California headquartered 3D printer provider Raise3D has announced its new RaiseFactory 3D printing systems at Hannover Messe 2019 this week in Germany. With the new RaiseFactory, Raise3D will be looking to take its first step into Flexible Manufacturing solutions. It is planned for launch in Europe for early October.

The RaiseFactory systems are based on the Pro2 series 3D printers, released by Raise3D in 2018, which have been nominated by our readers in the 2019 3D Printing Industry Awards. Diogo Quental, Raise3D’s general manager for Europe, commented “The major advantage of these systems relies on its flexibility. They are easy to set up, use and maintain, they allow parallel production with multi-materials, and are highly versatile and easily scalable.”

“They can be the best solution for on- demand and small batch production, but also for the transition period we are going through, when corporations need to easily adapt to the on-going technological change.”

Towards Flexible Manufacturing

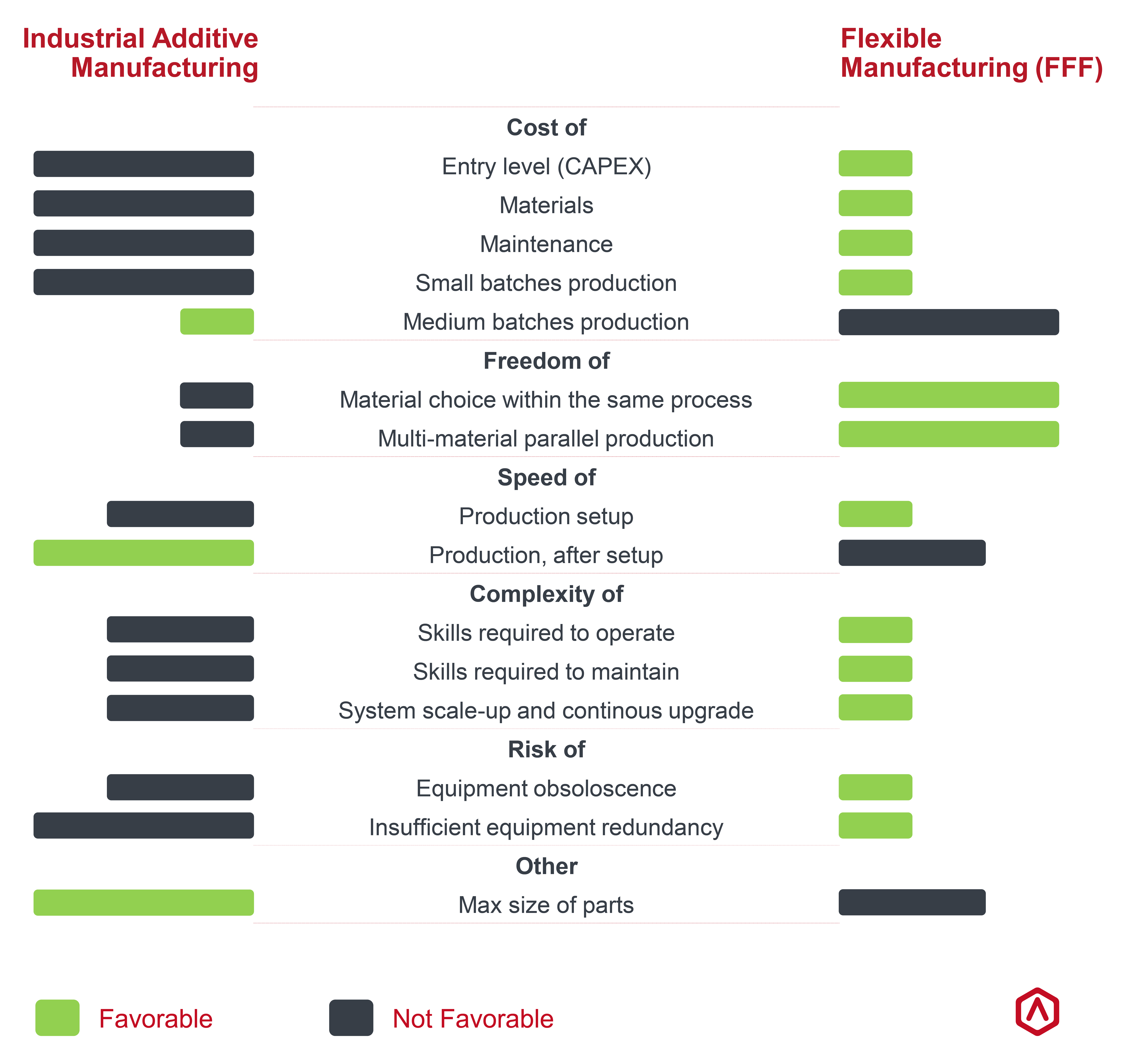

With the Pro2 series FDM 3D printer, Raise3D began a new phase in development towards Flexible Manufacturing. Flexible Manufacturing centers around FDM 3D printing factories that are able to turnover customized product batches reaching several thousand 3D prints, while costing less than $100K to install. Compared to Raise3D’s perspective of Industrial Additive Manufacturing, i.e. 3D printing production that relies on the set up of expensive machines, Flexible Manufacturing offers a number of advantages, as detailed in the chart below.

The main ways Flexible Manufacturing is effective, is in material choice, set-up and upkeep costs, and the simplicity of operation. Where Industrial Additive Manufacturing has the advantage is in the speed of production, cost of large batches and the size of parts that can be products.

Enabling RaiseFactory

The RaiseFactory systems will make use of RaiseCloud print management software to provide a Flexible Manufacturing solution, which aims to build collaboration and pool resources among a network of 3D printing systems. Raise3D recently launched beta access to the software.

Speaking in an interview for 3D Printing Industry, Quental explained, “Digital additive manufacturing, depending on the industry and application, will require different types of solutions. We expect desktop based solutions to represent a substantial share of it as they have some relevant advantages”

“[…] Our strategic approach is to prepare Raise3D to be a top contributor in this transition, by offering the right solution in each stage of the market development.”

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the RaiseFactory systems. Image via Raise3D.