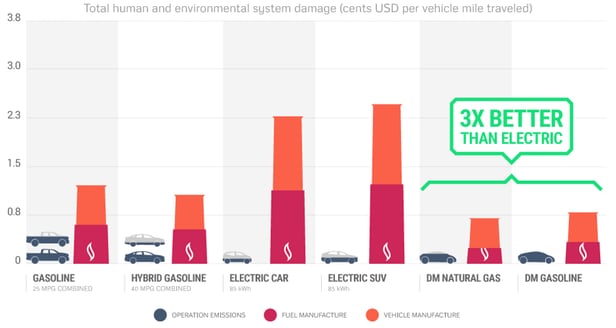

The main concern for Divergent is that while cars are becoming more environmentally friendly with the use of electric power sources, the manufacturing process is still as unsustainable as ever. One way to counteract this, according to Divergent, is through 3D printing. Divergent’s 3D printing process is coined ‘NODE’ and it involves 3D printing aluminium nodes which they combine with 3D printed carbon fiber tubes. There are many advantages to this technique; firstly the use of 3D printing in their factory helps to reduce emissions, secondly the car produced is considerably lighter compared to orthodox manufacturing techniques, and finally there is less waste as the number of materials used is reduced.

The car they have created is of course impressive but that isn’t the main aim for Divergent. The company wish to bring this 3D printing process to the masses and hope they can inspire other car companies to adopt their approach also. It seems that if car manufacturers are truly looking to reduce their emissions and produce more sustainable cars than they must start looking more at their manufacturing process like Divergent 3D. Car manufacturers will no longer be able use the excuse that 3D printed parts will affect performance and should start utilizing the technology with a number beginning to adopt it. Honda, for example, are looking into 3D printing parts along with Irish company MCOR.

Jaguar

Another company showcasing their use of new technology at the LA Auto Show is Jaguar. In order to recreate the classic XKSS model, Jaguar turned to a less traditional method: 3D scanning. Jaguar were recreating a classic car, only 16 of which were successfully made in their factory after the other 9 that were due to be made were destroyed in a fire. The recreation took 18 months involving 3D scanning in order to map the car, as well as using pictures of the original.

The classic British car manufacturer intend to create 9 more collectible cars in 2017, using this one-off as a model. The team behind the car wanted to reproduce the 1957 model in as much authenticity as they could which is why they turned to 3D scanning. The only differences between this model and the 1957 original were due to modern safety requirements. Since the original models were created by hand there were some unique aspects of the car which meant 3D scanning was necessary to map these peculiarities which could otherwise not have been explained. The automotive industry has become one of the many industries using 3D printing for advanced manufacturing, as 3DPI recently covered in another update here.

Featured image shows Divergent Blade at the LA Auto show. Image credit C.C. Weiss/New Atlas.