In this week’s edition of the 3D Printing Industry news digest Sliced, you can find the latest stories from an expanding filament to mobile phone security, 3D printed art pieces at Milano Design, and life-size comic book characters.

We also cover the latest updates from the likes of Stratasys, Markforged, PyroGenesis and WASP. Read on for news regarding the latest patents, educational initiatives and product releases within the industry.

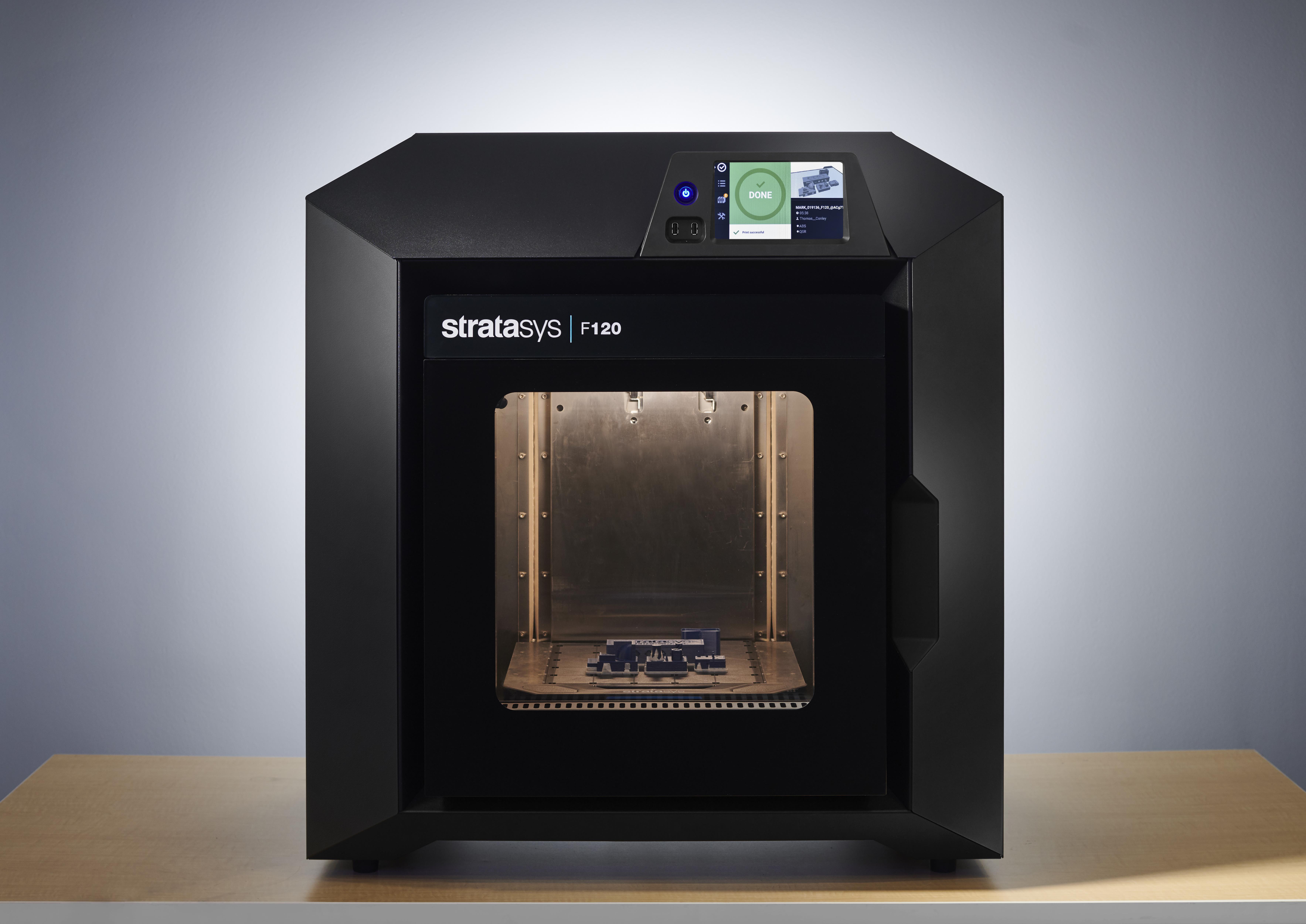

New Stratasys 3D printers available in the UK

The F120 3D printer, launched by Stratasys at AMUG 2018, is now available to UK customers through official company reseller SYS Systems. Aimed at making “industrial grade 3D printing more accessible”, the F120 is a compact solution that adds to Stratasys’ line of F123 FDM 3D printers (which also includes the F170, F270 and F370 systems).

Polyga Inc., a developer of 3D scanners and mesh processing software, has introduced two new models to its HDI Compact series of 3D scanners. The expansion means the HDI Compact line offers a wider range of solutions for digitizing different sized objects into 3D models. The new 3D scanners include the HDI Compact L6, for scanning large objects, and the HDI Compact C504, for digitizing extremely small objects.

“During rigorous testing, we used the HDI Compact C504 to scan a part as small as 1 cm in length and captured 3D scans with remarkable accuracy at just 6 microns,” commented Thomas Tong, President of Polyga Inc. “The macro 3D scanner works similar to a point and shoot for 3D scanning tiny objects. It can even capture minute details of an object difficult to see with the naked eye. This is quite an achievement for us.”

Expanding filament and other materials

Moving from hardware to new material releases, South Dakota-based 3D printing manufacturer B9Creations has introduced a new high-detail design resin, the HD Slate. Geared towards molding and model making, the resin is optimized for surface finish and creating detailed parts, with 20 μm slice thickness.

colorFabb, the Netherlands-based 3D printing materials company, has launched LW-PLA, a filament that uses an active foaming technology in order to create lightweight, low-density PLA parts. The material begins to foam when reaching temperatures of around 230°C, thus expanding up to three times its original size when 3D printed. This helps users to decrease material flow by 65% to achieve light weight parts.

Montreal-headquartered plasma torch specialist and metal powder producer PyroGenesis has manufactured titanium powder using its new NexGen Plasma Atomization System, which it unveiled in March 2019 as an upgrade to the original Plasma Atomization Process (PAP). The company revealed it has produced the titanium powder at a rate over 25kg/h with its new NexGen process, whilst maintaining lower operating and capital costs, establishing a significant cost per kilogram saving.

“A limiting factor in titanium adoption in the marketplace has been its cost,” stated Mr. Massimo Dattilo, Vice President of PyroGenesis Additive. “By lowering the cost of a typically expensive product, NexGen™ has opened the door to other markets and applications which, until now, found titanium to be too expensive to utilize.”

“We expect that the NexGen™ price reduction will drive an increased adoption of PyroGenesis’ powders into new markets and applications where the higher cost of plasma atomized powders was typically restrictive.”

The latest and upcoming 3D printing events

Milano Design Week 2019 , which was held from the 8th to the 14th April, has drawn to a close, and featured various art projects that were visualized with the help of 3D printing from Italian 3D printer manufacturer WASP. Of note amongst the various collaborations that WASP took part in, was the Conifera; an architectural installation made of seven hundred 3D printed bioplastic modules, produced with the Delta WASP 3MT INDUSTRIAL. The Conifera is a collaboration between COS, a London-based contemporary fashion brand, and French architect Arthur Mamou-Mani. Also showcased at Milano Design Week were the 3D printed ikebana vases created by Italian artist Andrea Salvatori, which were produced using the Delta WASP 40100 Clay 3D printer.

Boston-based and multi-award winning 3D printer manufacturer Markforged has announced the Metal X Roadshow, which will host over 60 open house events around the world. The events are designed to “equip manufacturers with the insight and expertise needed to join the next industrial revolution,” and will include sessions and demonstrations about additive manufacturing processes. Attendees will be able to get a look at the Metal X system from Markforged, and will learn the benefits of rapid metal 3D printing. You can find out the where nearest Metal X open house events are here.

“There’s been overwhelming excitement so far surrounding the Metal X Roadshow,” remarked Brian Houle, VP Global Channel Sales, Markforged. “The first few events have attracted hundreds of attendees interested in learning about 3D printing and our metal technology. When people see the Metal X in person, its applications as well as finished parts, they quickly realize the benefits to their organization.”

The UK’s Manufacturing Technologies Association (MTA) is hosting the first of its open access Technical Days, a half-day event that aims to promote and explain the benefits additive and digital manufacturing. Hosted at the Jaguar Experience Centre in Birmingham, UK on the 22nd May 2019, the event is free to attend and will connect companies and MTA members interested in the digital and additive manufacturing industries. You can view further details of the event and book you place now.

Unlocking your ‘childhood emotions’, and your smartphones

Comic book characters have been brought to life through 3D printing as part of the Angoulême International Comics Festival in France. MÉTROPOLE, a French large-format 3D printing specialist, has used a Massivit 1800 3D printer to produce five life-size statues of comic characters that have been placed at Angoulême station, dubbed as the world’s “comic book capital.” Beloved comic characters Blake and Mortimer, Spirou and Seccotine, as well as ‘Le Fauve’ – the festival’s mascot – are currently situated at the station to the delight of commuters and festival-goers alike.

“It took less than four weeks’ work – eighty hours of printing plus 200 hours of assembly, sculpting and painting – to create the five comics characters displayed at Angoulême station” commented Denise Zanet, Associate Director at MÉTROPOLE

“Comic fans love getting up close and personal with their favorite characters. This creates a strong bond both for children and the young at heart, who reconnect with their childhood emotions. No doubt lots of selfies with our statues will show up on social media.”

In other news, 3D printing recently attempted Mission Impossible, as it has been used to bypass the “ultrasonic” fingerprint scanner security lock on the Samsung Galaxy S10 smartphone.

Uploaded on Imgur from a user that goes by the name of ‘darkshark’, a video shows a 3D printed fingerprint being used to successfully unlock the Galaxy S10. The user acquired their own fingerprint from the side of a wine glass simply by taking a picture with their smartphone, and proceeded to run it through Adobe Photoshop, and then Autodesk’s 3ds Max, to produce a detailed 3D model of the fingerprint, which was then 3D printed using an AnyCubic Photon LCD resin printer. The video highlights a security vulnerability of the new phone from Samsung, considering the ease at which the user was able to replicate their own fingerprint and fool the mobile device.

The U.S. Marine Corps plans to use 3D printed impellers as a “stop-gap solution” for when the original impeller part becomes inoperable and a replacement part cannot be received in time. The 3D printed impellers will be used on the M1A1 Abrams main battle tanks, and is the result of a collaboration between Marine Corps Systems Command (MCSC), the Applied Physics Laboratory at the Johns Hopkins University, and the Defense Logistics Agency. MCSC has reported positive results after having qualified the 3D printed impeller for its performance, and so far it has not reported any wear or leakage.

“Right now, we don’t see any reason why the 3D-printed impeller is any less reliable than the OEM version,” explained Joseph Burns, technical lead for MCSC’s Advanced Manufacturing Operations Cell. “We plan to continue to collect operational hours on three 3D-printed impellers to better assess the long-term reliability of the part.”

Swiss art and design studio Drzach&Suchy has used 3D printing to create what it calls a “shattie” – a framed picture that uses shadow casting panels to conceal two images, which only become visible when illuminated in a certain way. Users can create and personalize their own 3D printed “relief” on the shattie website by uploading two pictures of their choice.

New advanced manufacturing facilities to boost Industry 4.0

Stanley Black & Decker, an American manufacturer of industrial tools and household hardware, is continuing its investment and development of 3D printing ventures. The company has now opened a 23,000 square foot Advanced Manufacturing Centre of Excellence, called ‘Manufactory 4.0’ in Hartford, Connecticut. The facility will help to accelerate Stanley Black & Decker’s adoption of advanced manufacturing technologies and spearhead its Industry 4.0 initiative. It will also be the home of the company’s STANLEY+Techstars additive manufacturing accelerator program, and comes after Stanley Black & Decker parterend with Astroprint to control and optimize its 3D printers through cloud-enabled software in March 2019.

The University of Technology Sydney (UTS) has also opened a new facility for advanced manufacturing called ProtoSpace. The facility aims to help grow advanced manufacturing in Australia and will provide an ‘open space’ for businesses of all sizes to use 3D printing technology, like the Nano Dimension Dragonfly 3D printer. Hervé Harvard, Director of ProtoSpace, stated “With some of the most advanced printers in the world, linked with academic expertise in using and extending 3D printing technology, ProtoSpace is delivering a unique resource to help achieve innovative Australian ideas,”

“We want to explore with them how 3D printing can add value to their businesses.”

Bringing 3D printing into schools

Taiwanese 3D printer manufacturer XYZprinting has revealed it will invest over one million dollars into its STEAM 3D Education Program, which aims to make 3D printing accessible to students in the classroom. The company recently launched a bundle scheme as well where a free 3D printer would be delivered alongside purchases of its K-12 STEAM curriculum, in order to encourage the educational market to make purchases in the program.

And finally, Korean biotechnology company T&R Biofab has reportedly registered a patent for its 3D bioprinting technology to create artificial skin. The technology operates through the 3D printing of dermal (inner layers of skin) and epidermal (outer layers of skin) cells that uses a porous 3D structure to form skin with similar characteristics to actual skin.

“This technology can be used effectively in a variety of areas such as assessing the efficacy and toxicity of newly developed therapeutic agents and cosmetics, and replacing animal experiments,” a company official said.

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo edited onto image of 3D printed cartoon character from Angouleme International Comics Festival. Original image via Massivit.