London-based 3D printing software developer Ai Build has launched Aibuild 2.0, the latest version of its cloud-based, artificial intelligence (AI) powered software.

Premiering at RAPID + TCT 2024 in Los Angeles between June 25-27, the update integrates new automation, built-in AI assistance and ISO 27001 data security certification into Ai Build’s flagship product.

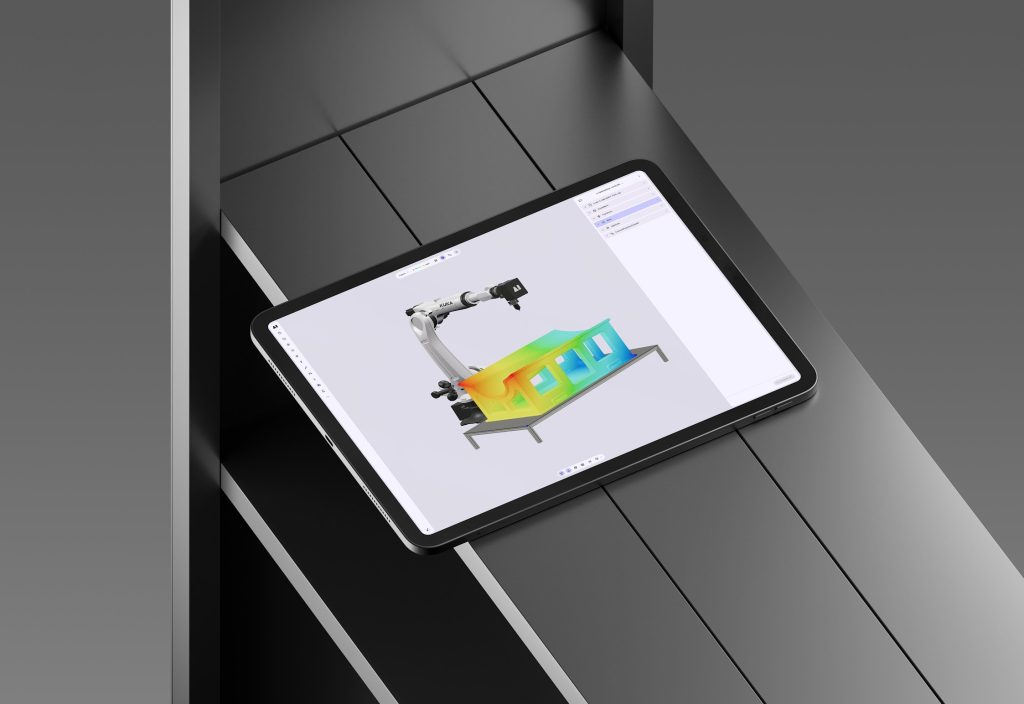

The company has also announced a new partnership with large-format 3D printer manufacturer WASP to add its CAREBRO robotic-arm 3D printing tool into Aibuild 2.0 as a digital twin. According to WASP, this integration will enable new capabilities for WASP extrusion systems, including its pellet and ceramic extruders.

Daghan Cam, Co-founder and CEO at Aibuild, believes “The future of additive manufacturing with AI-powered software is very exciting.”

“With this update, we are not only enhancing the software’s capabilities but also reinforcing our commitment to continue pushing the boundaries of additive manufacturing in collaboration with our partners and customers,” added Cam.

Introducing Aibuild 2.0

Founded in 2015, Ai Build’s software seeks to increase the accessibility and automation of industrial, large-scale additive manufacturing with AI.

The software is compatible with robotic and gantry systems and is designed to optimize the speed, quality, scalability and ease of industrial 3D printing.

The company’s offering integrates the entire additive manufacturing process into a single cloud-based platform. This includes slicing, optimization, and live 3D print control and monitoring.

Aibuild software leverages AI and machine learning (ML) to automatically generate 3D printing toolpaths for a range of additive manufacturing technologies. These include polymer extrusion, metal DED, WAAM, cold spray, concrete, and paste extrusion.

Ai Build reportedly worked closely with its key customers and partners to ensure its newly updated software meets the needs of the 3D printing industry. The company’s platform is used by manufacturing companies such as Boeing, Nikon and Ford.

Nurah Al-Haj-Mustafa, an AM engineer at Ford, stated that the Aibuild 2.0 update “takes the software to a new level” by combining technical expertise with improved user-friendliness. This, they argue, makes the new tool “accessible to everyone.”

Visitors to RAPID + TCT 2024 can see Aibuild 2.0 in action at booth #2661 in the Los Angeles Convention Center.

What’s new in Aibuild 2.0?

One key addition to Aibuild 2.0 is increased automation. Every operation on the platform is traceable and reusable. This enables users to define additive manufacturing strategies and generate ready-to-print toolpaths with a single click.

Quality control is also automated through Ai Build’s Sensor Fusion technology and AI algorithms. These analyze live process data during 3D printing, and send automatic notifications to improve production quality, enhance productivity and minimize waste.

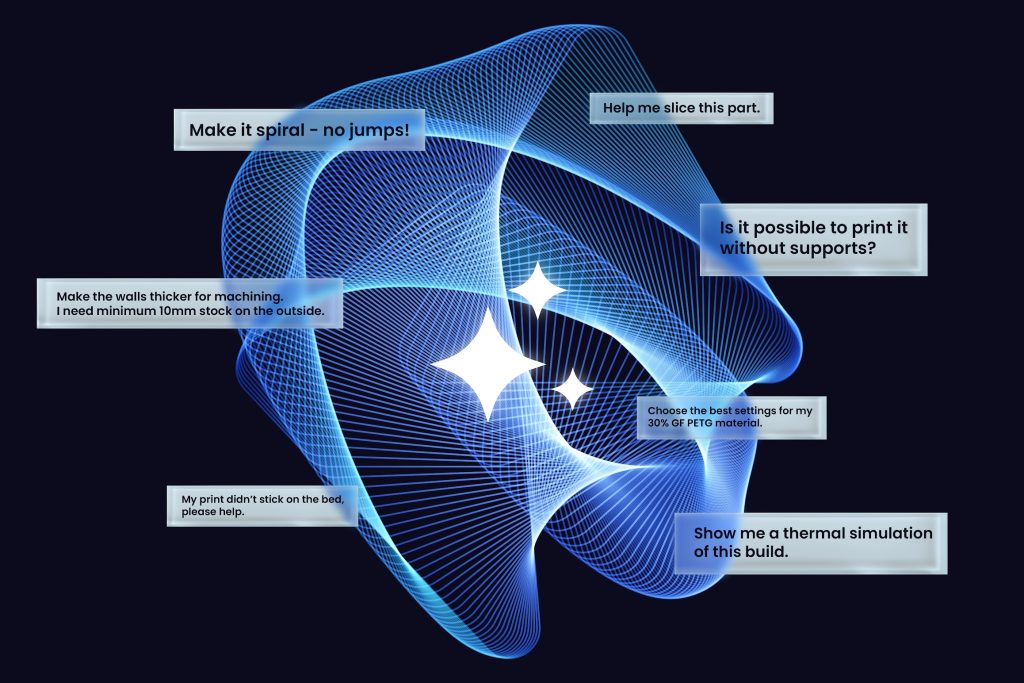

Accessibility is further enhanced by a new in-built AI assistant which autonomously recommends and performs actions to improve 3D printing outcomes.

Called Talk to AI, this feature is advertised as the world’s first AI assistant able to generate 3D printing toolpaths for unique requirements. Users can input simple text, such as “slice the part with 2mm layer height.” This is then automatically converted into instructions that optimize 3D print preparation and simulation.

Ai Build uses the same large language models that power OpenAI’s ChatGPT to power its AI assistant, which builds on the company’s previous Talk to AiSync functionality. Last year, in an interview with 3D Printing Industry, Cam explained that large language models allow the platform to “translate simple English words, plain sentences, into a stack of workflow that we create on our software.”

Aibuild 2.0 is also advertised as integrating with a growing network of additive manufacturing hardware and materials. This reportedly provides a unified digital platform for the entire 3D printing process, eliminating the need for costly and time-consuming trial and error.

The platform also features a brand-new user interface designed to be intuitive and easy to use, as well as an open platform architecture and visual programming interface. This is said to “allow the creation of advanced toolpaths without limits.”

AI Build’s new software features a secure, ISO 27001-certified cloud infrastructure. This reportedly ensures user data is safeguarded against threats such as data breaches and cyber attacks.

AI software for 3D printing

Artificial Intelligence remains a dominant buzzword in the tech world. Additive manufacturing is not immune to this AI hype, yet software developers are successfully leveraging this technology to bolster 3D printing capabilities.

Earlier this year, French software start-up Spare Parts 3D (SP3D) launched the beta program of Théia. This digital tool leverages AI to automatically create 3D models from 2D technical drawings.

Given current supply chain challenges, manufacturers are working to digitize their spare part inventories. This process can be time-consuming and costly if performed manually.

SP3D’s new offering integrates its AI-driven DigiPart software and deep learning technology to convert 2D drawings of spare parts into 3D printable models. This reportedly reduces conversion times from days to minutes.

Elsewhere, 3D printing materials producer polySpectra recently launched neThing.xyz. This software seeks to increase the accessibility of 3D CAD model creation by leveraging AI-driven generative design.

Through this free digital platform, users can prompt the AI to generate a 3D model based on their specifications and preview designs in augmented reality (AR). Users can also edit generated code, allowing them to make specific adjustments based on their preferences.

Register now for AMAA 2024 to hear insights from industry experts on additive manufacturing in aerospace, space, and defense.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows Aibuild 2.0 on an Ipad. Photo via Ai Build.