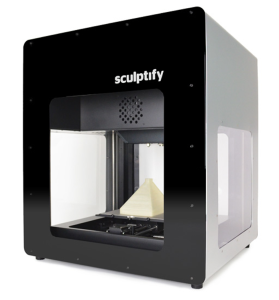

For some time now, 3D printer startup Sculptify has been slowly teasing the release of their pellet-crunching 3D printer, David. In fact, until last month, we didn’t even know his name was David. Now, ahead of an August Kickstarter campaign, the coy 3D printer has finally revealed himself, specs and all.

David is unique among desktop 3D printers in that, instead of spools of plastic filament, he eats plastic granules using Sculptify’s Fused Layer Extrusion (FLEX) technology. This has the potential to cut costs and lead to purer printing materials as, normally, spools of filament are derived from pellets in the first place.

The company also believes that the ability to process pellets directly will lead to a wider range of printing materials, many of which the company is already planning to sell, including: ABS, PLA, and Nylon, some of the standard 3D printing materials; high-density polyethylene, found in milk jugs and plastic bags; ethylene vinyl acetate, a soft silicone-like material used in sportswear; thermoplastic polyurethane, the rubbery stuff you find in shoes and phone cases; high impact polystyrene, the material disposable forks are made of; polycarbonate, which is used to make safety glasses; and wood composites.

We’ve received a comment on a previous article about David as to the financial backing of Sculptify. With sleek marketing and what looks like a working prototype, the commenter suggested that the company had no need for crowdfunding, but Sculptify’s CEO, Slade Simpson, remarked in the firm’s latest press release, “We have gone as far as we can with our personal savings and loans from family members — it’s time for us to get out of our basements and get this product into the community’s hands. Their support and input will expedite the material optimization process, and help make David the most capable 3D printer possible.”

Altogether, David seems like a great guy. I’m most excited about the material possibilities. The mention of polyethylene and polystyrene imply that David will do his part for the environment by recycling your old milk jugs and disposable forks. I don’t want to jump to any conclusions, but I wonder if Sculptify has some sort of processing device in the works, as well. If not, they’d better get on it, as I bet eco-minded consumers will want to use David as a home-recycling unit. We’ll just have wait until August to know for sure.

Update: Sculptify’s CEO, Slade Simpson, has since commented on the ecological impact that David might have:

We have done a few trials of recycling parts in-house, and for all intents and purposes, it’s completely feasible. Since most (if not all) of the materials that David will ever print will be thermoplastic polymers, they can be printed and reprinted over and over, with the only limit being the degradation of the material. In theory, you could print a part, use it for a while, then grind it, and reprint it. This could potentially go far beyond David just printing recycled materials (like the new 3D Systems machine) – he could, practically speaking, reuse the same material over and over, until contamination/degradation becomes an issue – let’s see Will.I.Am do that.

[We] haven’t developed a regrind attachment or recyclifyer, yet. That being said, it’s something that we have heavily considered, as it would be simple to do. Kickstarter funding will obviously help us expedite the development process of said machine, if there is community demand for it. I personally think it would be amazing to have an attachment (or separate device) like this – it could help us reach countries with limited resources, and also help lead the 3DP sector down a less wasteful path.

Even without an attachment, David is still kinder to the Earth than other printers, in terms of printing medium. Generally, the more processes you can remove from something, the better it is for the environment (in the product sector, anyway). Since we are eliminating several steps in the filament creation process, I think that we could safely argue that David has the smallest virtual carbon footprint of any printer. Our power requirements obviously come into play here, but I’m speaking strictly in the sense of materials.

In other words, no recyclifyer, yet, but it’s not completely out of the question!