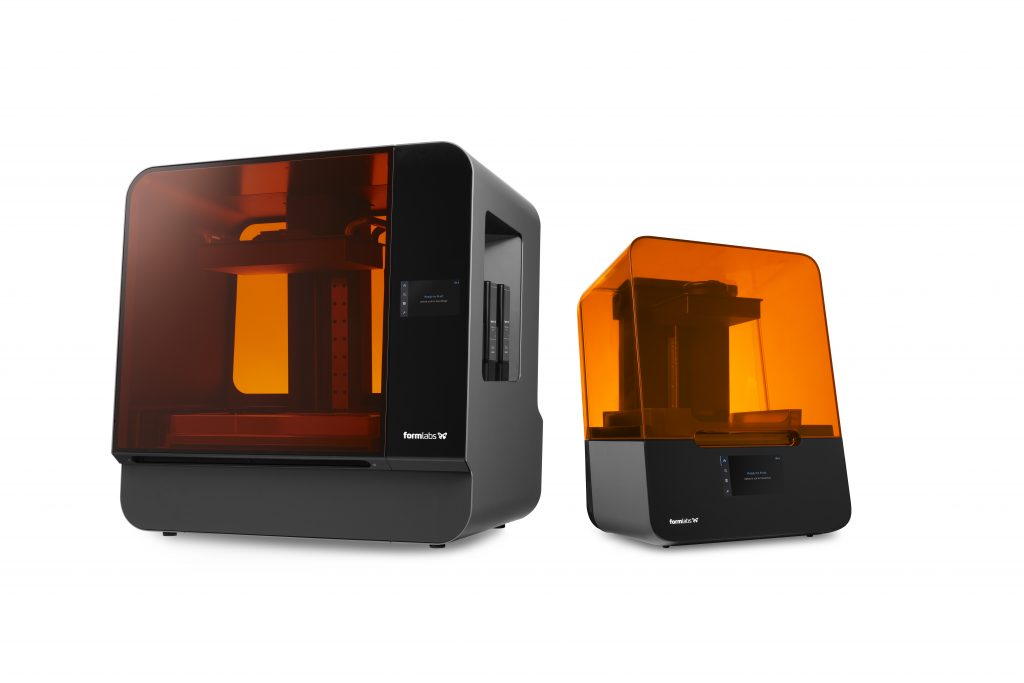

Today, just over three years since the launch of the Form 2, Massachusetts based 3D printer OEM Formlabs announced the forthcoming availability of two new SLA systems: the Form 3 and the Form 3L.

Building on the company’s core expertise, these two systems are powered by a new Low Force Stereolithography (LFS)™ technology, developed to improve the “peel process” in part removal.

Max Lobovsky, CEO and co-founder of Formlabs, comments, “We’ve completely re-engineered our approach to resin 3D printing with the Low Force Stereolithography (LFS) print process behind the Form 3 and Form 3L.”

“We entered the industry seven years ago with the first powerful, affordable desktop SLA 3D printer and since then have shipped more than 50 thousand printers, and our customers have printed more than 40 million parts.”

“Now users are leading the way in how to grow 3D printing from one machine to many, from prototyping tool to game changer.”

Formlabs Low Force Stereolithography

LFS technology in the Form 3 and Form 3L is enabled by a flexible build tank. In place of the standard, rigid tanks, the LFS tank makes it easier to remove a part from the bed after it has been 3D printed. In a procedural sense, LFS technology also provides incredible detail and surface finish, with a uniform, Light Processing Unit (LPU), containing a high density laser.

In the Form 3L, two LPUs are integrated to enable large-format SLA 3D printing, providing twice the laser power, and five times the volume of its little sister the Form 3.

In addition to easy removal from the print bed, Formlabs has worked to make “tear-away light-touch” support removal for 3 and 3L 3D printed parts. Both machines have integrated sensors for improved maintenance – these are linked to send a user alerts about the state of the machine.

Integrated with the Formlabs Dashboard too, 3D printing on the Form 3 and 3L can be activated and managed remotely from anywhere with an internet connection. The systems are also modular and upgrade-able for “constant uptime” and, presumably, future updates.

Large-scale SLA 3D printing and rapid prototyping

The build volume of the Form 3 measures, 14.5 × 14.5 × 18.5 cm (5.7 × 5.7 × 7.3 in), whereas the Form 3L’s build measures, 20 x 33.5 x 30 cm (7.9 x 13.2 x 11.8 in). When asked about the addressable market for a machine of such a scale, a Formlabs spokesperson told 3D Printing Industry that “Form 3L’s size covers +50% of the addressable market.”

In relation to patent protection for LFS technology, the company stated, “Formlabs has a growing patent portfolio and we have continued to invest in that growth with ongoing IP filings.”

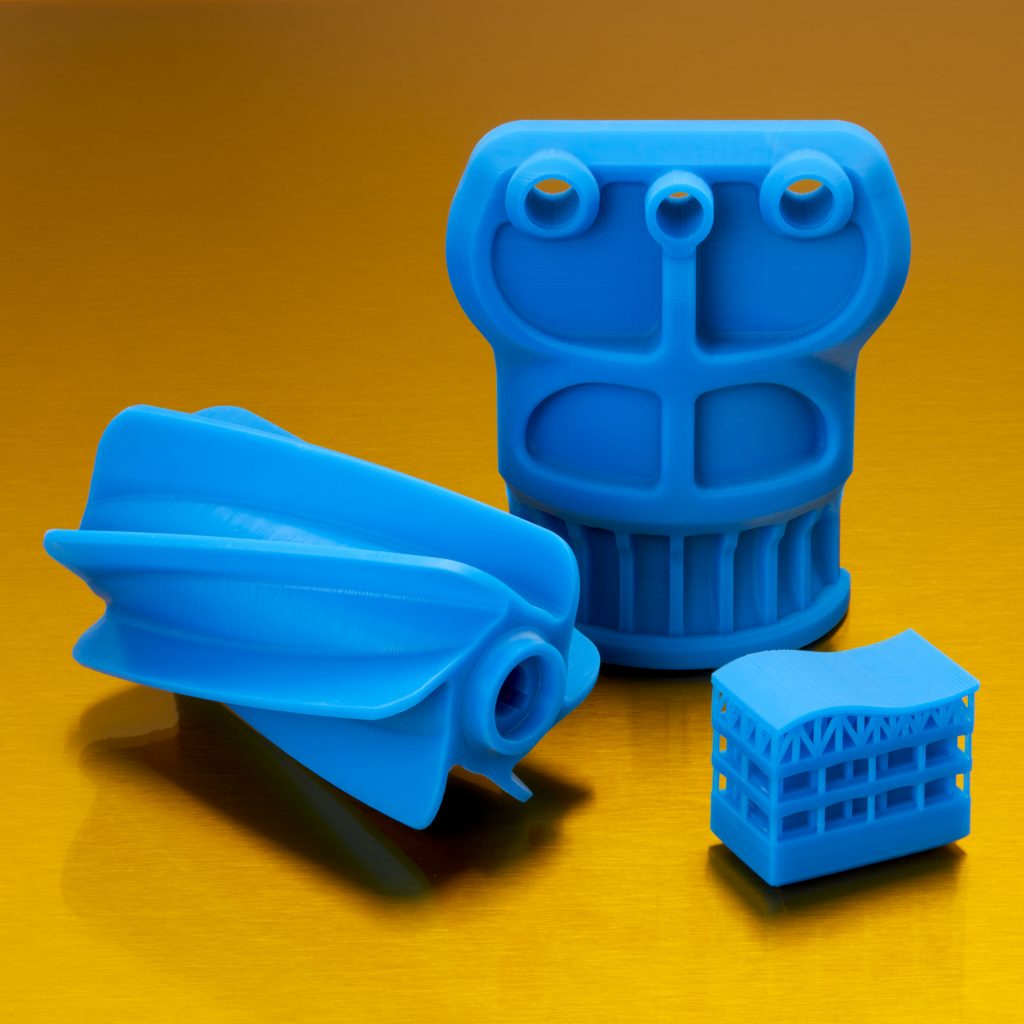

Alongside its new machines Formlabs has announced a new Draft Resin material made for rapid prototyping. Designed 3D print up to 3 to 4 times faster than other standard resins, Formlabs Draft Resin 3D prints layer lines at 300μm, and comes in a striking blue color, to help pick out features.

In an example print job, a model taking up the entire build volume on a Form 2 would, typically, take up to 20 hours to print. In Draft Resin, the same part takes less than six hours to complete.

Form 3 and Form 3L availability and pricing

The first shipments of the Form 3 is expected in June 2019, with Form 3L basic package shipments expected in the fourth quarter of the year. At these points, the systems will be available as part of the following packages:

– Form 3 Basic Package: Form 3 3D Printer, Finish Kit, Build Platform, Resin Tank (F3). Price: $3,499

– Form 3 Complete Package: Form 3 3D Printer, Finish Kit, Build Platform, Resin Tank (F3), Form Wash, Form Cure, Extended Pro Service Plan and Extended Warranty, Resin Cartridge. Price: $5,999

– Form 3L Basic Package: Form 3L 3D Printer, Finish Kit, Build Platform, Resin Tank (F3L). Price: $9,999

In a quick update of the Fuse 1, the desktop SLS 3D printer announced by the company in June 2017, a Formlabs spokesperson said that this would be shipping in 2019.

Concluding the press briefing, Lobovsky comments, “We’re excited to take another huge leap forward with LFS 3D printing, dramatically improving the print quality and reliability people can expect while still offering the most powerful and affordable 3D printer on the market.”

Formlabs is currently exhibiting at AMUG 2019 in Chicago (booth D4) and at Germany’s Hannover Messe (Hall 6, G08). Visitors to these shows can stop by for more information on the new Form 3 and Form 3L.

Formlabs is nominated in the 2019 3D Printing Industry Awards. Vote now to decide this year’s winners.

For all of the latest AMUG 2019 news and other additive manufacturing updates, subscribe to the daily 3D Printing Industry newsletter, follow us on Facebook and like us on Twitter. Seeking new opportunities in the fast paced 3D printing industry? Join 3D Printing Jobs now for current vacancies.

Featured image shows a speaker prototyped on the Form 3L. Photo via Formlabs