Desktop 3D scanners are an indispensable tool for applications including reverse engineering, product design, and art/architectural conservation.

In the latest release to meet the demand for versatile, high fidelity 3D scanning equipment Polyga Inc., a 3D scanning and mesh processing software provider, has launched a new line of High Definition Imaging (HDI) 3D scanners.

“We found there is a strong demand for a solution that has the ease of use of a consumer-grade 3D scanner but the output of a professional 3D scanning system,” explains Polyga president Thomas Tong.

“The HDI Compact 3D scanners cover all these bases. They are plug and play systems, ready to use right out of the box within minutes of setup.”

Super-fast capture

Polyga’s HDI Compact 3D scanners are made to be used on small objects, like dental impressions and car components.

Instead of gradually building a 3D image by sweeping over the surface of an object, a HDI Compact 3D scanner quickly captures a point cloud from what it can “see” directly within its field of view (FOV). As such, objects must be turned a few times, either by hand or on a rotary table, to make a complete digital image of the target object.

Available as three different models (the C109, C210 and C506), the HDI Compact has three possible FOVs: 68 mm x 87 mm – 87 mm x 88 mm, 71 mm x 98 mm – 100 mm x 154 mm, and 27 x 45 – 30 x 45.

Scan vision

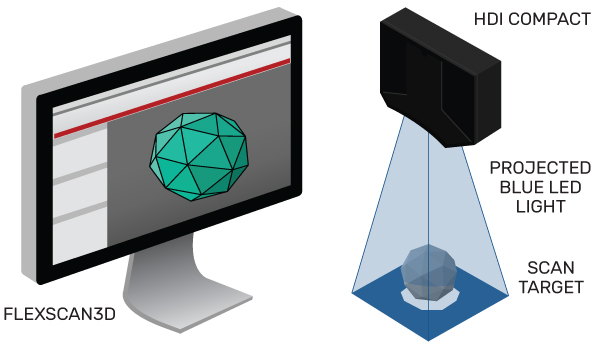

A Polyga HDI 3D scanner’s “vision” is powered by blue LED structured-light. In this process, a known light pattern is projected onto the surface of an object. The HDI 3D scanner then creates a point cloud with depth and structure based on the light that bounces back and enters its integrated cameras.

Depending upon the model of choice, a HDI Compact can capture objects at an average scan speed between 250 and 333 milliseconds. This equates to a resolution of 985,000 – 5 million points per scan.

Technical specifications

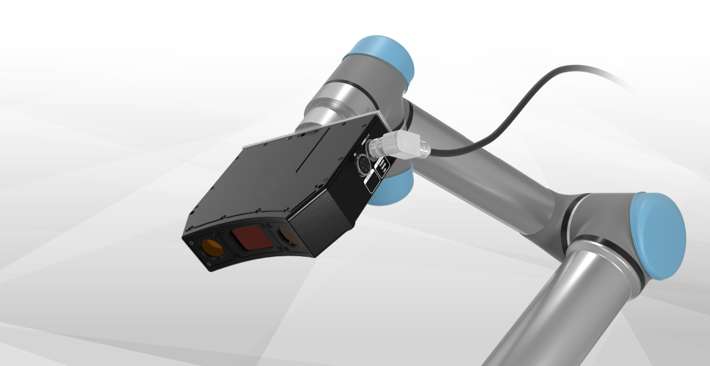

A versatile machine, the HDI Compact can be mounted on a variety of apparatus to meet specialized needs. With proprietary FlexScan3D software, Polyga is also offering a full turnkey solution for its 3D scanning technology.

In order to operate a HDI Compact, users must have at least a Windows 7 operating system, Quad-core Intel 2 GHz CPU, 4 GB of memory and 250 GB of free hard drive disk space.

For all of the latest 3D printing industry related product releases subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook here.

Nominate the best hardware and software in the 2018 3D Printing Industry Awards here.

Featured image shows a HDI C210 3D scanner and data sample. Image via Polyga