Australian metal 3D printer manufacturer Aurora Labs has reached a milestone for the commercialization of its RMP1 3D printer. After years in development, the team has finalized the construction, and now commenced live beta testing of the machine.

Before production, the RMP1 Beta 3D printer will undergo improvements and changes based on feedback from customers. A commercial version of the system is tipped for release later in 2019. David Budge, Managing Director at Aurora Labs, commented:

“The fact that the RMP1 Beta Printer is operational is a key milestone for the team here. Developing and refining our technology has been long in the making and the RMP1 Beta Printer is now built and ready to go live.”

“We are transitioning from a heavy R&D phase with the RMP1 Beta Printer and we will now be able to move to a commercialization and sales stage much more strongly with the technology we have developed.”

Aurora Labs moves closer towards optimum 3D printing speed

Metal 3D printing at Aurora Labs is conducted using Rapid Manufacturing Technology (RMT) – a method seeking to attain faster printing speeds than any other machine on the market. RMT uses another Aurora-developed process, Multi Concurrent Printing (MCP), to simultaneously lays down, melts and fuses multiple layers of powder.

In 2018, tests for RMT demonstrated the technology printing at 662g/h or 15.88 kg per day, however in an interview with Nathan Henry, Director of Marketing and Business Development at Aurora Labs, stated that it was “still too slow” for the company, which was “expecting to at least double that speed in our smaller machine which is going to be the RMP1.”

Since then, further tests and improvements by Aurora has enabled its RMT process to achieve increased print speeds of 113 kg per day. David Budge described the improvement as “the latest in a long line of impressive developments since the company’s inception in 2014.”

The company recently closed a AU$5 million (US$3.5 million) share placement round to help further develop RMT. With RMT implemented within the RMP1, the company has anticipated a high speed production rate of 30 kilos per hour for the system. Henry explains that “[RMT] is being developed with a focus on addressing the need to make things at a speed that makes it economic.”

Prioritizing speed and quality

The RMP1 Beta Printer has a print bed measuring 450 mm x 400 mm, which can reportedly 3D print parts in volumes 10 times the scale of those produced with the Alpha2 3D printer (Aurora’s previous test machine), with three times the processing capacity. With the beta printer functional, and all primary sub-systems operating, the company’s next step is to commission and test the 3D printer through machine calibration, printing tests and sample part production. Using the Alpha machines, parameters for initial print materials have already been developed, allowing for minimal testing of the RMP1 Beta Printer to speed up the commercialization process.

Further to the upgraded design, the RMP1 Beta Printer is also expected to provide a significant speed increase over the previous testing machine using its MCP technology. David Budge adds: “We have prioritized optimizing speed increases and print quality which are key pillars of the Aurora strategy, and the team has made substantial progress achieving speed increases throughout the last few months, resulting in the print of a series of 10mm high, titanium hexagon parts in a timeframe of only 20 minutes.”

Aurora will be holding an open day once it has commissioned the RMP1 Beta Printer, inviting additive manufacturing industry partners, investors and key players to view its new technology.

Keeping it within the industry

Preliminary discussions are already underway at Aurora regarding the potential sale of the RMP1 Beta Printer to an industry partner following beta tests. Industry partnerships are considered important to enable the future growth of the company, which has been in contact with a number of parties from its industry partner program as part of Aurora’s sales pipeline.

The company prefers that, in the event of a sale of the beta system, the user is also locked into purchasing Aurora powders for the life of the machine. Using Aurora’s powders in conjunction with its 3D printers is key to the ecosystem of the company, while also ensuring the production of quality parts. Aurora is engaging with various potential interested parties as it looks to secure pre-orders for future machines. The company is confident it can garner sales from the machine, with a reported high level of interest at recent trade shows, including AMUG. Budge concludes, stating:

“We are also encouraged by the expressions of interest received from multiple parties for the RMP1 Beta Printer and look forward to updating the market with Aurora’s developments ahead.”

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

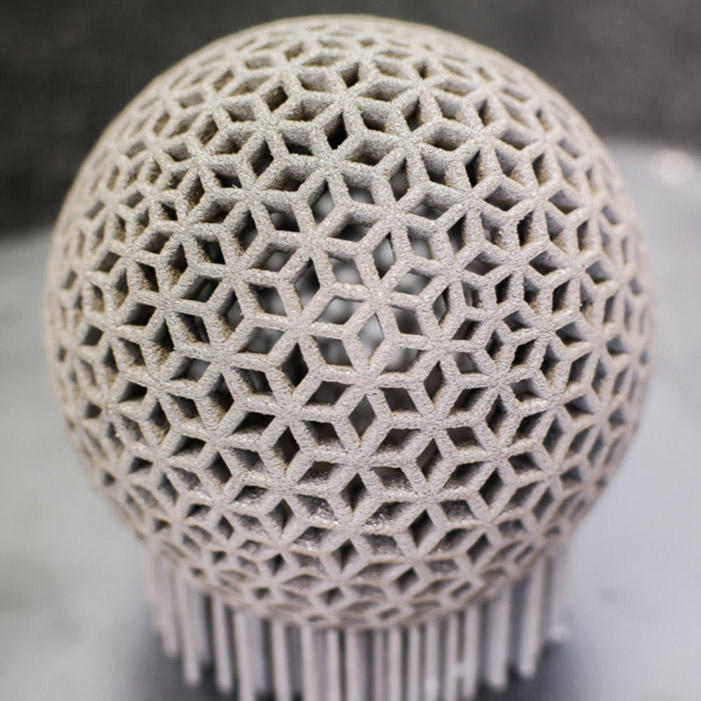

Featured image shows the first component printed using RMT. Photo via Aurora Labs.