Wematter, a Swedish startup company, has launched a new SLS 3D printer named Gravity 2020.

Built for use in office or workshop environments, the Gravity 2020 is designed to 3D print durable SLS components. It is the latest iteration of Wematter’s Gravity system, and comes with an ecosystem to support engineers in its installation and use, particularly when applied to the production of parts favorable mechanical properties.

“Mechanical properties and ease of use has always been our main targets and we think it is the best path for changing behaviour towards additive manufacturing,” comments Robert Kniola, founder and CEO at Wematter.

The Gravity 2020 3D printer is currently shipping out to customers that have collaborated with Wematter during its development. It is also available for pre-orders to those that did not take part in Wematter’s development process.

Making SLS 3D printing easier

Founded in 2014, Wematter is focused on developing SLS 3D printers, specifically to help lower the barriers of adopting SLS technology, and thus increase the use of additive manufacturing overall.

Its founders, Robert Kniola and Henrik Lundgren, have experience in working with injection moulding and milling, as well as FDM, SLA and SLS 3D printing. Working with this knowledge of the industry, the founders identified a gap in the market to provide SLS 3D printing in a more accessible, easy-to-use way. The Gravity 2020 is part of Wematter’s solution to this market challenge. It has been in development at the company for a number of years, having undergone several iterations. To help maximize its ease of installation, this latest version only requires one 230v 10A power socket, and one ethernet connection, for operation.

“We have worked hard to only use a standard 230v 10A socket and to comply with CE-regulations for IT-equipment so minimize the installation effort from our customers” adds Kniola.

The Gravity 2020 3D printer

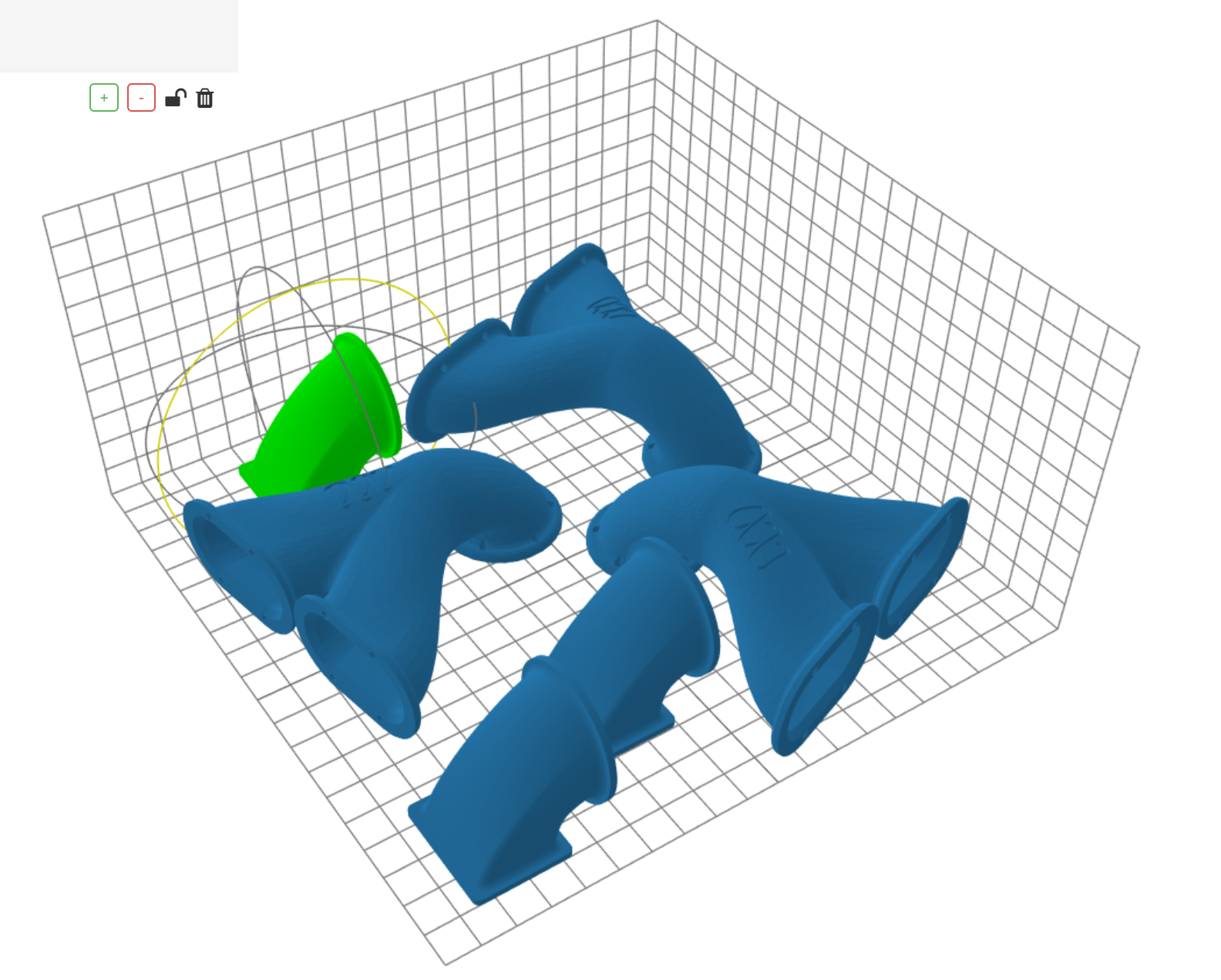

The Gravity 2020 3D printer has a build volume of 300 x 300 x 300 mm. It is equipped with an integrated powder handling system to help further improve the ease of use, utilizing pneumatic systems to help transport, dose and evacuate powder in a closed system.

The system is cloud-ready, enabling monitoring and process control over its in-built sensors, camera and electronics. To send print jobs from any device, including computer, cell-phone and tablet, Wematter has developed its own Deep Space print preparation software that utilizes the Gravity 2020’s cloud connectivity.

After the user uploads their .stl or .step files, the Deep Space software is then able to stack and queue 3D models using algorithms. “We have put productivity and user-friendliness in focus so that more people can discover the benefits of Additive manufacturing.” comments Petter Johansson, VP of Engineering at Wematter.

Wematter is in the process of developing more materials for the Gravity 2020. The machine gets shipped with Wematter Aurora, a PA11 based material. The company has also co-developed a nano-cellulosa based powder over the last three years, and has begun a research project seeking to introduce graphene based conductive materials for SLS 3D-printing. Henrik Lundgren, Co-founder and process manager explains the roadmap for Wematter’s material development: “The team is expanding rapidly and we will introduce new materials to the market the coming years to come. Our target focus right now is repeatability, durability and high precision in the process and the components.”

Accessible SLS 3D printing

Various manufacturers are introducing low cost SLS 3D printers in order to establish more accessible and production-oriented SLS systems.

Polish 3D printing firm Sinterit is one example that has focused on making cost-effective SLS 3D printers to help increase the technology’s accessibility. Its LISA 2 system, for example, is designed to be an affordable and easy to use SLS 3D printer, much like its first generation of 3D printers.

Switzerland-based 3D printer manufacturer Sintratec has also made significant efforts in making SLS 3D printing more accessible through its Sintratec Kit system. Although it requires assembly upon purchase, it can be bought for €4,990.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Wematter Gravity 2020. Photo via Wematter.