This week’s edition of Sliced, the 3D Printing Industry news digest, features the latest developments of additive manufacturing in fashion, footwear, and art, as well as novel research in tissue engineering to combat cardiovascular disease.

The latest news from Farsoon Technologies, Rize, Titomic, 3D Systems, Formlabs, Protolabs, Dassault Systèmes, and others can be found prior to Formnext, the leading additive manufacturing conference hosted in Frankfurt, Germany.

3D printing the Sisters in Liberty

Freshmade 3D, an Ohio-based model design company, has unveiled a 9ft 3D printed replica of Pio Fedi’s Liberty of Poetry statue, which resides at the Opera di Santa Croce in Florence, Italy. 3D scan data was taken from this statue, which is said to have inspired the Statue of Liberty, to create 3D printed sand molds on an ExOne system. Freshmade 3D’s AMClad material was also used to facilitate the molds.

The 3D printed replica statue is on display at the Ellis Island National Museum of Immigration in New York City in an exhibit, titled “Sisters in Liberty: From Florence, Italy to New York New York”. This is a collaboration between Kent State University (KSU) and the Opera di Santa Croce.

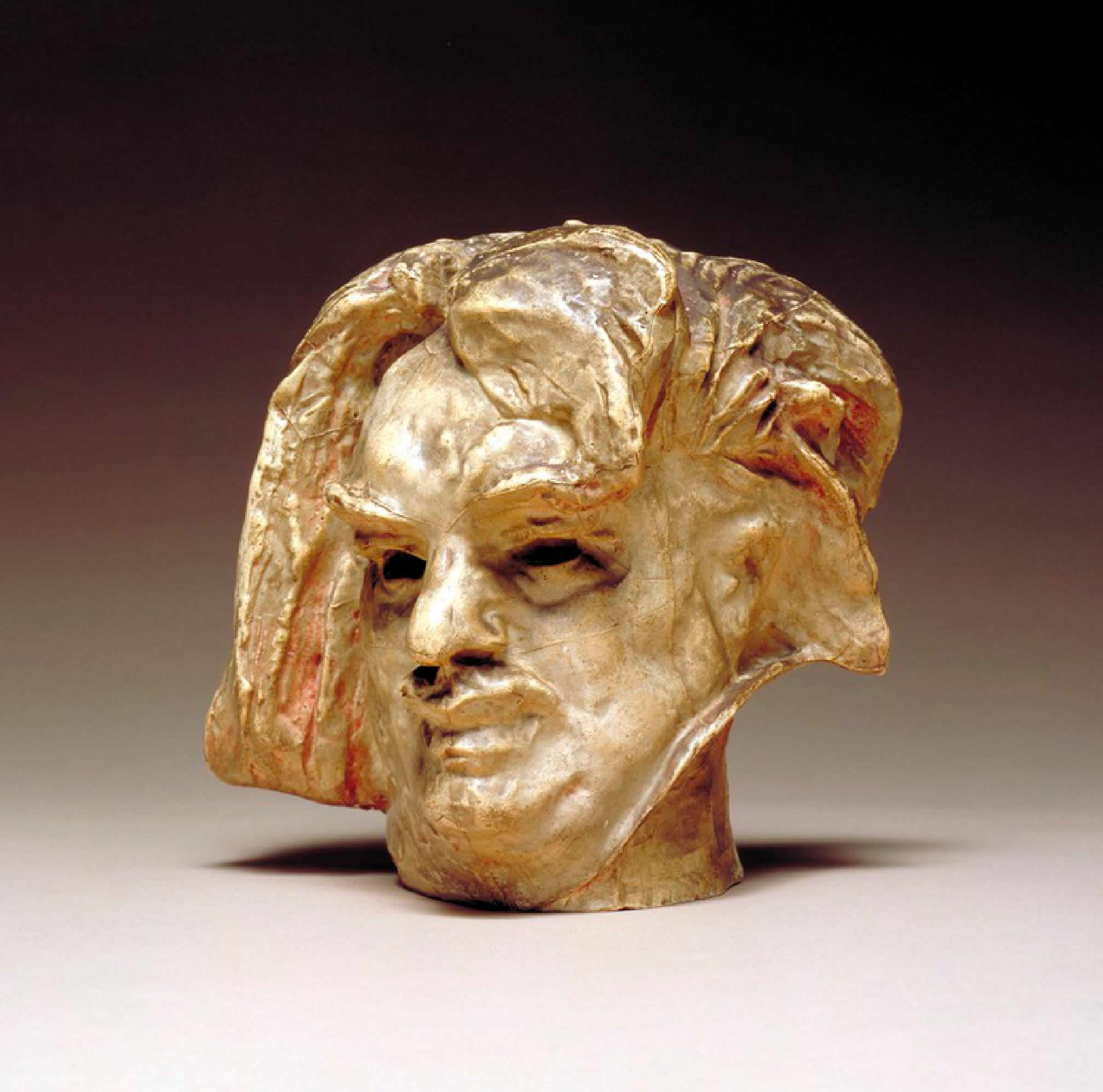

NVision, a 3D scanning solutions provider headquartered in Southlake, Texas and the Nasher Sculpture Center in Dallas, has 3D printed various scale replicas of prolific sculptures for the blind and visually impaired. These works include Auguste Rodin’s Hanako and Head of Balzac, and Julio González’s Mask: Reclining Head.

“Who has not been tempted to touch an artwork by a master like Rodin? These scans make that wish possible for everyone to experience,” said Lynda Wilbur, Manager of Tour Programs at the Nasher Sculpture Center.

“It is particularly meaningful when visually enjoying the lines, textures and emotive qualities of work are not possible due to blindness. These scans of works by significant artists of the 20th century allow our public a rare, hands-on experience.”

Fashion, footwear and additive manufacturing

The Italian luxury fashion house, Giorgio Armani, has leveraged its large-format Massivit 3D printer to create an eagle buckle measuring 6.9ft x 3.9ft, for a billboard campaign. The 3D printed buckle took 29 hours to produce and was then finished by Colorzenith Milan.

In New York, Alexis Walsh, an artist and designer, has debuted the EXO Collection, a fashion line with 3D printed accessories and pieces. On the outskirts of Paris, France, Erpro Group has installed its 11th additive manufacturing system, the EOS P396 through Erpro 3D Factory.

Bulleit Frontier Whiskey, a Kentucky-based whiskey maker, has collaborated with Dallas-based street artist Kyle Steed and industrial design firm Tangible Creative to create a limited edition run of 3D printed trainers. The “first of a kind” shoes can be purchased at $250 on Sneaker Politics.

Camper, a Spanish footwear company, has streamlined its creative process for its annual collection with rapid prototyping using 3D printing technology from BCN3D Technologies.

Protolabs, an award-winning on-demand manufacturing provider, is now offering a £100,000 in its European Cool Ideas Awards scheme for creators and early-stage companies to realize innovative products using 3D printing. This grant, which doubles the prize money of its initial scheme, is also providing support for contestants who do not win but have been recognized by the judges. For more information on the Cool Idea Awards click here.

3D printed ophthalmic lens specialist Luxexcel, based in headquartered in Turnhout, Belgium, has created a custom high power prism reader lens for a U.S. lab client wanting to sell an upgraded low-vision aide.

Research, construction, and 3D printing

In construction, Vertico, a Netherlands-based 3D concrete printing specialist, and the Department of Architectural Design and Engineering at the Eindhoven University of Technology (TU/e) have created three monolithic 3D printed columns, standing 3 meters tall and weighing 300kg each. These structures were showcased at the ‘Drivers of Change’ exhibition at Dutch Design Week in Strijp-T last month.

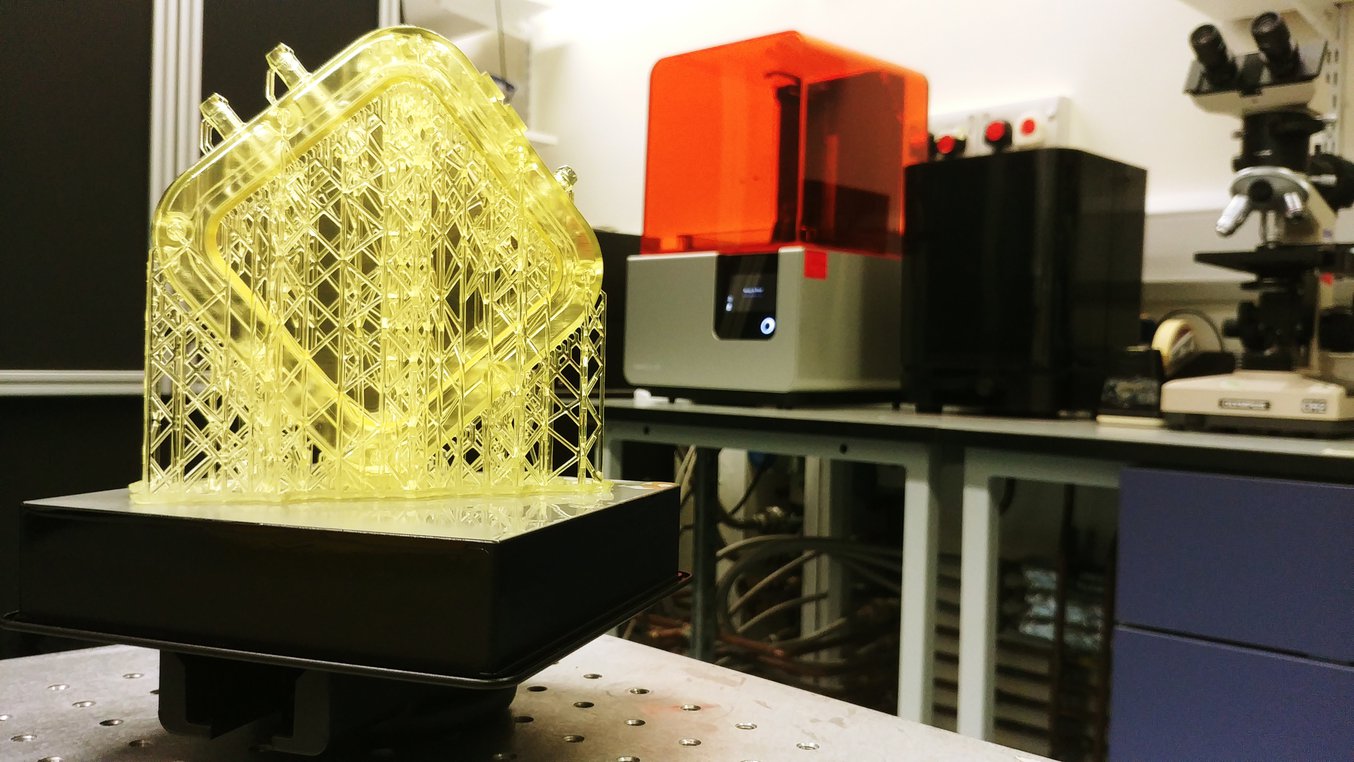

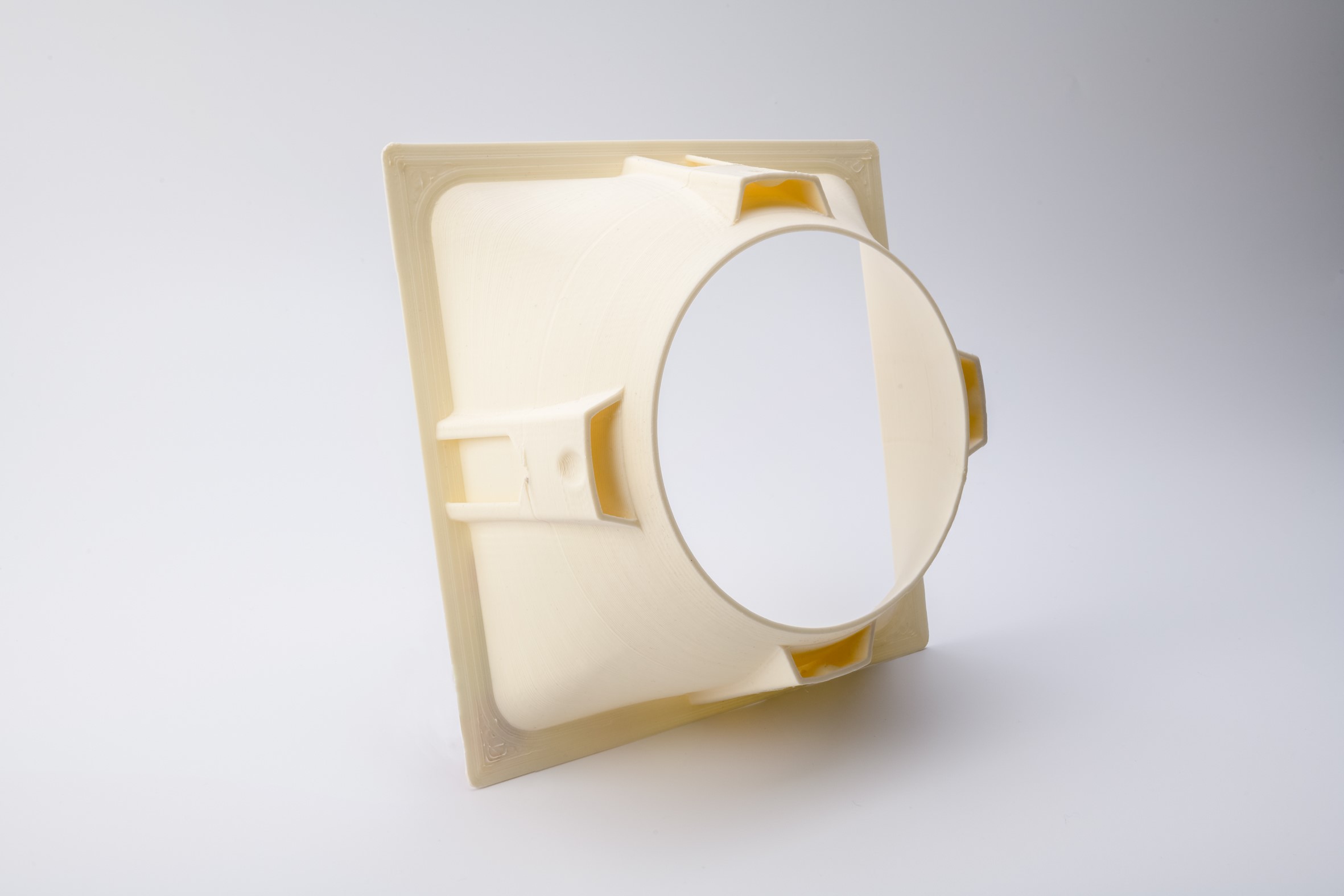

Dr. Sam Pashneh-Tala, Research Fellow at the University of Sheffield, is using Formlabs 3D printing technology to enable the production of complex tissue-engineered blood vessels that aid surgery for cardiovascular disease. This addresses the lack of availability of autografts for invasive surgeries as well as synthetic vascular grafts that are prone to infection and clotting.

“Previously, I would have paid between £270-£300 to outsource the manufacture of a polycarbonate bioreactor chamber,” added Dr. Pashneh-Tala. “With my Form 2, I am able to print the design in my lab using Dental SG, a biocompatible and autoclavable material, for £30-£40. The chamber is then easily sterilized and ready to be used straight away.”

Researchers from Aalto University, Finland, and Michigan Technological University, have used 3D printing to create an affordable air-bearing platform with three degrees of freedom of angular motion. This aims to improve the accessibility of testing environments for nanosatellites. The study, “Design and Testing of a Low-Cost, OpenSource, 3D Printed Air-Bearing-BasedAttitude Simulator for CubeSat Satellites” can be accessed here.

Automotive and naval developments

The Technology and Innovation Laboratory (T&I Lab) of Norfolk Naval Shipyard (NNSY) in Portsmouth, Virginia, is exploring the use of 3D printing for a more innovative workforce. Jessica Roberts, Additive Manufacturing Subcommittee Lead, explained:

“Innovation is another word for improving our products and processes to best fit with our modernizing workforce. In order to best explore the new technologies we have access to, it’s important to put forward the research and explore ideas of what AM is best suited for here at the yard.”

SembMarine, a Shipbuilding and repairing company based in Singapore, has received certifications from DNV GL to qualify its 3D printing procedures and specifications for parts used in its construction and repair projects.

HRE Wheels, a California-based wheel manufacturer, has introduced the Series S1SC in collaboration with GE Additive. This is a two-piece forged wheel line offering greater stiffness, reduced mass, higher concentricity and eliminates the air seal required of traditional three-piece wheels.

Furthermore, BMW i Ventures, has announced an investment in ELISE, a startup developing generative engineering software aimed at automating the product development process.

In other news, King Agro, a John Deere company manufacturing carbon fiber for agriculture applications, is using the Kodak Portrait 3D printer to produce jigs and fixtures into its production line. As a result, the company has reduced maintenance, R&D, Quality control and production costs by approximately 99%.

Moreover, Dremel DigiLab, the educational division of U.S. tool manufacturer Dremel, has released the new firmware version R02.08.08 for its 3D45 3D printer. To learn more about upgrading your 3D45 3D printer clicker here.

3D printing and business

Farsoon Technologies, a Chinese manufacturer of SLM and SLS 3D printers, has celebrated its 10th anniversary as well as the AM Innovation & Industrialization Forum at its headquarters in Changsha. The company has also announced the commercial availability of its HT1001P Continuous Additive Manufacturing Solution (CAMS) following a successful beta program.

Elsewhere, Collins Aerospace has received the 17th annual Nondestructive Testing (NTD) Innovation Award presented by Airlines for America and SAE International for the novel use of 3D Computed Tomography (CT) to advance aircraft structural inspection.

3devo, the Dutch makers of the Next 1.0 Industrial Desktop Filament Extruder, has announced its expansion to North America with a new office in Claymont, Delaware. As stated by Tim Wesselink, CEO of 3devo, a U.S. presence will help the company improve the purchasing process for its overseas clients.

Leading 3D printer OEM 3D Systems has partnered with ZVerse to integrate its CAD as a Service (CADaaS) platform. Hiperbaric, a Spanish supplier of high-pressure processing (HPP) equipment for the food industry, has launched Hot Isostatic Pressing (HIP) machinery for post-processing of 3D printed metal parts.

On the last two days of October, large-format 3D printer manufacturer BigRep and RedCabin partnered to host the Global Additive Applications Summit (GAAS) in Berlin. Martin Back, Managing Director at BigRep, explained:

“As a leader in industrial AM solutions we are invested in growing processes, materials, applications, and their effective implementation to push modern manufacturing forward. The GAAS is showing how additive technology’s focus is evolving from prototyping to production of end-use parts, thereby becoming an accessible serial production technology.”

Titomic, an Australian additive manufacturing company, has reportedly surpassed ASTM International Standards using Titomic Kinetic Fusion (TKF). As part of a $2.6 million research project, the TKF process used CP Titanium Grade two powder to achieve 3D printed parts with ultimate tensile strength (UTS) of 634Mpa, 83.8% higher than 345Mpa3set by ASTM International. This process also produced parts with an increased elongation of up to 27.7%, 38.5% higher than 20%3 set by ASTM International.

ProtoCAM, a 3D printing service bureau based in Pennsylvania, has achieved ISO 9001:2015 certification. Bob Holbrook, the Vice President of Sales and Marketing at ProtoCAM, stated, “In achieving our certification, we can now proudly provide our customers the highest standards of quality assurance for all of their prototyping and production requirements.”

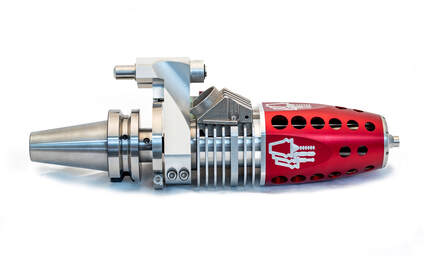

Hybrid Manufacturing Technologies has introduced its patented AMBIT PE-1 extrusion head for CNC machinery adopting additive manufacturing capabilities. The company’s CEO, Jason Jones, explained:

“The AMBIT PE-1 extruder is the most practical path for machine shops to adopt additive manufacturing. It is ideal for quickly producing parts, jigs, and fixtures in-house. The advancement of the AMBIT™ PE-1 extruder continues our commitment to broadening the industrial adoption of Additive Manufacturing like never before.”

RIZE Inc. has named Inceptra, the largest Dassault Systèmes 3DEXPERIENCE solutions partner in North America, as a new value-added reseller. This move is said to significantly expand access to RIZE’s 3D printing platforms in this region.

In Zhenjiang, China, Jiangsu University has installed the first MetalFAB1 system from Additive Industries within its Marine Equipment Technology Institute (METI). In addition, Kennametal, a Pennsylvania-based supplier of tooling and industrial materials, has launched a new additive manufacturing business unit.

miniFactory, a Finnish industrial FDM/FFF 3D printer manufacturer, has launched the miniFactory Aarni – Process Monitoring System, which visualizes and certifies 3D printed part data to be produced on its Ultra high-temperature additive manufacturing system.

Materials launches and partnerships

Infinite Materials Solutions, a Wisconsin-based materials developer, have introduced Aquasys 120, a high-performance, water-soluble 3D printing support material designed to be compatible with a range of filament at high temperatures. The company will be showcasing AquaSys 120 at Formnext in hall 12.1, booth G41 next week.

Airwolf 3D, a California-based 3D printer manufacturer, has been issued with the U.S. Patent No. 10,428,248 for compositions, materials, and methods for enhancing 3D printer platform adhesion by the United States Patent and Trademark Office.

German metal 3D printer manufacturer SLM Solutions has qualified a low-alloyed copper-alloy for additive manufacturing known as CuNi2SiCr.

Michigan-headquartered material develops, XGSciences, and Terrafilum, an eco-friendly filament supplier, have partnered to develop 3D printing filaments and coatings using graphene-based materials.

Chris Jackson, President of Terrafilum, adds, “The full potential for 3D printing is starting to be unlocked. The addition of XG’s graphene formulations into our eco-friendly filaments will transform products allowing a greater variety of parts to be created at faster production rates using less energy.”

Global science-based company and material producer DSM has introduced Novamid AM1030 FR, a new flame-retardant filament material, which is the first UL Blue Card-certified filament for open systems. This PA6/66 material is designed for applications in the automotive and electronics sectors. The company has also partnered with Twikit, a Belgian personalization software provider, to co-develop new 3D printed solutions for medical, automotive, and apparel applications.

Subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter for all the latest additive manufacturing news. Also visit 3D Printing Jobs for new opportunities in additive manufacturing.

Featured image shows the Sliced logo over the 3D printed shoe designed by Kyle Steed, Bulleit, and Tangible Creative. Photo via Kyle Steed.