The month of July saw a plethora of partnerships and announcements from the Farnborough International Airshow as well as an abundance of funding for 3D printing startups in New Zealand.

Furthermore, the 3D printing industry welcomed a new range of filaments from Amazon, while observing the legal battle between Cody Wilson’s open-source 3D printed firearm file sharing site Defense Distributed and the U.S. government.

The Farnborough International Airshow

Located in Hampshire, UK, the biennial Farnborough International Airshow became the hub for partnerships aimed towards the advancement of industrial 3D printing in aerospace. Among the announcements is GE Additive, who launched a Manufacturing Partner Network (MPN). With initial partners including Burloak Technologies, Carpenter Co, and Proto Labs, the MPN strives to meet the increasing demand of 3D printed components.

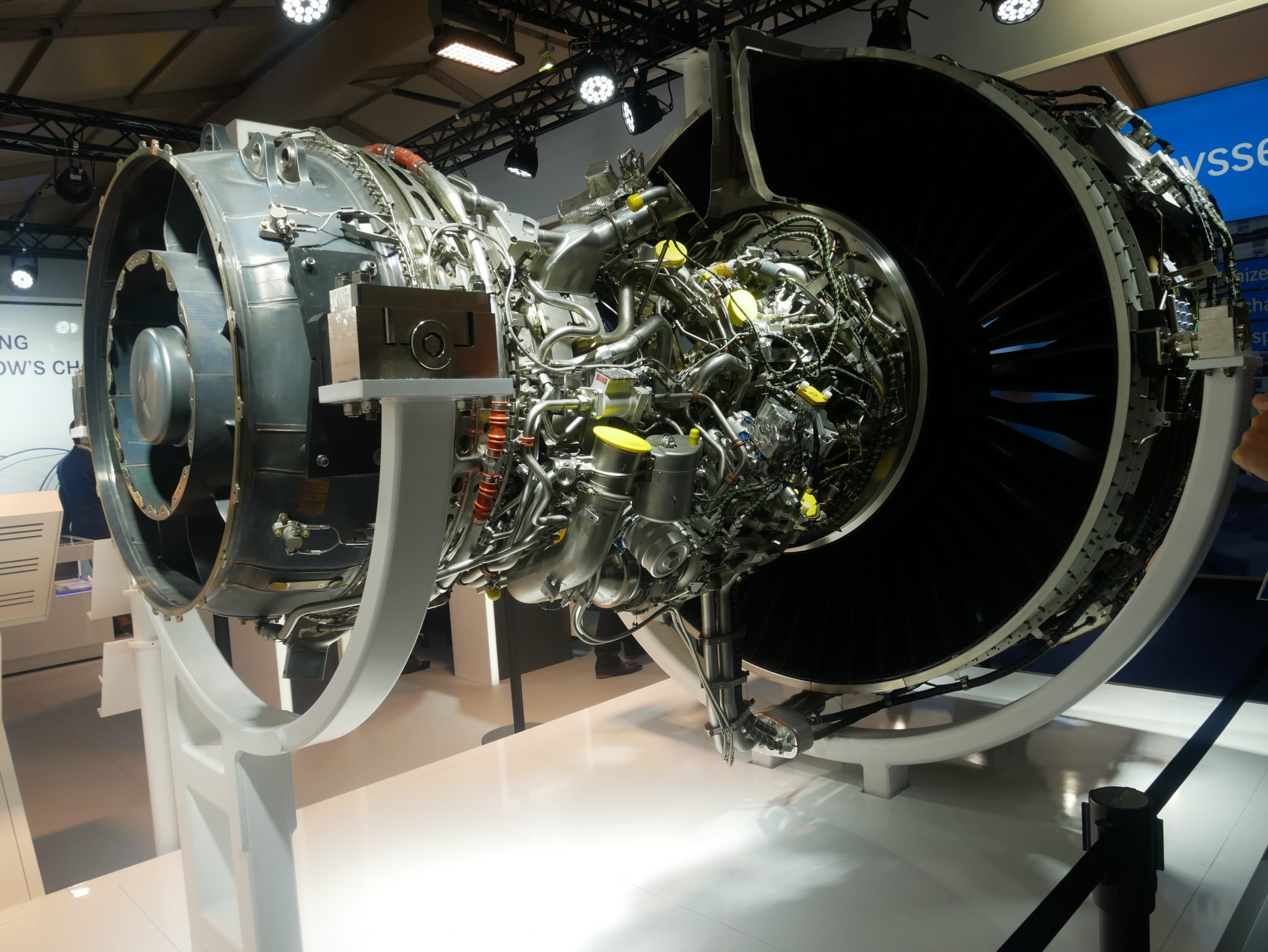

Furthermore, Norsk Titanium, an aerospace additive manufacturing company, in collaboration with The University of Notre Dame Turbomachinery Laboratory (NDTL), and Pratt & Whitney, created, tested, and displayed the first additive manufactured integrally bladed rotor (IBR) used within turbine engines.

Committing to industrial 3D printing

In business, Ricoh, a Japanese multinational imaging and electronics company, demonstrated its commitment to industrial 3D printing. Joji Tokunaga, president & CEO, confirmed a $1.8 billion budget for mergers and acquisitions for additive manufacturing and more.

In New Zealand, the Entrepreneurial Universities programme received a $10 million (NZD) boost from the Government and University of Auckland (UoA) to support 3D printing startups. Such funding has already helped to develop a 3D printed rocket motor from Kiwi startup Rocket Lab.

Additionally, Xometry, an on-demand manufacturing platform based in Maryland, acquired fellow manufacturing platform based in Kentucky, MakeTime, as well as a new funding round of $25 million.

Observing the investments in the market, Amazon launched its own brand of 3D printer filaments, AmazonBasics, which was tested and reviewed by our engineers.

“Low sales led to hard decisions”

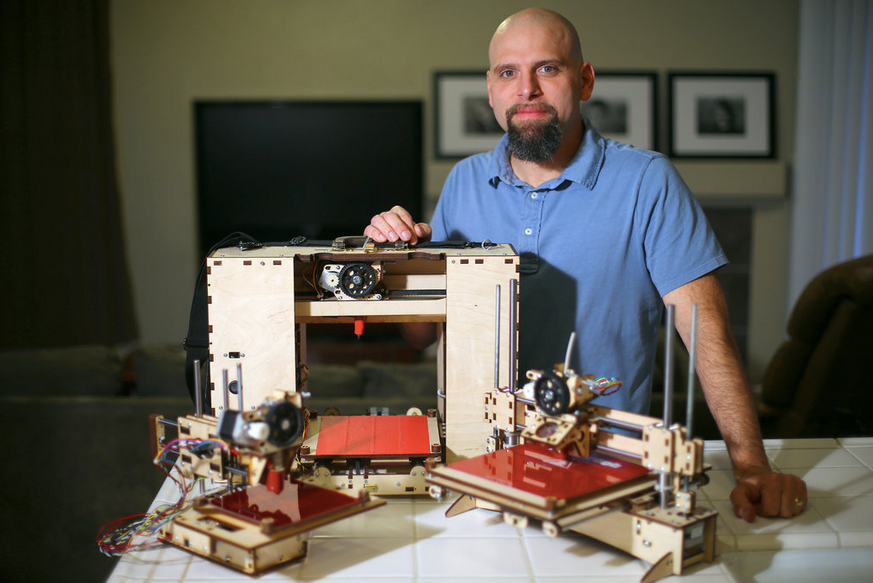

Despite the significant contributions to additive manufacturing, the 3D printing community was saddened by the closure of Open source 3D printer manufacturer Printrbot. Brook Drumm, founder of the company stated: citing poor sales as the reason for the decision. A simple statement on the Printrbot website from founder stated:

“Printrbot is closed. Low sales led to hard decisions. We will be forever grateful to all the people we met and served over the years. Thank you all.”

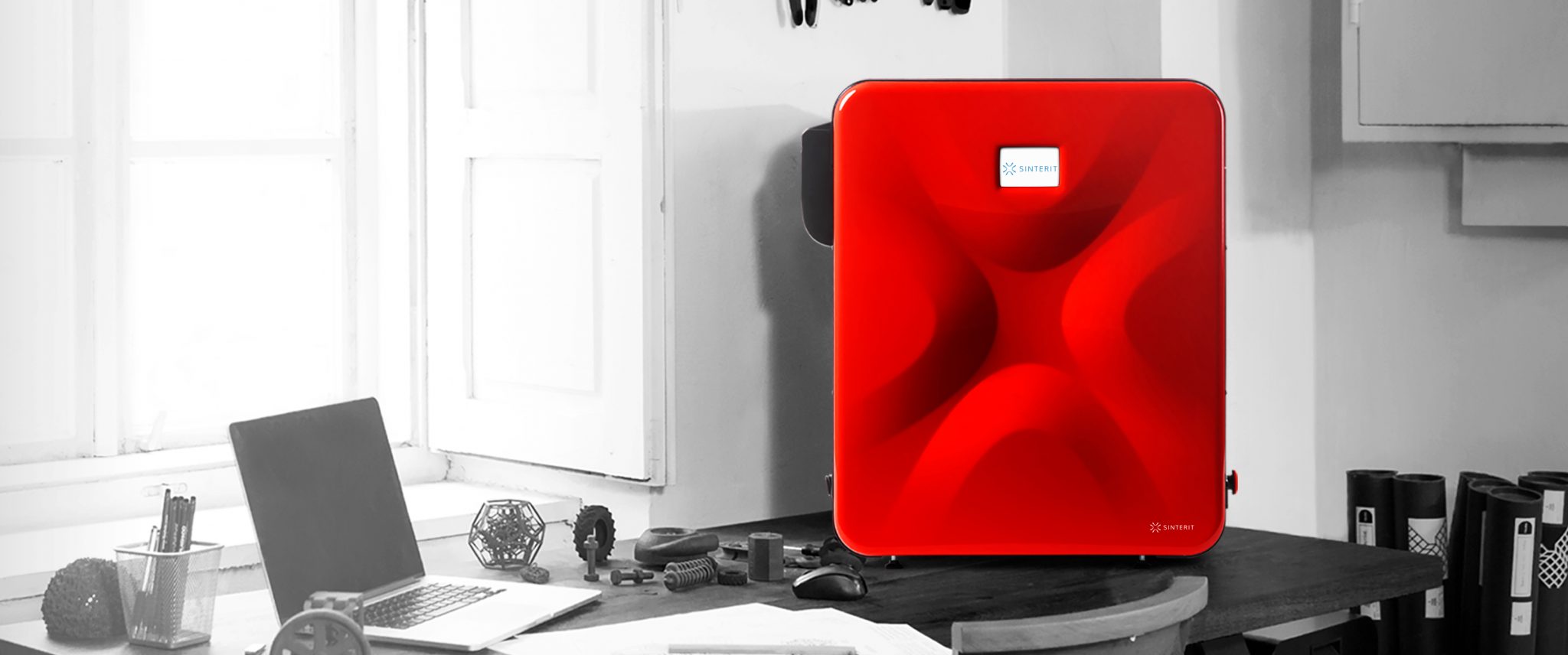

In other news, Sinterit, a Poland-based manufacturer of Selective Laser Sintering (SLS) 3D printers, revealed the LISA 1.5, a new generation of the market’s first affordable desktop SLS 3D printer – the LISA 1. This launch came two months after the release of the LISA 2, the desktop SLS 3D printer for industrial applications.

Trade wars and additive manufacturing

The beginning of July marked the start of U.S. trade tariffs on goods valued at $34 billion worth of imports from China. Considering the impact on additive manufacturing, Avi Reichental, Vice Chairman of DWS, told 3D Printing Industry:

“I think that China is a very important 3D printing marketplace – both as a supplier of increasing importance and for their strategic contributions. China is one of the countries that has invested the most in 3D printing in the last five years.”

“Industries like 3D printing and additive manufacturing thrive on the free and open trade of goods across borders and continents. We only have to remind ourselves that the best ideas and products might not come from our own backyard.”

The U.S Air Force’s Hot Cups

Home to the largest air mobility wing in the U.S. Air Force, the Travis Air Force Base in California used 3D printing to develop a cost-effective solution for replaceable handles on military-grade thermoses.

Lifting the 3D printed gun ban

Moreover, in a decision that caused upheaval, the U.S. Department of Defense (DOD) and U.S. Department of State (DOS) lifted the ban on Cody Wilson’s open-source 3D printed firearm file sharing site, Defense Distributed, which halted the distribution of 3D models of guns.

Who made the best contribution to the 3D printing industry? Make your nominations now for the 3D Printing Industry Awards 2019.

Also, for 3D Printing Industry updates throughout 2019 and beyond subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start in the new year? Visit 3D Printing Jobs to get a head start.

Featured image shows the Pratt & Whitney Geared Turbofan PW1000G aircraft engine, complete with additively manufactured components at Farnborough Airshow. Photo via Tia Vialva.