One company in Bavaria is helping women who have had breast surgery through the customization possibilities offered by 3D printing. Lingerie company Anita has employed their German RepRap X400 to streamline the making of breast prostheses. 3D printing has saved about 50% of their cost to make these specialized products.

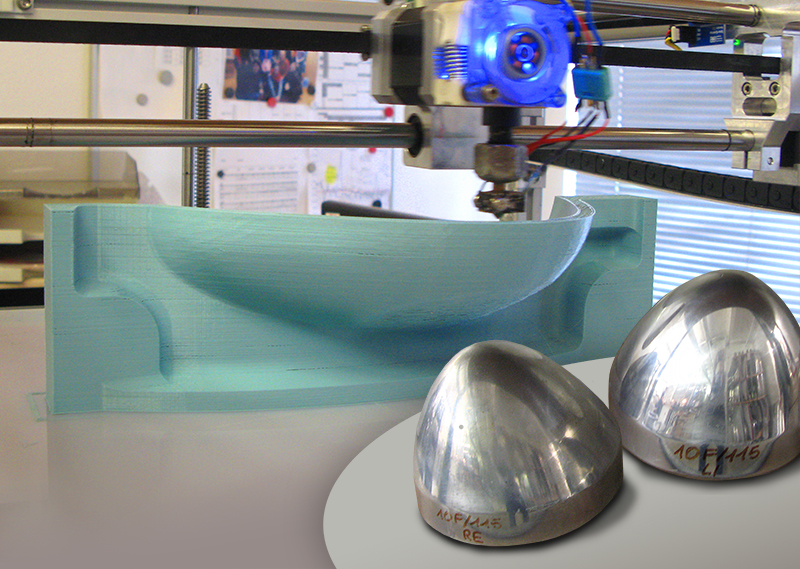

Due to nearly infinite variety of breast shapes and sizes, Anita must make forms for hundreds of different prostheses. Traditionally, the process began with a wooden template, which was used to make a fiberglass prototype. Then, a 14-day process ensued to mirror the fiberglass shape, and turn it into an aluminum mold for pouring silicone. Now, Anita simply scans existing molds to mirror and stitch together in CAD. Slicer software, then, dissects the CAD file into G-code for use by the X400. Within hours, a positive PLA model is printed. This model is cast in sand with molten aluminum and a useable mold is born. The reduced cost is due to the speed of this procedure, and lack of milling needed to finish the tool.

Partial and full mastectomies can lead to asymmetry, postural imbalance, and fractured confidence. Anita is working to restore the confidence of women who do not want to be defined by an illness, nor its physical effects. By reducing manufacturing costs for these prostheses via 3D printing, Anita could pass the savings onto their customers. Then many women would find it that much easier to be themselves.