We often take it for granted that 3D printing will change manufacturing by making many products more customizable. In the end, though, which are the products that are leading this revolution today? Shoes are fascinating but not yet fully ready-to-wear, jewellery is exploring many new possibilities but truly personalized jewellery still has a bit of a way to go, especially on FDM/FFF systems. The one product that might fully exploit the personal fabrication possibilities offered by desktop 3D printing might be sunglasses.

Soda Concept is a startup founded by Carlo Marchisio, a young italian designer. Italy is currently home to the biggest sunglasses manufacturer in the world, the Luxottica Group owning both Ray Ban and Oakley, so it would just make sense that next generation of (3D printed) sunglasses would come from here.

“It all started when I bought a MakerBot Replicator last January – says Marchisio – I knew how to 3D model but was not yet familiar with giving a physical shape to my models. As soon as I got the hang of it I tried to find an end-use product that I could make with my MakerBot Replicator, something beyond prototypes and toys, something useful that could be used every day”.

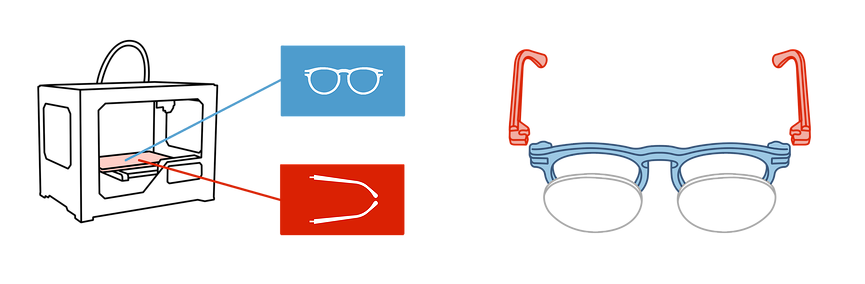

In the end, given the availability of ABS and PLA materials and the plate size, Marchisio settled on sunglasses. He pushed the limits of his MakerBot to come up with four different highly customizable frames, with interchangeable lenses and arms.

“I created four types of frames with arms and lenses that can simply snap on, without requiring the use of any metal component. This allows users to change the farm colour, replace any broken part easily and even move on to a new, more fashionable, frame design without having to buy new lenses, which are likely to be the most expensive item”.

Marchisio named his project “Soda” because it is an international word that everyone can understand and that conveys a sense of pop culture and ease. In a way, changing sunglasses will be as easy as drinking one of those small glass Coca Cola bottles on a hot day at the beach.

The project’s international aspects are also evident. While being designed in Italy, Soda Concept glasses and components are currently sold though RedResin, an English language, Barcelona-based 3D printing consumables (filaments and resins) e-tailer. Working with RedResin allowed Marchisio to experiment with future iterations of his models.

“We were able to print out multi-material frames on an Objet Connex system and we experimented with a desktop Form1 too,” reveals Marchisio. “The time is not ripe yet, as SL technology is most efficient when producing small and highly intricate objects, however there is no doubt that the smoothness and quality of the output will come in handy in the near future.”

Material experimentation is not limited to resins. Marchisio has also been using ProtoPasta’s carbon fiber reinforced filament and now intends to try out the new MakerBot photochromatic PLA. He is also working on an augmented reality app that will let potential customers try on the different frames and colours before purchasing them.

The business has been growing. In the beginning glasses were sold through a few local stores in Turin, Marchisio’s home city, and now he is able to address a global audience. Future developments may even include the possibility of selling designs for people to print at home. “Most users need to familiarize themselves more with 3D printing to be able to create a high quality product at home. It will happen but what we need to continue doing is helping the 3D printing culture spread”. One great way to do it is by making it fashionable.