Voting closes today in the 3D Printing Industry Awards 2023. Have your say now!

Nikon SLM Solutions and Materialise have partnered to advance the Materialise Build Processors (BPs) tailored for Nikon SLM Solutions 3D printers.

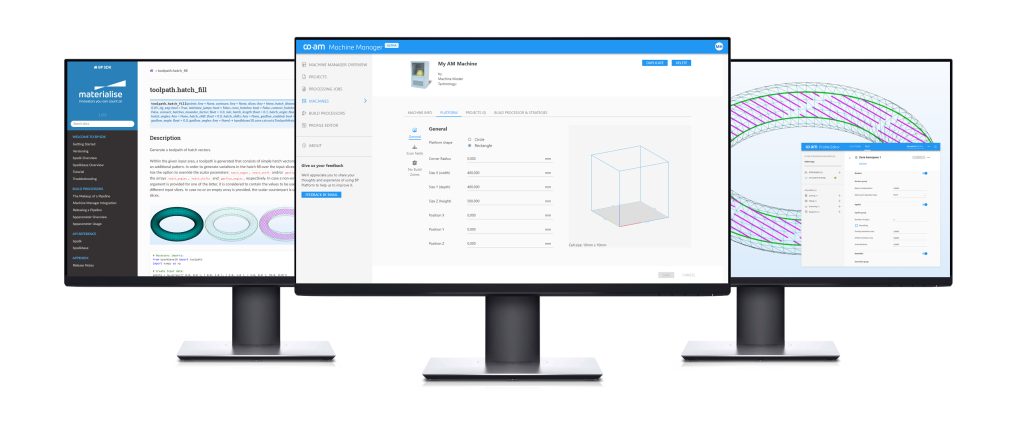

As end-use components increasingly utilize metal additive manufacturing, there is a growing demand for enhanced part quality, competitive pricing, and faster production processes. This collaboration is designed to integrate Nikon SLM Solutions NXG printers seamlessly into the Materialise CO-AM platform. In doing so, manufacturers can access improved capabilities for metal additive manufacturing (AM) of end-use components.

“Nikon SLM Solutions and Materialise share a vision of open systems that enable AM users to make optimal use of their equipment and connect it to their preferred solutions,” says Bart Van der Schueren, CTO of Materialise. “We look forward to offering the next generation of BPs to Nikon SLM Solutions users and providing them access to software solutions covering the whole AM workflow.”

Next-gen build processors to enhance productivity and flexibility

Nikon SLM Solutions and Materialise are collaborating on next-gen Build Processors (BPs) to streamline data preparation, addressing the bottleneck of extensive data volume. Slated for a release soon, the Materialise BPs will be compatible with NXG machines and all SLM users using Materialise software. Acting as a vital conduit between 3D printers and data preparation software, Build Processors play a crucial role in transferring the information required for 3D printers to create parts. The Materialise BPs, crafted with the Materialise BP Software Development Kit (SDK), enable users in the AM field to personalize process parameters, thereby optimizing application outcomes. By employing the Materialise BP SDK, this collaboration offers machine manufacturers a pathway to protect their intellectual property (IP).

Nicolas Lemaire, Product Manager of Software, Product Control, and Strategic Partnerships at Nikon SLM Solutions, explained, “Working with Materialise, we have made a giant leap in developing a high-performative Build Processor. With this next generation of Build Processors, our customers using Materialise software will save time during the print job setup and profit from tools to optimize their print process.”

The collaboration enables direct machine connectivity via SLM.Link to Materialise CO-AM, streamlining AM workflows from order to delivery. Users can access diverse solutions from Materialise and third parties within CO-AM, supporting design automation, mass customization, labeling, and post-processing. This platform allows the management of technologies from different builders. Anticipated with Materialise BPs is heightened connectivity, enabling Nikon SLM Solutions users for more adaptable 3D printing optimization, including various processes.

Alliances as a pillar for metal 3D printing advancements

Powder bed fusion 3D printer manufacturer Xact Metal and System Create Co. partnered to broaden access to cost-effective metal 3D printing for small and medium-sized enterprises in Japan. Xact Metal’s CEO, Juan Mario Gomez, cites that the company aims to combine essential metal additive manufacturing specs with breakthrough technology, breaking down financial barriers. System Create Co., backed by three decades of 3D printing experience, will provide technical support for Xact Metal printers, supporting its mission of enabling widespread adoption of affordable metal 3D technology in Japan.

Oerlikon’s subsidiary Oerlikon AM and US 3D printer manufacturer 3D Systems announced a partnership to scale metal additive manufacturing. This partnership leverages 3D Systems’ Direct Metal 3D printing and Oerlikon AM’s surface engineering, aiming to fast-track market entry for applications in semiconductors and aerospace. Oerlikon AM acquired its fourth 3D Systems DMP Factory 500 3D printer, aiming to improve to innovation and precision in metal additive manufacturing for demanding industries.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Materialise and Nikon SLM Solutions partnership banner. Photo via Materialise.