UK-based software firm MachineWorks has introduced a new demonstration featuring the development of multi-axis additive toolpaths utilizing Polygonica, the company’s polygon-mesh modeling software engine.

According to the company, the MachineWorks Software Development Kit (SDK) plays a key role in the workflow. It generates accurate polygonal representations of AM toolpaths, which are essential for analysis within MachineWorks. These representations can then be further refined using Polygonica, ultimately facilitating various downstream manufacturing tasks.

Simplifying complexities with effortless curve manipulation

Polygonica employs two primary types of curves: PTProfile and PTCurve. A PTProfile delineates planar polyline boundaries of 2D slices, while a PTCurve constitutes a 3D polycurve capable of multiple loops in 3D space, each either closed or open. Notably, PTImprintCurve variants lie on polygon mesh surfaces, ensuring seamless association and integrity during operations such as offsetting or smoothing.

The demonstration prominently features key functions like PFSolidPairCreateIntersectCurve, facilitating intersection curve generation between meshes, and PFCurveCreateOffsetCurve, which tangentially offsets imprinted curves across surfaces. Moreover, operations such as PFCurveSimplify and PFCurveConcatenate enhance curve manipulation by reducing data points and merging vertices respectively.

Additional functionalities like curve smoothing (PFCurveSmooth) and extension (PFCurveExtend) complement these capabilities, alongside curve healing functions for enhanced geometric integrity.

Examples of Polygonica’s toolpath generation

To illustrate these capabilities, MachineWorks has provided three practical examples. The first demonstrates non-planar slicing using Boolean operations and 3D curves to generate a multi-axis toolpath for additive manufacturing. By manipulating the target surface and creating intersection curves at different levels, users can efficiently generate offset toolpaths across surfaces. Visual aids depict the process with intersection curves in blue and offset toolpaths in red, culminating in simulated material addition using MachineWorks’ tools.

The second example showcases Polygonica’s application in repairing worn parts. Utilizing advanced mesh registration and alignment features, Polygonica aligns laser scan data of worn components with original CAD models. A Boolean subtraction operation defines the area needing repair, facilitating the creation of intersection curves through standard planar slicing. This approach allows for the generation of comprehensive 3-axis toolpaths using 2D hatch and infill techniques, or alternatively, by extending and intersecting surfaces to create multi-axis infill paths.

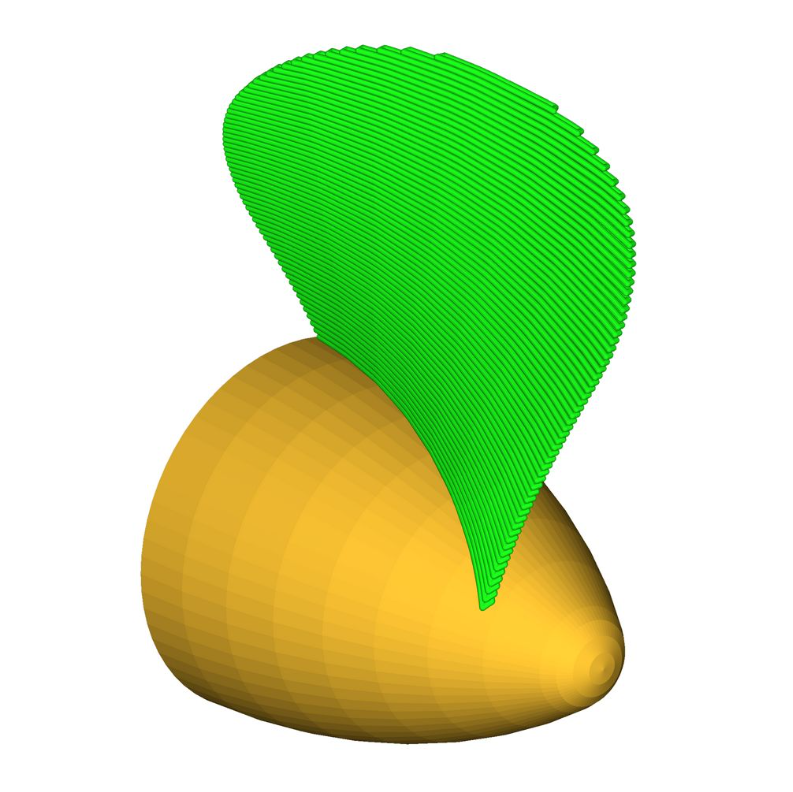

Lastly, the third example focuses on creating intersections using offset surfaces, specifically for generating propeller toolpaths. This involves offsetting engine cones and creating intersection curves with blade geometries, demonstrating the versatility of Polygonica in complex manufacturing scenarios.

Advanced manufacturing toolpath generation

Toolpath generation is crucial in 3D printing because it directly influences the quality, accuracy, and efficiency of the printed object. It ensures that the printer deposits or solidifies material in the correct places, and supports complex geometries as needed. Efficient toolpath planning can minimize print time and material waste while maximizing the structural integrity and surface finish of the final product.

Last year, Meltio introduced its Meltio Space software featuring advanced toolpath generation capabilities tailored for their wire-laser technology in metal 3D printing. It boasts user-friendly interfaces and supports various path types such as planar, non-planar, and variable extrusions, designed to integrate seamlessly with industrial robot arms including ABB, Kuka, Fanuc, and Yaskawa. The software aims to streamline the additive manufacturing workflow by offering precise kinematics simulation, collision checks, and customizable material profiles.

Months before this, Ai Build launched its novel Talk to AiSync software that allows users to refine 3D models using text prompts. This tool simplifies toolpath creation by replacing manual coding with visual programming. By integrating Ai Build’s visual toolpath programming engine with OpenAI’s GPT, it utilizes extensive manufacturing data to facilitate adjustments through straightforward text inputs. This approach enhances user experience and aims to lower barriers to entry in 3D printing, ultimately optimizing production efficiency without replacing human inputs.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows a MachineWorks simulation of the propellor additive toolpath. Image via MachineWorks.