Aerospace and additive manufacturing news from the Farnborough International Airshow continues with a batch of news from Norsk Titanium.

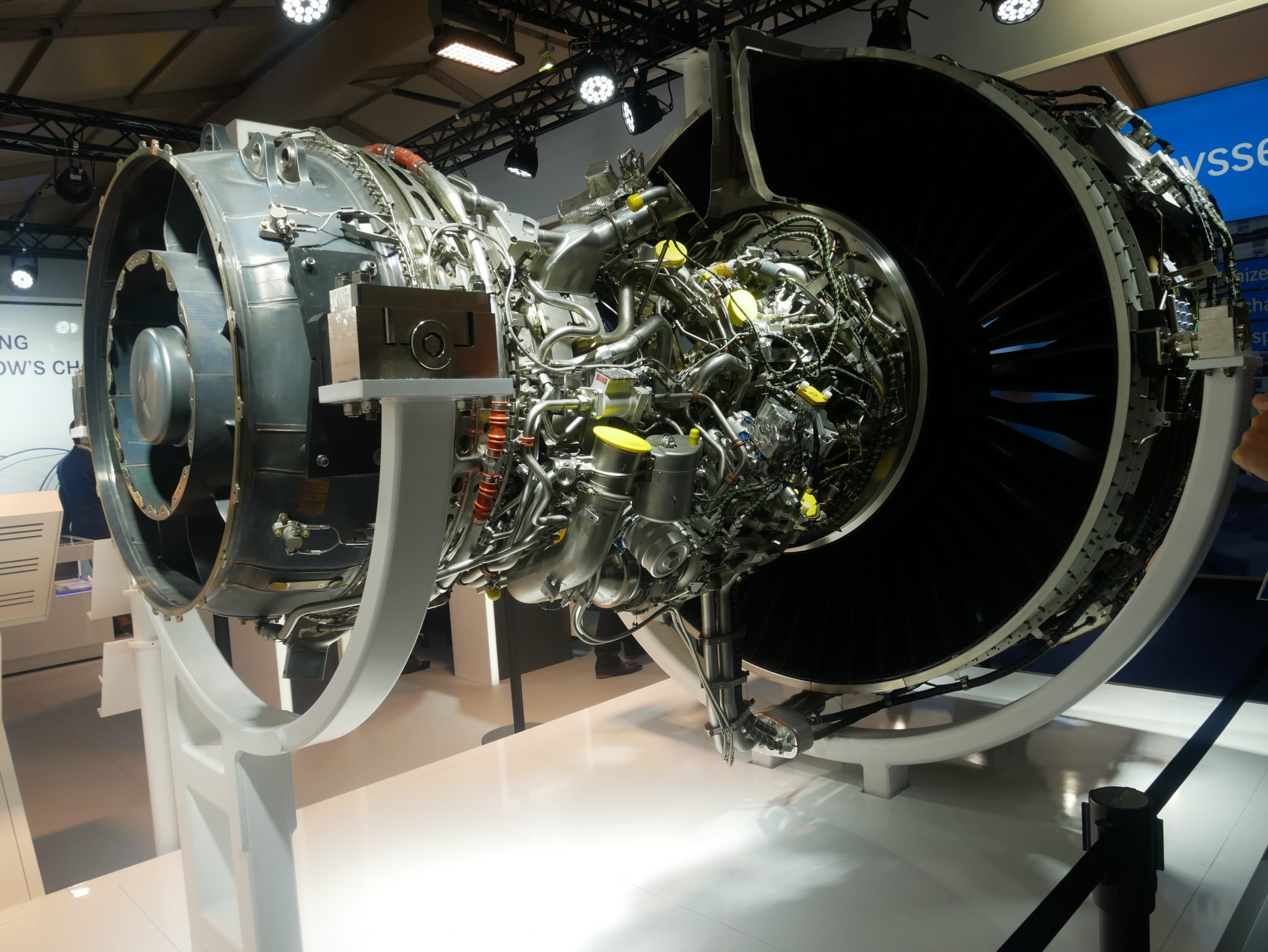

Norsk Titanium, an aerospace additive manufacturing company with headquarters in Norway, alongside a team of aerospace industry specialists, have collaborated to create and test the first additive manufactured integrally bladed rotor (IBR) used within turbine engines.

The University of Notre Dame Turbomachinery Laboratory (NDTL), Pratt & Whitney, an aerospace manufacturer based in Connecticut, and TURBOCAM International, a turbomachinery manufacturing company based in Barrington, New Hampshire, are included in the industry team.

“We are excited to collaborate on these manufacturing and testing efforts and applications for future engine development,” said Dave Carter, Senior Vice President, Engineering, at Pratt & Whitney.

Successful initial testing

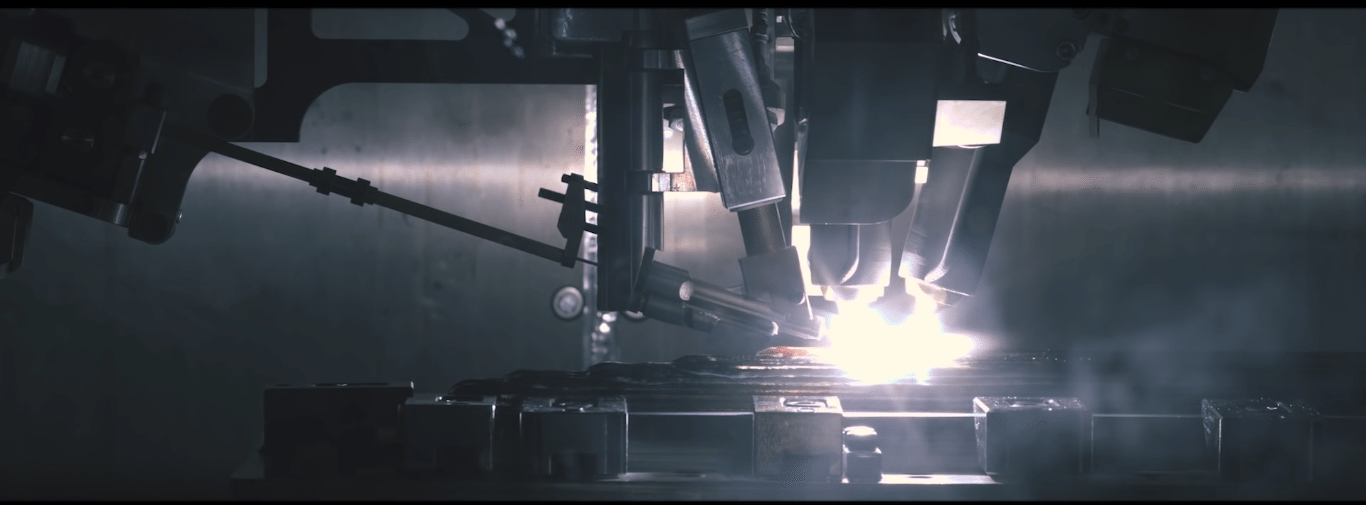

Norsk Titanium’s Rapid Plasma Deposition (RPD), is an additive manufacturing process using wired metal feedstock and argon gas to efficiently produce structural titanium parts.

Following the success of the RPD in producing the first additive manufactured part for Spirit AeroSystems, this collaboration is exploring its applicability in turbomachinery applications.

Within the initial phase of testing, TURBOCAM International conducted machining trials on the RPD material, then engineers at Pratt & Whitney inspected the material to the same specification as forged turbomachinery components. John Bressoud, General Manager of TURBOCAM Manufacturing stated:

“We were very pleased with the performance of the RPD material. We found no evidence of alpha case, and there were no residual stress concentrations that would cause distortions typically found in additive materials. The material was even more stable than what we would expect if we were machining a titanium forging.”

The next phase of testing will involve an additively manufactured IBR in an operational environment. This testing will be conducted using NDTL’s turbomachinery test facility.

Improved aircraft engines

The long-term goal of this collaboration is to develop cost and time effective manufacturing processes and tools to be used in more complex and heavily loaded turbomachinery components.

“We are thrilled to be working with world-class organizations dedicated to advancing the state-of-the-art in additive manufacturing and look forward to the next steps in developing qualified turbomachinery for the engine industry,” added Chet Fuller, Norsk’s Chief Commercial Officer.

The overall efforts of this joint venture are managed by Pratt & Whitney and will be evaluated for application for its future engine developments.

Pratt & Whitney has previously integrated additively manufactured parts in the production of its Geared Turbofan PW1500G and FT4000 aircraft engine systems.

Norsk Titanium partners with QuesTek Innovations

Recently announced at the Farnborough International Airshow (FIA), Norsk Titanium, and QuesTek Innovations, a materials developer based in Illinois, have partnered to create novel titanium alloys for additive manufacturing.

This collaboration has also leveraged Norsk’s Rapid Plasma Deposition (RPD) process and completed the first stages of evaluation on its QuesTek-designed titanium alloy.

“Norsk is continually evaluating new applications of our process beyond the structural airframe components in production today,” stated Nicholas Mayer, Vice President of Product Development at Norsk Titanium.

“QuesTek’s novel titanium alloy will allow RPD to grow into new applications and will allow designers to take further advantage of the benefits of additive processes.”

3D Printing Industry is reporting live from Farnborough International Airshow this week. Stay updated with the latest 3D printing news in aerospace by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace? Seeking new talent for your business? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the Norsk Titanium booth at the Farnborough International Airshow 2018. Photo by 3D Printing Industry.