British automotive technology company Carbon Performance has manufactured a selection of 3D printed brake calipers using its new proprietary automated intelligent platform, SK3L370N.

The SK3L370N platform automatically generates environmentally sustainable designs for 3D printed automotive parts using self-taught algorithms. According to Gilbert Peters, CTO of Carbon Performance, “Carbon Performance is truly democratizing the automotive industry making it accessible for automakers of all sizes from giants to independent start -up teams to develop the cars of tomorrow,”

“I believe that it is the ripe time that the potential of additive manufacturing and digitalization is realized in the automotive and the wider transportation industry.”

The SK3L370N platform

Less than five years old, Carbon Performance develops bespoke car parts using deep learning and metal additive manufacturing. It’s previous products have included the fabrication of a 3D printed suspension upright for the Lotus Elise sportscar. As a result of its collaboration with standards organization SAE International, the company also produces parts for the Formula SAE and Baja SAE student racing competitions.

“The face of Mobility is changing rapidly with electric cars growing at 59% and autonomous cars growing at 37%,” states Carbon Performance, “but in order to accelerate the move towards sustainable transportation, more companies, especially SMEs and start-ups need to start developing and building the cars of tomorrow.”

To give smaller manufacturers access to the automotive industry, the SK3L370N one-stop, cloud-based ecosystem was introduced. The platform facilitates the digital development of complete cars and individual parts, and aims to eliminate prohibitive costs, human capital, resources, time, and infrastructure requirements.

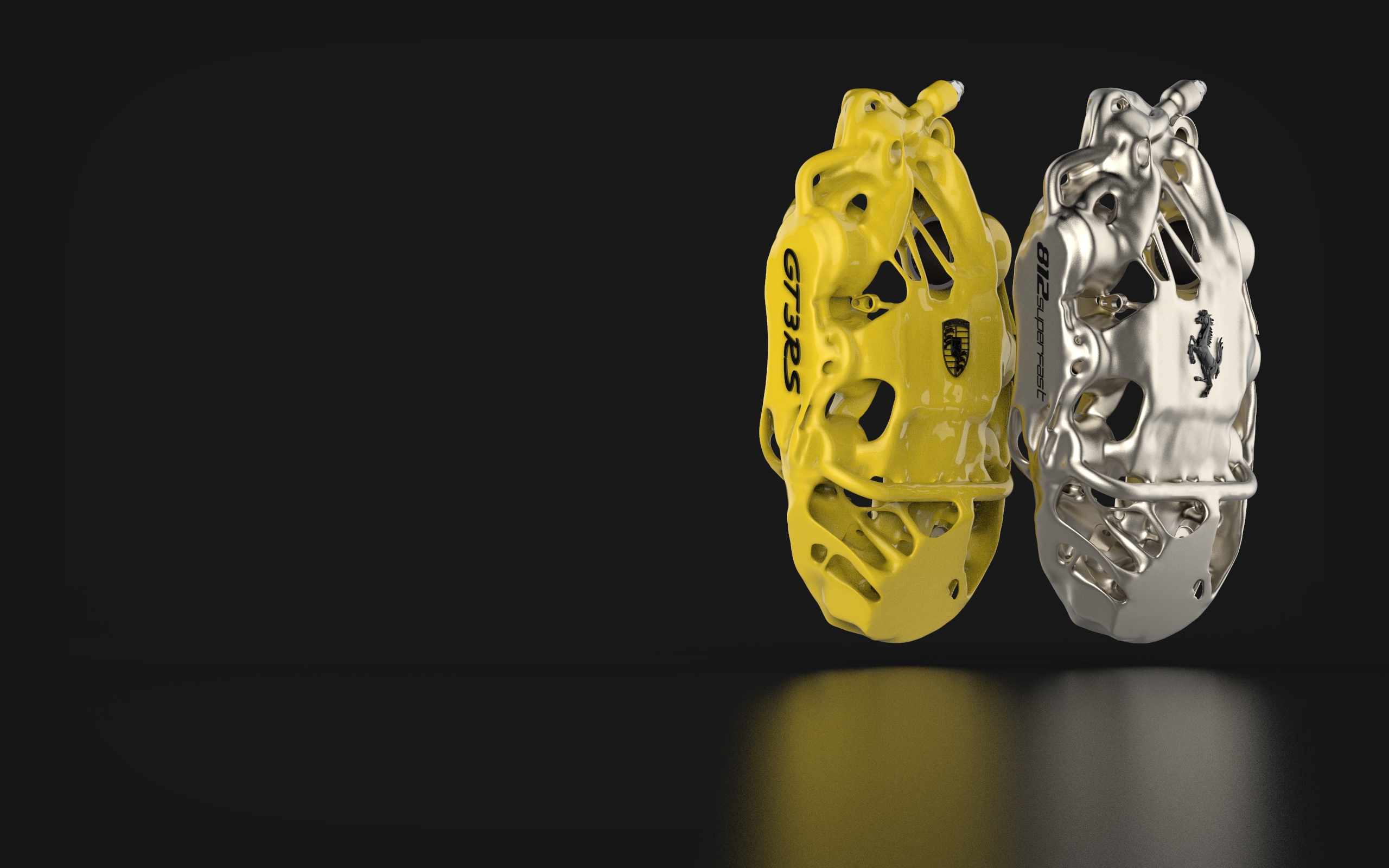

3D printed brake calipers

Brake calipers are used to slow the wheels of a car using friction with the brake rotors. As a highly complex part, with room for performance improvements, the parts have previously been redesigned for additive manufacturing by Bugatti. At Carbon Performance, one of the main reasons for redesigning brake calibers for additive manufacturing is the potential to improve the product’s sustainability, which comfortably aligns with the company’s involvement in Autodesk’s Future of British Manufacturing, and the British government’s Northern Powerhouse initiative.

In comparison to their traditionally made counterparts, Carbon Performance’s SK3L370N generated 3D printed brake calipers are said to be more robust, and environmentally friendly thanks to, in part, their ultra-lighteweightedness. The calipers have been variously designed for the Porsche GT3RS, Ferrari 812, Lotus Elise, and Tesla Model S.

Taking the concept further, in early 2020 Carbon Performance is planning to launch an entirely 3D printed electric autonomous car platform using SK3L370N.

For more automotive additive manufacturing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Also, join 3D Printing Jobs now for new opportunities in engineering.

Featured image shows a 3D printed brake caliper created on the SK3L370N platform. Image via Carbon Performance.