Formlabs, Somerville-based manufacturer of SLA 3D printers, has announced its new material, Tough 1500.

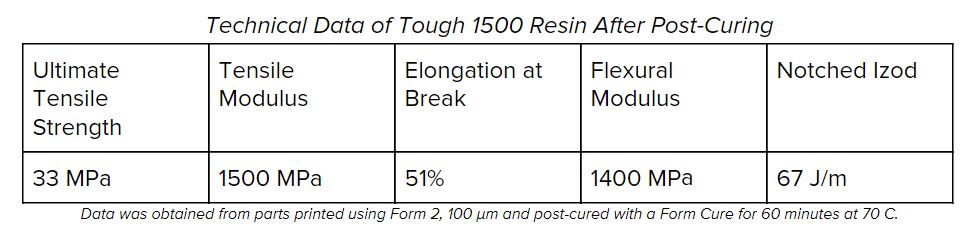

The “1500” in the name signifies the material’s tensile modulus in MPa. Formlabs says it is the “most dynamic resin yet”, and was created based on users’ feedback. The aim was to make the material tough enough to withstand significant pressure but resilient enough to give and bounce back.

Tough 1500 was developed for Formlabs’ desktop stereolithography (SLA) 3D printers, including the Form 3 and Form 2. The majority of the resin’s technical properties fall between the tough and durable resin family of the printer manufacturer company.

Additive Manufacturing in the automotive industry

One early user is Hawthorn-based Unplugged Performance, a specialist in upgrading Tesla vehicles. The high impact strength of Formlabs’s new resin enables the safe mounting of the sensors in the car’s bumper, according to the Tesla customizer company.

Prior to deploying 3D printing in the workflow, completing the customization of a Tesla took more than a day for Unplugged Performance, installing new bumpers by removing and bonding its sensor mounts. Since 3D printing the mounts, the company can upgrade three cars a day.

Carbon Performance, a British automotive technology company also uses 3D printing technology for customizing cars, including Teslas. The company has manufactured a selection of 3D printed brake calipers using its new proprietary automated intelligent platform, SK3L370N. These 3D printed brake calipers, designed for the Porsche GT3RS, Ferrari 812, Lotus Elise, and Tesla Model S are stated to be more robust, and environmentally friendly.

Elsewhere, 3D printer OEM 3D Systems and German automotive R&D center TOYOTA Motorsport GmbH (TMG) partnered to develop “first-to-market” additive manufacturing solutions. Using 3D Systems’ additive manufacturing technology, TMG intends to increase the efficiency of its production processes.

Read more about 3D printing in the automotive industry.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. For more content, follow us on Twitter and like us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured Image shows Telsa model 3 modified by Unplugged Performance photo via Unplugged Performance.