Under a new agreement, leading additive manufacturing technology supplier EOS will be contributing to aircraft maintenance, repair and overhaul (MRO) at Etihad Airways Engineering.

The largest MRO service in the Middle East, Etihad has been ramping up its 3D printing efforts in recent years including a partnership with large scale 3D printer manufacturer BigRep, and work with Siemens, and aerostructure manufacturer Strata Manufacturing.

“Etihad constantly invests in new technology and has identified additive manufacturing as a key technology for aviation interior parts, as well as applications beyond aerospace in the future,” says Bernhard Randerath, Vice President Design, Engineering and Innovation at Etihad Airways Engineering.

“The technology is a key enabler when it comes to design and innovation in our industry.”

A 3D printed cabin interior

At present, the end goal of the EOS collaboration is to produce 3D printed cabin interiors, using polymer technology. Toward this end, Etihad Airways has already installed 3D printed screen surrounds into the seats of its airplanes.

In order to expand on these capabilities, EOS will first have to qualify the machine, process and materials used to make cabin parts in accordance with aviation regulation.

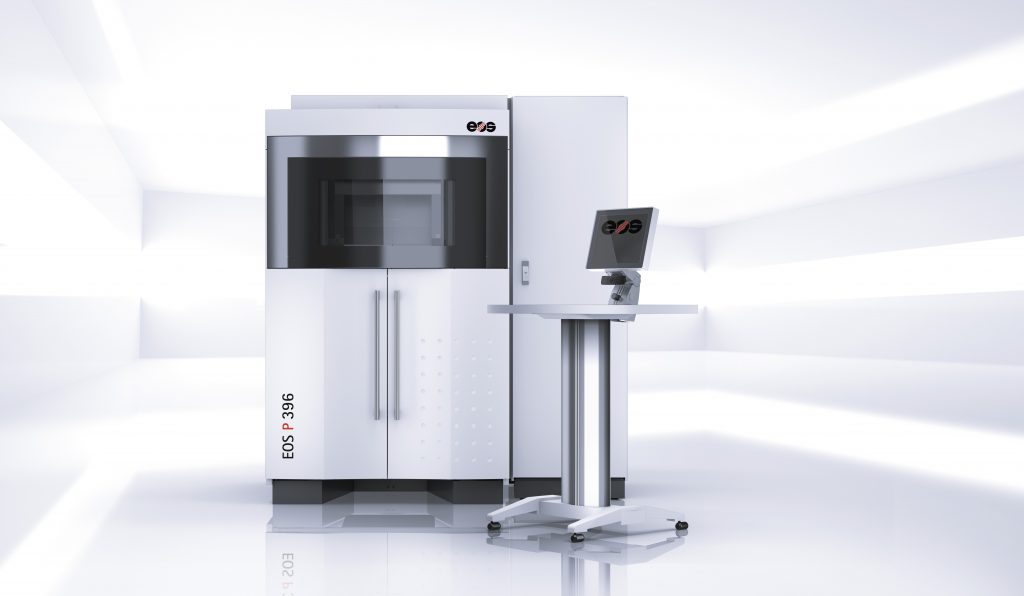

The EOS P 396 is at the center of the “EOS system for additive manufacturing” which will be applied to the task. It has a medium build volume of 340 x 340 x 600 mm, with improved energy consumption over its predecessor the EOSINT P 395. It is completed by an IPCM P plus mechanical powder handling system.

Taking production to the next level

After qualification, EOS and Etihad will then work together to develop aerospace-grade materials and industry-specific additive manufacturing capabilities. Eventually, the plan is to roll-out EOS 3D printing abilities across the broader Etihad ecosystem.

Markus Glasser, Senior Vice President Export Region at EOS, concludes, “Etihad is providing industry-leading aircraft maintenance and engineering solutions, […] We are honored to support our partner on this innovation journey, as such bringing the production of aircraft interior parts to the next level.”

For all of the latest 3D printing in aerospace and business news follow 3D Printing Industry on Twitter, like us on Facebook and subscribe to our newsletter.

Search and post 3D Printing Jobs to find new opportunities and talent in this growing industry.

Featured image shows Markus Glasser, Senior Vice President Export Region at EOS (left) shaking hands with Bernhard Randerath, Vice President Design, Engineering and Innovation at Etihad Airways Engineering. Photo via EOS