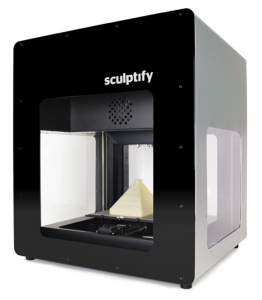

A month back, we reported on a company with plans to release a desktop 3D printer capable of printing directly from pellet feedstock, skipping the filament middleman seen with FDM/FFF 3D printing. The benefits of Sculptify’s Fused Layer EXtrusion (FLEX) process, include a decrease in cost and an increase in the variety of materials the printer is capable of handling, thanks to the elimination of the need for filament. Sculptify has finally released their machine to the public and his name is David. Everyone, this is David. David, Everyone.

Why name the 3D printer David and not FLEXbot or the 3D FLEXer or some other less original name? Simpson explains, “We came up with the name David after being inspired by the famous sculpture created by Michelangelo. It’s one of the most recognized works of art in the world, and reminds us that with the right tools, anything is possible. We have poured our hearts and souls into this printer for the past year and a half, and we are really excited to get it into people’s hands.”

If David is as capable as his creators claim, he’ll be able to FLEX a wide variety of pelletized materials for consumer and commercial users alike. The company’s Director of Business Development, Luke Daniel, says, “David provides customers with the freedom to choose from an extensive selection of materials — which range from hard and durable to soft and flexible. By eliminating the dependence on filament, Sculptify can offer exotic materials and composites never before used in 3D printing.” Sculptify also suggests that, because mass produced products usually begin in pellet form, pellets are less processed and cost less than other feedstocks.

David sounds like a great fella, but when will his fans get to meet him in person? Sculptify plans to debut David on Kickstarter in the near future, at which point, backers will be able to order the 3D printer in exchange for funding the project.

Aside from more detailed specs (build size, layer thickness, speed, etc.), this all leaves me with one final question: Is he single?

Source: Sculptify