In this week’s edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments and partnerships throughout the industry. It also features a number of 3D printing applications in footwear, food, medical and construction. Furthermore, you’ll find an industry-wide research program detailing the countries with the greatest potential of implementing additive manufacturing.

Read on for the latest news from WASP, Farsoon, Massivit, Stratasys, Fabrisonic, Aurora Labs, APWORKS, Dassault Systèmes, VELO3D and more.

3D printing the perfect fit

Casca, a Canadian footwear start-up based in Vancouver, is offering a range of shoes with tailor-made 3D printed insoles, in order to provide the perfect fit for customers. They are made using a 3D model of the customer’s feet, produced via a mobile app capable of scanning a foot and mapping the data in a 20,000 point cloud. The insoles are 3D printed using 100% recyclable and non-toxic thermoplastic polyurethane-based materials.

In a creative use of 3D printing, Italian 3D printer manufacturer WASP has had its technology integrated into a hybrid machine that combines additive manufacturing with juicing. Named Feel the Peel, it is a circular food system created by Carlo Ratti, an innovation and design firm. Within the Feel the Peel prototype juicing system, orange peels are transformed into bioplastic through drying and milling. The bioplastic is heated and melted into 3D printing filament and used to feed a Delta WASP 2040 INDUSTRIAL 4.0 3D printer, also incorporated into the Feel the Peel system. This in turn is used to produce orange peel cups for customers to drink orange juice from.

French 3D visual communications specialist Deko 3D by Sepia has leveraged the large-format 3D printing technology of Massivit to help the company realize a number of its creative projects. Specifically utilizing the Massivit 1800 3D printer, Deko 3D has been able to create a 3D printed model of French professional footballer Gaëtane Thiney. The model was 3D printed for the 2019 FIFA Women’s World Cup, made using N3xtDimension UV-curable liquid resins from Sartomer, a subsidiary of French advanced materials company Arkema. Other models that Deko 3D has made using the Massivit 1800 includes a handball player, skier, and rugby player. The Massivit 1800 was also used to bring comic book characters to life for the Angoulême International Comics Festival in France earlier this year.

“3D printing provides a unique way for brands to reach and interact with their audience,” states Erez Zimerman, CEO of Massivit 3D. “And it is clear this is proving an attractive option for a number of key players in the sporting industry.”

What is Ultrasonic Additive Manufacturing?

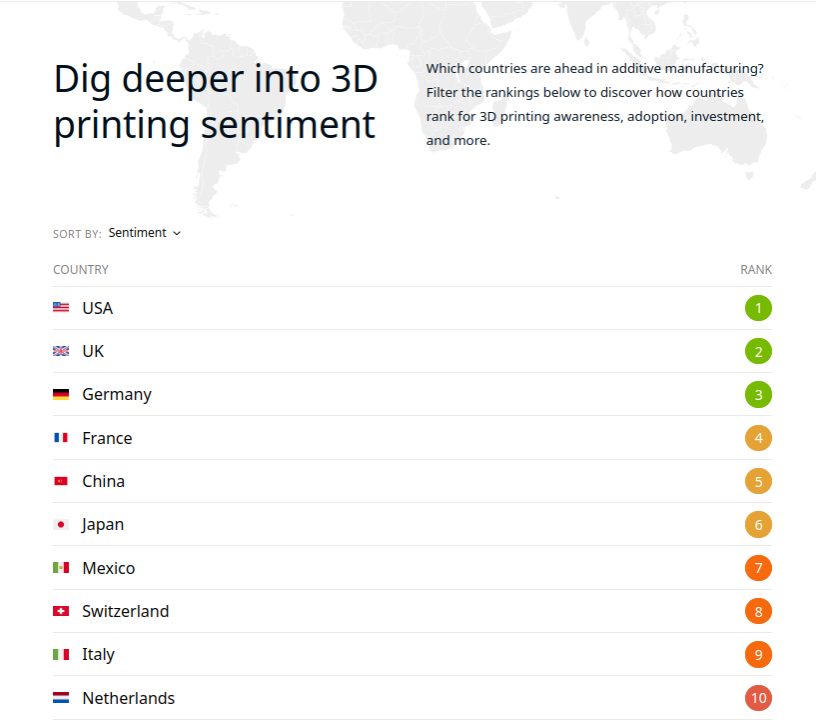

Desktop 3D printer manufacturer Ultimaker has released its first annual 3D Printing Sentiment Index, a dataset created to help the global 3D printing community monitor and identify growth opportunities. Using independent research conducted by Savanta, an international research firm, the index details a comprehensive view of the current and future potential for 3D printing in 12 countries worldwide, while covering the widest range of verticals and professions. According to the results of the research, the USA, UK, and Germany have the greatest expectations for implementing additive manufacturing, based on 2,548 interviews with qualified professionals and in-depth analysis of macro-economic factors.

“Sentiments are the start of a domino effect,” explains Rohit Jhamb, Director Global Research & Analytics at Ultimaker. “Positive sentiments lead to positive behaviour and investments, resulting in a future of significant and sustainable growth.”

“This research is the widest and most in-depth in terms of coverage that combines end customer voice with macro-economic indicators. It therefore offers a complete view of the current ecosystem and future growth potential for 3D printing and shows that we have moved past the hype often associated with 3D printing.”

Dr. Adam Hehr, a Research Engineer at Ohio-based metal 3D printing firm Fabrisonic, has published a technical paper exploring its patented ultrasonic additive manufacturing (UAM) technology. Titled “A Comprehensive Review of Ultrasonic Additive Manufacturing Technical Paper”, the paper aims to assemble in one location the history, technology advancements, application areas and research behind UAM.

3D printing in automotive and aerospace

In automotive this week, Bugatti’s record-breaking Chiron derivative, the first car to break the 300mph barrier, is equipped with 3D printed exhaust finishers produced by additive manufacturing consultancy APWORKS. 3D printed from titanium, the exhaust finishers are part of the modified longer tail section, designed to push the exhaust emissions further from the rear end of the car in order to reduce turbulence and improve steering behavior at high speeds. Utilizing the design freedom offered by 3D printing, the exhaust featured optimized aerodynamics which enabled increased downforce and higher speed handling of the car.

Over in Aerospace, Antemo, an Austrian engineering and manufacturing service bureau, has invested in a F900 3D printer from leading OEM Stratasys. Using the system, Antemo aims to advance its production operations and open up new business opportunities by reducing its per part production costs and accelerate overall throughput. The company will manufacture prototypes, production and small series parts for the aerospace industry, as well as healthcare and semiconductors.

“The ability to 3D print parts that are certifiable for the aerospace industry was not possible for us in previous years. As such, to date we have been using CNC milling and turning for our part production,” comments Martin Brunner, CEO, Antemo. “However, the Stratasys F900 3D Printer offers another dimension to our production insofar as both time and cost-savings; it allows us to by-pass lengthy and complicated programming, as well as expensive production costs associated with CNC milling.

European construction group Royal BAM will potentially be using its expertise in 3D printing to help build

London Heathrow Airport’s planned expansion. Having opened a 3D printing factory in the Netherlands in early 2019, the company plans further expansion with potential locations in the UK. London Heathrow, which has a large workload that needs completion for the expansion, is a potential customer for Royal BAM, which would be able to ship 3D printed components to the airport.

Material and hardware releases in the 3D printing industry

A number of new material and hardware releases to note of this week, as Italian 3D printer manufacturer SISMA introduced two 3D printers: the EVEMET 200 and the EVERES VARIO. The EVEMET 200 is a laser metal fusion 3D printer targeting the industrial and medical sectors. It is compatible with reactive metals and offers a maximum printing volume equal to a cylinder with a base diameter of 200 mm and a height of 200 mm. The EVERES VARIO, on the other hand, is a DLP system with a resolution of 3840 x 2160 px. Last year, SISMA released two new 3D printers in its EVERES family of DLP systems: the EVERES ZERO and EVERES UNO.

Wematter, a Swedish 3D printing startup, has launched a new post-processing hardware device for SLS 3D printing. Named the BlasThing Cabinet, it is designed to help users clean their SLS 3D printed parts in an easy and accessible manner. It uses a closed system with recirculating water and a filtering system to provide a powder-free approach for cleaning SLS 3D prints. The BlasThing Cabinet is designed to be used in conjunction with Wematter’s Gravity SLS 3D printer.

Japanese multinational imaging and electronics company Ricoh has launched a new powder material for selective laser sintering (SLS) additive manufacturing, suitable for the automotive industry. Ricoh is now offering PA6 for producing strong SLS components. PA6 is an unfilled Nylon 6 material with properties similar to those of injection moulded Nylon 6 parts, thus enabling the production of components where mechanical strength and heat stability are key requirements.

Partnerships and expansions

Various business partnerships and expansions have taken place throughout the industry this week. Stratasys has announced the appointment of TCL Hofmann and TCL Hunt as an authorized channel partner to expand its market outreach in both Australia and New Zealand. TCL Hunt is a supplier of industrial raw materials, semi-finished and finished products, and machinery based in New Zealand. In Australia, the company trades as TCL Hofmann, a wholly-owned subsidiary of TCL Hunt. The companies serve a number of industries, including plastics processing, food & beverage, packaging, pharmaceutical, medical and industrial.

“For many years we have seen 3D printing technology bringing an unprecedented revolution to many multinational enterprises, be it on-screen or behind the scene. The application potentials that professional-grade 3D printers can bring to Australian and New Zealand companies is huge and this is a very great moment to join the force,” commented Joseph Hancock, Managing Director, TCL Hofmann.

British engineering firm and metal 3D printer manufacturer Renishaw revealed that its profits dropped from £32.6m in 2018 to £4.3m at the same time this year. Attributed to “difficult economic conditions”, the company has also cut 22 jobs across its manufacturing sites throughout the UK.

Australian metal 3D printer manufacturer Aurora Labs has announced that it is currently in negotiations with several unnamed “leading global manufacturers” regarding purchases of its RMP-1 3D printer. Although no details regarding the clients were given, the company explains that should the evaluation and testing phases of the RMP-1 metal 3D printer prove successful, these companies have expressed an interest in buying the system. The RMP-1 3D printer entered the beta testing stages this year. Aurora Labs recently announced it has increased the speed of the system by a reported 2000%.

Californian metal 3D printer provider VELO3D has revealed that it has delivered its seventh Sapphire 3D printer to its largest production customer. The same customer has already ordered a total of 12 systems from Velo3D in the past year. These previously installed systems are in full production 3D printing critical aerospace components for the customer. “Our mission is to enable OEMs in aerospace and other key verticals to gain trust in 3D metal printing as a dependable manufacturing technology,” says Benny Buller, Founder, and CEO of Velo3D. “Our end-to-end solution enables users to adopt additive manufacturing without extensive redesign, increasing the viability of 3D metal printing of existing parts.”

Dassault Systèmes, the French developer of 3D design software SOLIDWORKS, has announced new milestones for its 3DEXPERIENCE Lab open innovation laboratory and accelerator program. The reach of the 3DEXPERIENCE platform has been extended by Dassault Systèmes with the introduction of new startups, incubator partners and fab lab partners into its global ecosystem. Fifteen new startups hailing from Belgium, China, France, India, South Africa, and the U.S. have joined the 3DEXPERIENCE Lab accelerator program.

Farsoon Technologies, a Chinese manufacturer of SLM and SLS 3D printers, has entered into a partnership with Voksel Rapid Manufacturing Technologies, a Turkish 3D printing reseller. Voksel will now be able to distribute Farsoon’s 3D printers in Turkey, in a bid from Farsoon to increase its global presence.

BASF, the largest chemical producer in the world, has begun construction of a $10-billion integrated petrochemicals project in China’s southern province of Guangdong. The facility, based in the city of Zhanjiang, will be China’s first wholly foreign-owned chemicals complex. Its primary purpose is for producing engineering plastics and thermoplastic polyurethane (TPU), materials often used in 3D printing. The company recently expanded its foothold in the 3D printing industry with the acquisition of the Paris-headquartered 3D printing service bureau Sculpteo.

CORE Industrial Partners, a Chicago-based private equity firm, has acquired ICOMold, a Shenzhen-based digital manufacturer with expertise in injection molding. This new transaction follows CORE’s acquisition of FATHOM, the on-demand additive manufacturing service provider, in September 2019.

Medical 3D printing prototype lab

Smart International, the authorized global brand licensee of KODAK 3D Printing, has announced a partnership with Colombian 3D printing non-profit organization e-NABLE Medellin. e-NABLE Medellin uses 3D printing technology to provide prosthetic limbs and assistive devices to children and adults. Smart International will supply customary 3D printing hardware, materials, and support to assist e-NABLE in achieving its goal to print and donate up to 35 prosthetic and assistive devices to those in need this year, and up to 60 in 2020.

AdventHealth Nicholson Center, a Florida-based medical research and training center, has officially launched a 3D printing Prototype Lab, allowing medical products to develop from concept to working prototype. Using 3D printing technology, CAD software, industry knowledge, and testing, healthcare professionals can develop their ideas for medical devices, and refine inventions to improve clinical outcomes. “Our expert team can help bring an idea from ‘napkin sketch’ to reality, and our 3D printing capabilities allow inventors to hold an actual version of their device in their hands for evaluation,” said Jodi Fails, B.S., Biomedical Engineer, and Prototype Lab lead at AdventHealth Nicholson Center.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo edited onto photo of Bugatti Cheron. Original Photo via Bugatti.