Register now for our Additive Manufacturing Advantage online event for insights on AM developments in aerospace, space, and defense sectors from industry leaders!

Belgian 3D printing services and software company Materialise announced significant development at RAPID + TCT 2024, to improve the design-to-manufacturing process.

At the event, Materialise unveiled the latest version of Magics, its flagship software for data and build preparation. The new Magics 28 features a Lattice Module supporting beam lattices for creating intricate designs with lighter data sets, promising faster file processing. Alongside Magics 28, Materialise also announced partnerships with Ansys, nTop, and EOS to further improve its additive manufacturing capabilities.

“As additive manufacturing evolves towards new applications and serial production, Materialise is dedicated to enhancing our offerings and forging collaborations that best serve the needs of our users and customers,” said Bryan Crutchfield, Vice President and General Manager of Materialise North America. “Our efforts aim to advance the industry by tackling challenges in quality and workflow efficiency.”

Software innovations by Materialise

To enhance file processing speed and accuracy, the latest version introduces a new Lattice Module supporting beam lattices for creating complex designs with lighter data sets. It also includes an improved Nester Module for automatic part placement on build platforms, optimizing part distribution, reducing material usage, and enhancing part protection with customized packaging. Based on customer feedback, the user interface has been updated offering a dark theme option to reduce visual strain during extended software use.

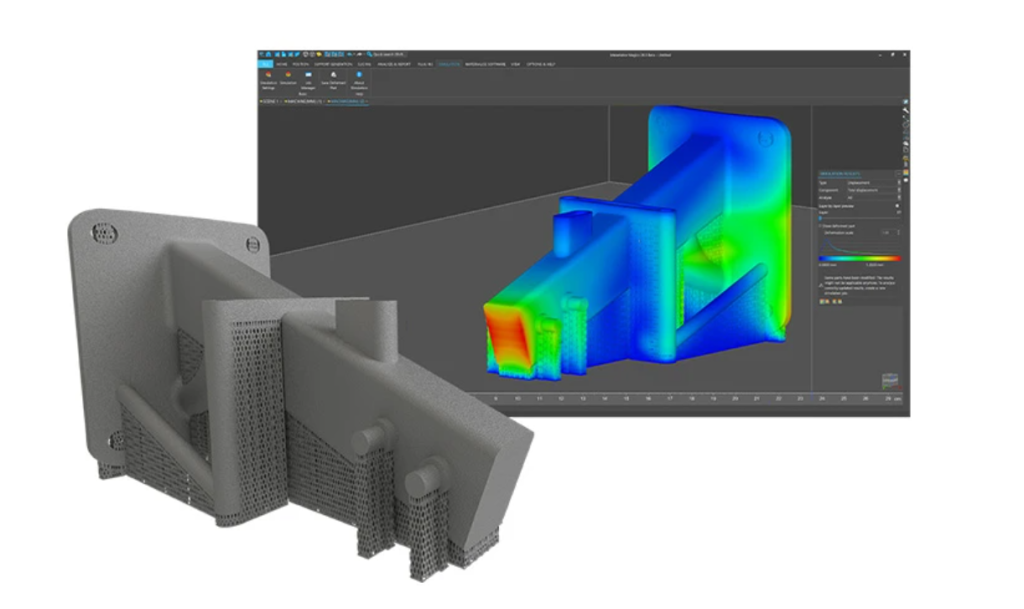

Additionally, the previous version of Magics now integrates with Ansys’ simulation software for laser powder bed fusion (LBPF) metal 3D printing, allowing users to identify design weaknesses and support issues before printing. This integration aims to improve build success rates, minimize scrap, and save time and materials in the printing process.

Materialise and nTop announced a collaboration to streamline the design-to-manufacturing process, enabling the production of previously unprintable complex parts. By integrating nTop Core’s implicit modeling API with Materialise’s Magics 3D Print Suite and NxG Build Processor, the companies aim to facilitate a seamless exchange of design files, eliminating intermediate steps like meshing.

According to the company, this integration minimizes file sizes and enhances the efficiency of preparing and slicing high-performance designs, addressing challenges associated with processing larger, intricate parts. The collaboration aims to streamline workflows in 3D printing, potentially advancing industry practices.

At this year’s AMUG conference, Materialise unveiled e-Stage for Metal+ software, a solution tailored for LPBF systems. This software employs physics-based modeling to automate support structure generation, aiming to streamline metal AM and reduce associated costs and complexities.

By predicting and optimizing support placement for enhanced stability and heat distribution, it promises to minimize post-processing requirements. Integrated within Materialise’s Magics platform, it offers compatibility across various 3D printing technologies, facilitating improved workflow efficiency and accessibility in the AM sector.

Promoting metal AM adoption

Materialise also highlighted its continued alliance with EOS to enhance quality control for metal 3D printed parts in the aerospace and medical industries. By integrating multiple EOS process data sources such as optical tomography and powder bed camera data with Materialise’s Quality & Process Control (QPC) system, the companies enable comprehensive inspection of additive manufacturing (AM) processes to identify anomalies.

This collaboration reduces the need for costly post-manufacturing quality reviews. As a member of the EOS Developer Network (EDN), Materialise can leverage open APIs to seamlessly import EOS-generated optical tomography data into their QPC system. Integrated within Materialise’s CO-AM Software Platform, QPC supports manufacturers in planning, managing, and optimizing 3D printing workflows from planning through to quality inspection and post-processing.

In April 2024, Materialise and Renishaw announced a strategic partnership to boost efficiency and productivity for users of Renishaw’s systems. This collaboration involves integrating Materialise’s specialized build processor software and Magics software with Renishaw’s RenAM 500 series.

The goal is to streamline workflows, offer better control over the AM processes, and reduce production timelines. By leveraging advanced tools for handling complex geometries and optimizing part production with customizable print parameters, the partnership supports the broader adoption of metal AM across diverse manufacturing applications.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows the Materialise booth at RAPID + TCT 2024. Photo by 3D Printing Industry.