The 3D printing arm of KODAK, the New York-based imaging technology company, has expanded its range of materials and accessory for its Portrait 3D printer.

Through Smart International, the authorized global brand licensee of KODAK 3D Printing, Acrylic and Nylon 6/66/12, as well as mirrored E3D hotends, have been introduced for higher quality, more durable 3D printed models.

“The market demand for 3D printing is ever-evolving, and KODAK 3D Printing aims to be a forerunner in bringing new innovations to life,” said Roberto Gawianski, CEO of Smart International.

“Every new material and accessory we develop is application-driven, aimed at solving engineering problems with parts capable of withstanding a wider and wider range of resistances and industry needs.”

Kodak 3D Printing materials

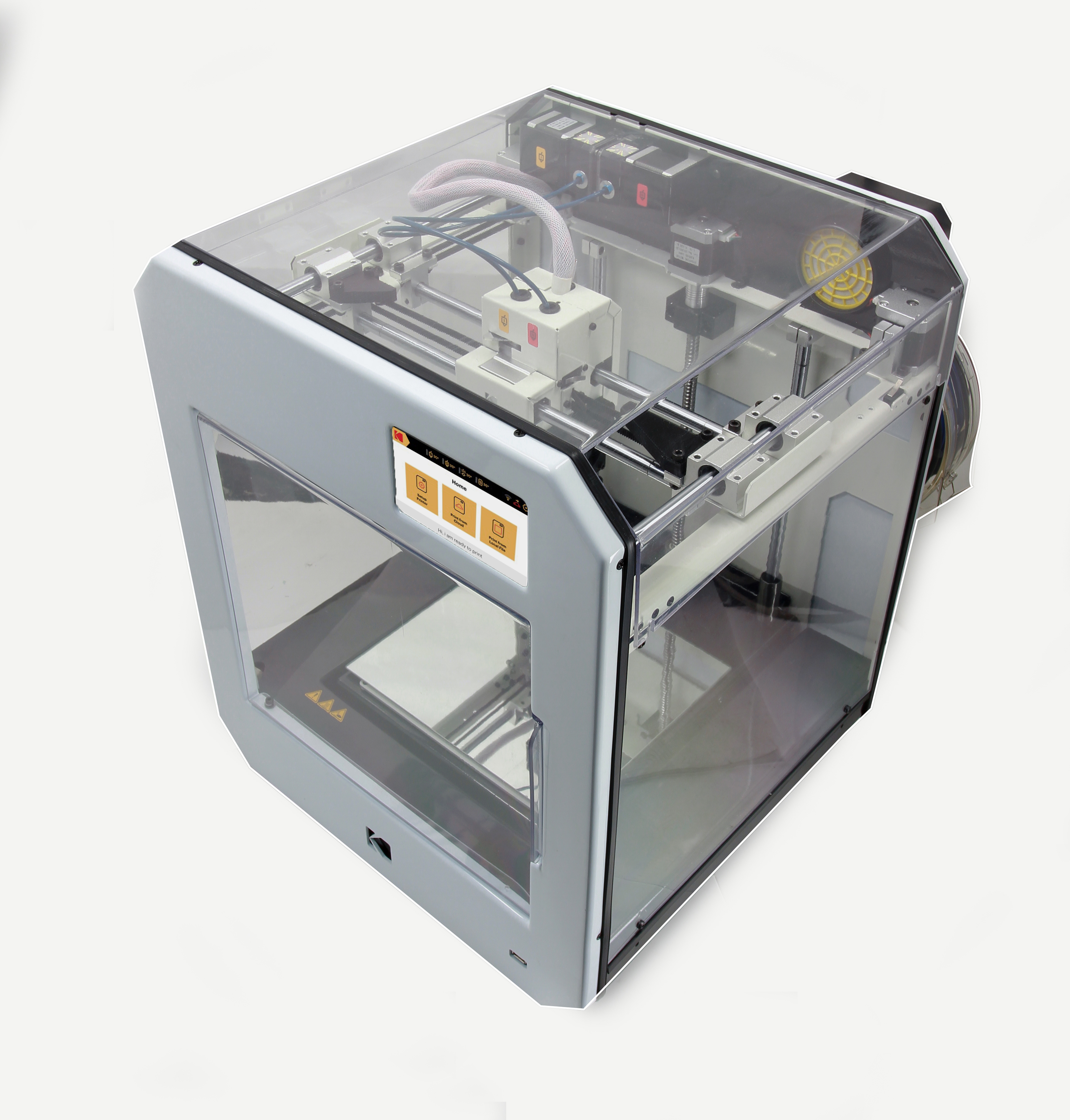

In 2017, Kodak announced its move into the 3D printing industry with the Portrait 3D printer, a system with dual extrusion capabilities and a fully enclosed build chamber with air filtration. Kodak’s low moisture filaments for the Portrait range from PLA, PLA Tough, ABS, HIPS, Nylon 6 and Flex.

The new Acrylic filament combines polycarbonate properties for high rigidity and light conductivity. This material has been designed for optical applications, that is, parts requiring high transparency. Moreover, the new Acrylic is low-friction and can withstand high temperatures. Its is also low friction coefficient, enabling it for moveable parts.

Furthermore, Nylon 6/66/12 is designed with greater flexibility. Unlike traditional Nylons, it is low warping and allows for fine details and overhangs. This material is also suitable for strong parts with tensile resistance.

Advancing dual FFF/FDM additive manufacturing

Also complementing the Portrait 3D printer, Kodak is adding several accessories to its system. The first to be introduced are two mirrored E3D hotends, one all-metal and the other PTFE. This allows users to replace an existing hotend for 2 all-metals or 2 PTFE on the same machine, ultimately providing dual material prints for two high or low-temperature materials, in addition to two-color combinations.

Earlier this year, the company announced its ‘Design to Print Service’, which aims to assist its users in transforming their ideas into a 3D printed product. As part of the service, experts from the Kodak 3D Printing team are on-hand to help troubleshoot time-consuming or difficult tasks for its customers that are using its 3D printing technologies.

You can keep up with additive manufacturing news by subscribing to the 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D printed nylon turbine part. Photo via Kodak.