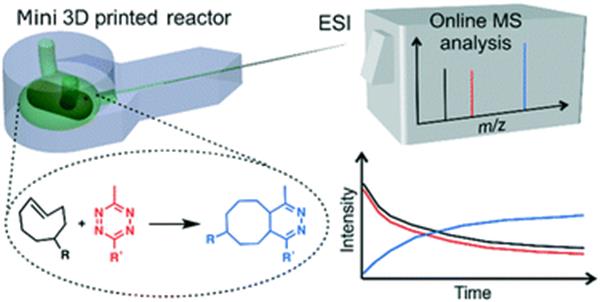

Researchers at the University of Helsinki have demonstrated how 3D printing can save both time and money. A team led by Dr. Gianmario Scotti 3D printed disposable microreactors and the research, plus STL files, is now available online.

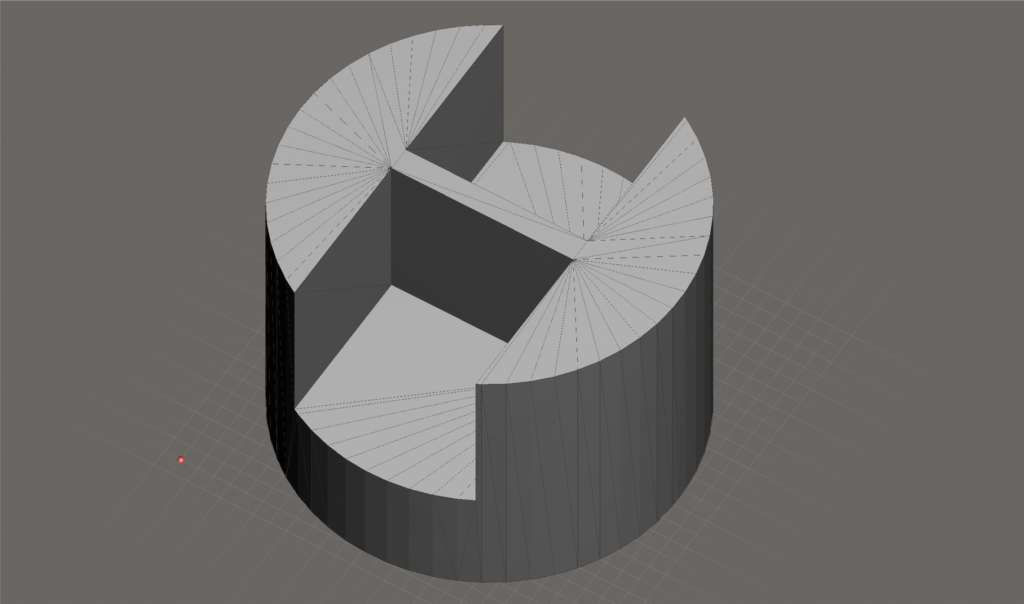

In the academic paper the scientists describe how, “A stainless steel nanoelectrospray ionisation capillary and a magnetic stir bar were integrated into the reactor during the printing process.”

The resulting integrated nanoelectrospray ionisation capillary,

Allows direct sampling of a reaction solution without external pumping. It also allows ionisation of the analytes. Therefore, very rapid online mass spectrometric chemical reaction monitoring is possible. Operation of the miniaturised reactor is shown by the online nanoelectrospray mass spectrometry characterisation of a Diels–Alder reaction and the subsequent retro Diels–Alder reaction.

As 3D Printing Industry has frequently reported, creating 3D printed tools for research is a particular advantage that many in the scientific community are using to advance knowledge in many areas.

3D printing creates a more efficient workflow

The purpose of this particular project was to create a more efficient workflow, this should in turn allow for a higher volume of experiments to conducted. Prior to the creation of the 3D printable microreactor, Dr. Scotti had to travel 15 km from his research lab to a cleanroom facility.

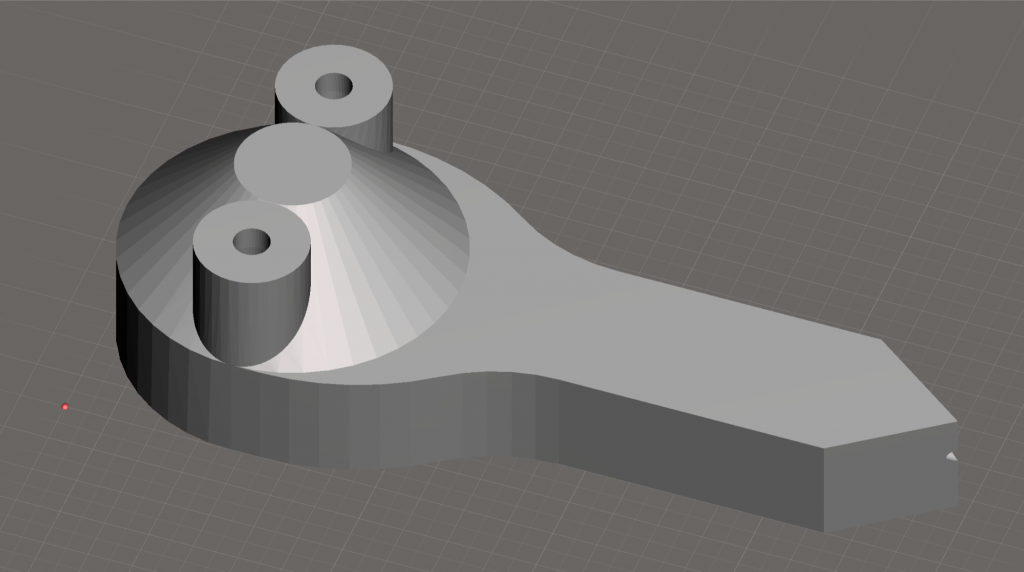

Together with fellow scientist, Markus Haapala, Dr. Scotti hit upon the idea of using 3D printing to build small, disposable containers that would circumvent the need to use the cleanroom. The resulting 3D printable vessels are used to house the chemical reactions that are the focus of Dr. Scotti’s research.

Fellow researcher, Sofia Nilsson explains how “by hooking up a microreactor to a mass spectrometer, reactions can be followed in real time with high sensitivity and selectivity.”

Studying transition states of reactions

Once the reaction vessels were designed the researchers constructed them from polypropylene. The material was selected for its strength, durability and the fact that it would not interfere with the reaction under observation.

Nilsson explains the benefits of 3D printing the microreactors, “Thanks to this, it’s possible to detect intermediates and even transition states of reactions, making the stipulation of a reaction mechanism possible, which is what my research is focused on.”

Gianmario Scotti, Sofia M. E. Nilsson, Markus Haapala, Päivi Pöhö, Gustav Boije af Gennäs, Jari Yli-Kauhaluoma and Tapio Kotiaho are the authors of the study.

The research paper, A miniaturised 3D printed polypropylene reactor for online reaction analysis by mass spectrometry, is published in the academic journal Reaction Chemistry & Engineering and can be accessed here.

For all the latest 3D printing news, subscribe to our free newsletter here and follow our active social media accounts.

Also, don’t forget that 3D Printing Industry readers can vote now in the 1st Annual 3D Printing Industry Awards.

Featured image shows the main building of the University of Helsinki.