When it comes to energy, finding a sustainable clean energy alternative to fossil fuels is one of the most talked about engineering challenges. Wind power is a very popular alternative due to its lack of emissions, and it can be applied to virtually any environment. While we’re working to develop mass-scale clean power solutions, it’s often forgotten that there are still many communities that don’t have any access to power.

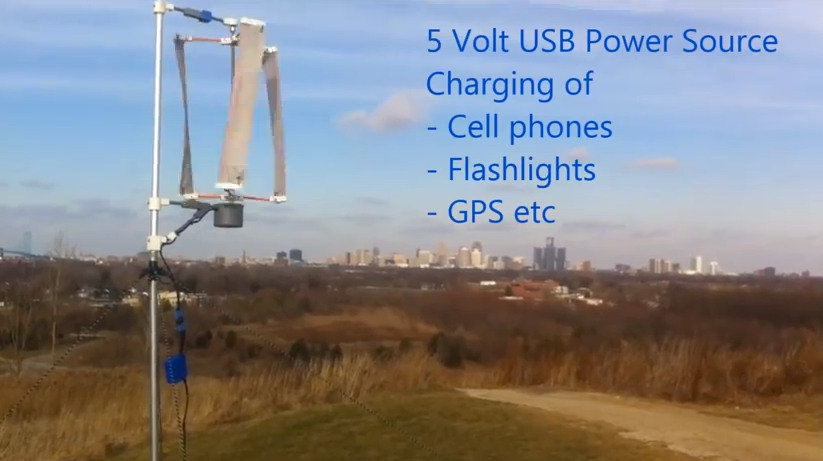

The David McFadden Energy Entrepreneur Challenge, a yearly energy challenge organized by the Ontario Centers of Excellence, is working to help bring power to everybody. The theme of this year’s challenge is “Meeting the Energy Challenge of Remote Communities”. Kyle Bassett, a PhD candidate from the University of Windsor, believes he’s come up with a solution to get power to those communities in an affordable and time-efficient manner. He’s designed a compact wind turbine constructed of 3D printed parts, with a few added materials, that can be assembled and installed anywhere in as little as two minutes. The turbine features a foldable rotor and tower, so it can easily collapse into the compact size of 100cm x 10cm. This helps lower shipping costs, and makes it easy for transport to remote locations.

The turbine outputs 5V to any USB-powered device. This will allow people to charge flashlights, cellphones, GPS, etc. In the future, he hopes to connect multiple turbines in series to achieve greater power output, and, thus, have even more value for the community. In order to account for all weather conditions, Basset has included the ability to charge a lithium polymer battery while the turbine is in motion. If it’s a still day with no wind, there’s no problem!

Kyle personally knows how having access to power can make a huge impact in people’s lives. After obtaining his Masters degree, Bassett spent eighteen months working in rural Venecia, Nicaragua. Upon arrival, they had no access to power, so he took it upon himself to come up with a reliable solution. He fabricated multiple turbines, similar in design to his current turbine, and connected them to form a community power station. The clean power source was an instant hit, and people began to journey from miles away to charge their flashlights and cellphones.

Compared to the massive wind turbines most people are used to, it’s amazing what a huge difference this small turbine can make. This project is truly helping to get renewable energy technology to the people who need it most. Finalists for the McFadden Challenge will be announced in March, and Bassett is planning to launch a Kickstarter campaign in Spring 2015. Be sure to follow the project’s website for updates!