In the center of Buenos Aires, there is a huge, beautiful park – about as large as Central Park in Manhattan – that is entirely covered by free wi-fi. All you have to do to use it is connect and click on “I agree with terms”. Central Park, Hyde Park in London, and Parco Sempione in my home city of Milan are not covered or only partially covered by wi-fi. Oftentimes, the registration and connection process is lengthy and complicated. The wi-fi in this park in Bueonos Aires is an example of technological leapfrogging, which is the reason why, for example, Kenya has the highest number of mobile phones per person in the World.

INTI, the National Insritute of Industrial Technology, is how Argentina aims to leapfrog manufacturing technology through 3D printing. For a nation this large, Argentina does not currently have a widespread manufacturing industry. Other South American countries such as Brazil and Chile are more advanced on this front. However, Argentina does have a high level of creativity and a blooming low-cost 3D printing industry. Uniting them with the research being conducted at INTI on materials, mechanics, micro/nano-electronics and industrial product design, the Argentinian governments now want to establish a widespread technological knowledge base for advanced industrial 3D printing processes as well.

With respect to this, the import limitations wanted by the Kirchner government have somewhat facilitated the growth of 3D printing by playing right into the concept of distributed manufacturing (if you cannot import, then you have to produce locally). The price ratio between 3D printing a part on location or importing it was immediately favorable to 3D printing, even for products that didn’t have the same price ratio in other parts of the world.

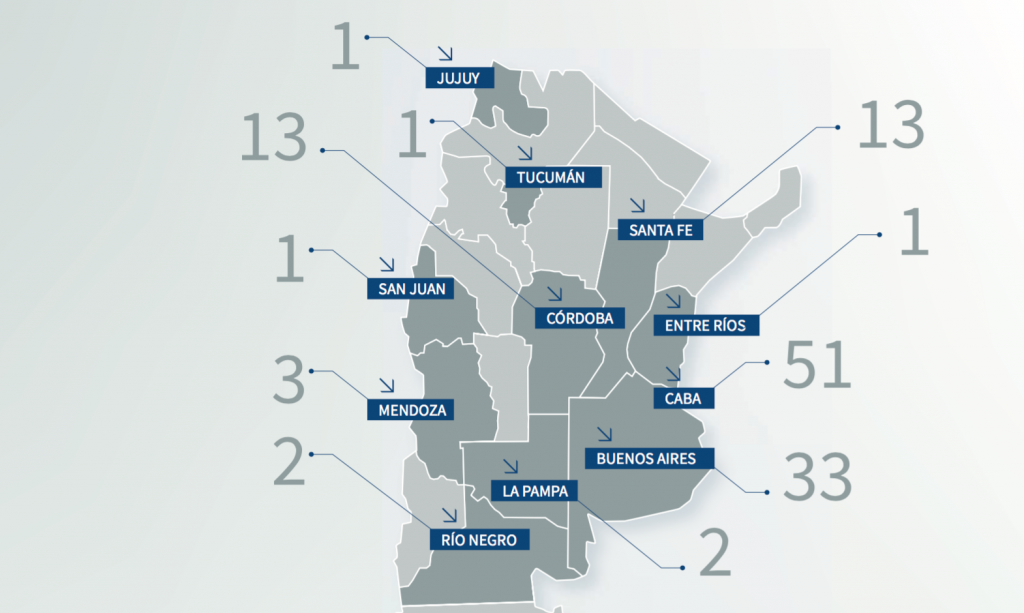

In order to fuel the organic growth of 3D printing in Argentina, INTI has been carrying out several educational, research and organizational projects. While Argentina may not be a large industrial manufacturing country, it is rich with designers and creative ideas. Thus INTI’s activities span across several decentralized R&D centers that work together as a project demands. One is the department of Diseño Industrial, in the Laboratorio de Materializacion. The lab works on several projects aiming to raise nationwide awareness around the possibilities offered by 3D printing. One is the Mapa de i3D, which accurately maps the commercial services and institutions that carry out 3D printing activities throughout Argentina.

Another is by developing educational programs. This includes the publishing of a document, Panorama de la i3D, describing the possibilities offered by 3D printing in several fields of application, including medical, dental and product development. The activities also include the development of an educational program, in partnership with local desktop 3D printer manufacturer Kikai Labs, to create open source, complex product models (such as the rubber band car below) that can be used to teach the younger generations about how to use 3D printing in their projects.

The most significant investment carried out in the department of Diseño Industrial is the recent purchase of a Stratasys Objet 500 Connex 3, multi-material 3D printer. This enables researchers to accurately study the complexities of multi-material 3D printing and to share this knowledge with entrepreneurs interested in investing in this filed.

Another primary area of interest for INTI has been identified in material science. The Plastics R&D Center’s chemical and mechanical laboratories have access to a vast range of machines that can be used to collect data on a wide range of materials. It is also actively working on several spin-off projects focusing on sustainability. One, in partnership with Enyetech, surrounds the development of the world’s first PET filament entirely produced from post-use bottles.

The complex processes necessary to recycle used bottles and other plastic waste in order to produce high quality plastic for 3D printing were fine tuned here at the Centro de Investigación y Desarrollo para la Industria Plastica. They were then used in combination with 3D printing to develop a sustainable business that is also highly beneficial for the environment. In fact, many of the projects being carried out at INTI that focus on materials are very much based on sustainability. Another example is the PHBottle project, in partnership with UE, which aims to create recycled cellulose packaging directly from fruit by-products and materials in wastewater.

Further studies on 3D printing take place in the mechanical engineering R&D Centers, where researchers work on a self-built delta robot on optimizing the process. In line with the Open Source Lab philosophy described by Professor Pearce at Michigan Tech, they also use the 3D printer to produce parts which can be used to fix and replace lab equipment in the department itself and throughout the entire Technological Park. That’s because 3D printing them internally is already significantly more affordable than purchasing them; this makes the whole institute more self-sufficient and able to carry out more advanced projects. The idea is to help entrapreneurs build a manufacturing industry almost from the ground up, but doing so with the knowledge of optimized, distributed and sustainable manufacturing of the new millennium. This is what technological leapfrogging is.