3D printing software developer AMIS has launched the first beta version of its new AMIS Pro software.

The Ghent-based company, a subsidiary of HYBRID Software, calls its new offering a functional “CAD in, print out” build preparation software for binder jetting additive manufacturing.

Compatible with Mac and Windows operating systems, the platform includes post-cad and pre-print functionality, allowing users to prepare batches of parts for 3D printing.

AMIS’ new binder jet slicing software is currently free as part of a limited public beta program and can be downloaded from the company’s official website. Customers will receive 60 days of free access to AMIS Pro v1 and can provide feedback to influence the ongoing development of the new software.

Supported by this feedback and HYBRID Software technology, the company expects to implement over 30 new features through its development roadmap.

The launch of the AMIS Pro v1 beta program is HYBRID Software’s first announcement since it launched AMIS as an internal 3D printing startup in 2023.

AMIS launches new binder jet slicing software

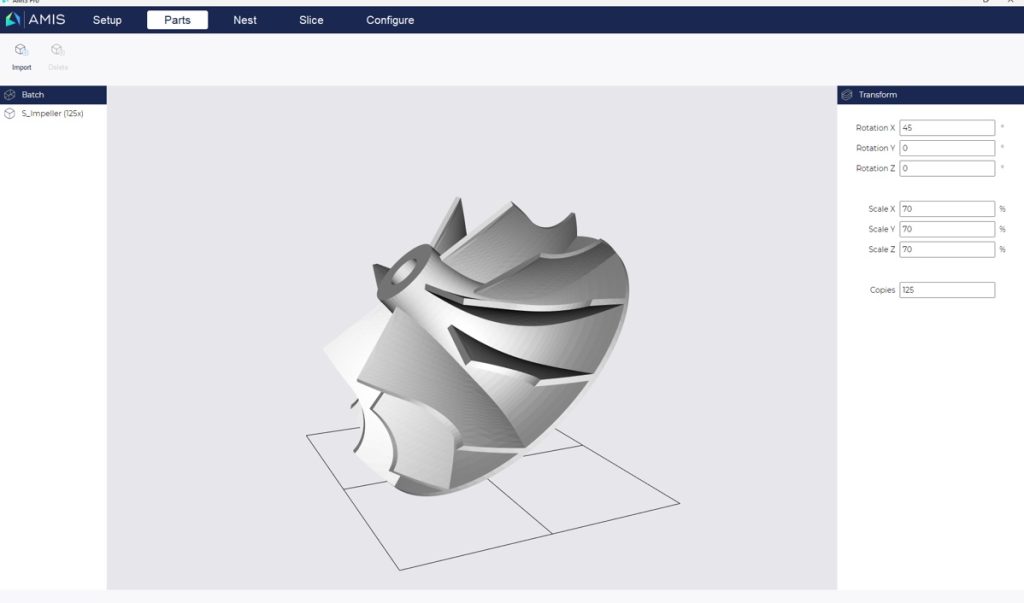

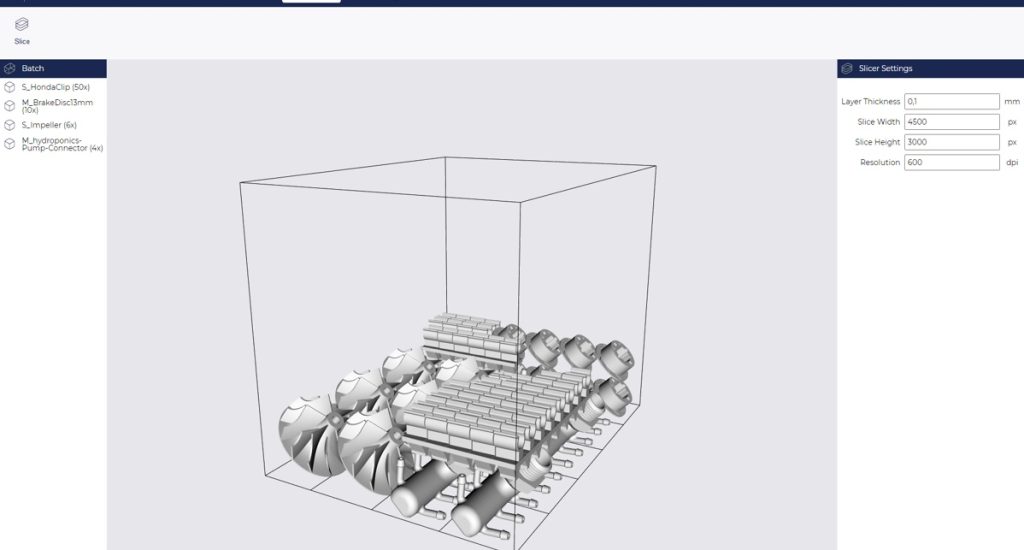

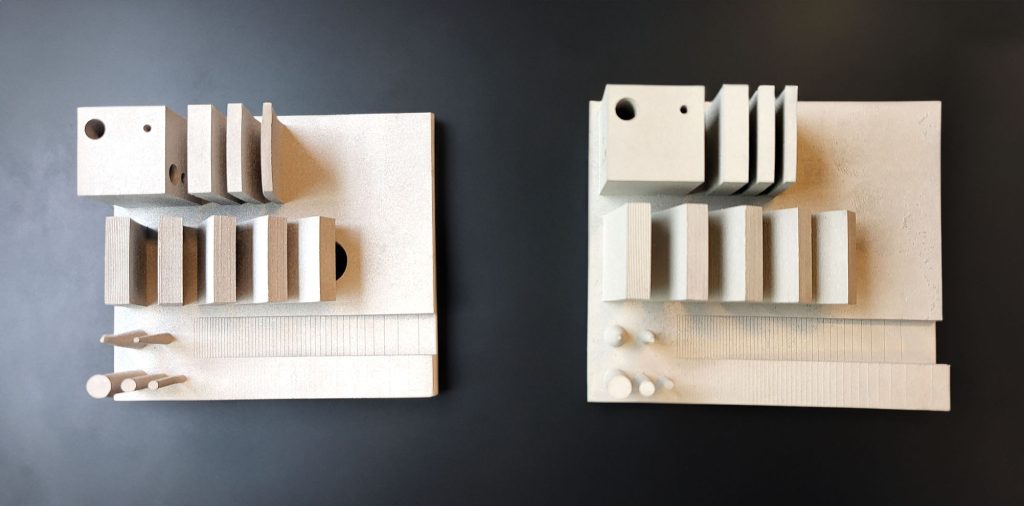

AMIS Pro v1 allows users to visualize and add multiple parts to a batch or ‘print box,’ position-orient-scale the parts, achieve voxel-based nesting, slice the batch, and send the job for 3D printing.

Additional features include the ability to save and reopen batches, specify layer thicknesses, and prepare 3D printers for production with the choice of multiple binders and materials.

According to Kris Binon, XYZ Manager at AMIS, the new software has been designed with “workflow logic” in mind.

“Which steps does the person in charge of preparing builds take? What tools does he need under his fingers at which point in time? That in itself differentiates our product, as well as the injection of decades of experience producing industrial jetting software,” explained Binon.

Metprint software, from fellow HYBRID subsidiary Meteor Inkjet, can be directly connected to AMIS Pro to optimize data transition to the 3D printheads.

Based in Cambridge, Meteor Inkjet is a top producer of printhead drive electronics, software, tools, and services for industrial inkjet 3D printing. The firm, founded in 2006, counts several of the largest 3D printer manufacturers as its clients.

The launch of AM Pro follows the news that HYBRID had developed CLOUDFLOW Maker 3D printing workflow software. Launched at Formnext 2023, the platform is designed to support industrial-scale Binder and Material Jetting. It reportedly reduces cost per part, while enhancing quality, reliability, and repeatability.

According to AMIS CEO Nick De Roeck, this offering meets the evolving needs of the 3D printing industry, with plans to leverage AI for algorithm development and collaborate with Binder and Material Jetting OEMs in the future.

New 3D printing software hit the market

New design and slicing software continue to see growing development within the 3D printing industry. Last year, 3D CAD software provider Dassault Systèmes unveiled SOLIDWORKS 2024, the latest version of its 3D design and engineering software.

This new offering is designed to meet user demand for enhanced efficiency and supports collaboration in production development.

Notable, SOLIDWORKS 2024 allows users to store their data in previous releases, enabling easier collaboration with individuals employing older versions of the software. Dassault Systèmes’ new platform also features improvements in large assembly design, parts, drawing, sheet metal, structure systems, and electrical routing.

Elsewhere, Engineering software developer nTop launched nTop 4, the latest update to its flagship 3D printing software. This offering is designed to overcome the engineering bottlenecks commonly encountered in additive manufacturing. It provides tools to design and manufacture complex parts, offering enhanced design flexibility, decreased time required to bring products to market, improved quality, and cost reduction.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows a batch of parts ready for 3D printing on AMIS Pro. Image via AMIS.