Nominations are now open for the 3D Printing Industry Awards 2023. Who are the leaders in 3D printing? Find out on November 30th when the winners across twenty categories will be announced during a London-based live awards ceremony.

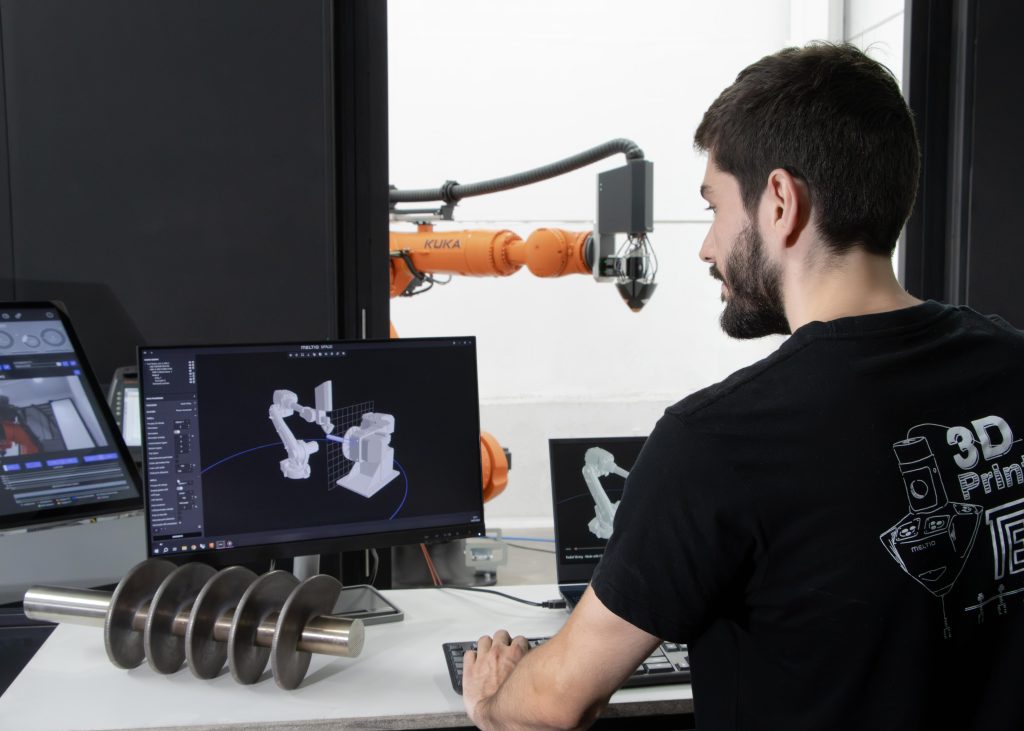

Metal 3D printing company Meltio has launched its new Meltio Space software, which it hopes will increase the adoption of the company’s wire-laser metal robot 3D printing solutions.

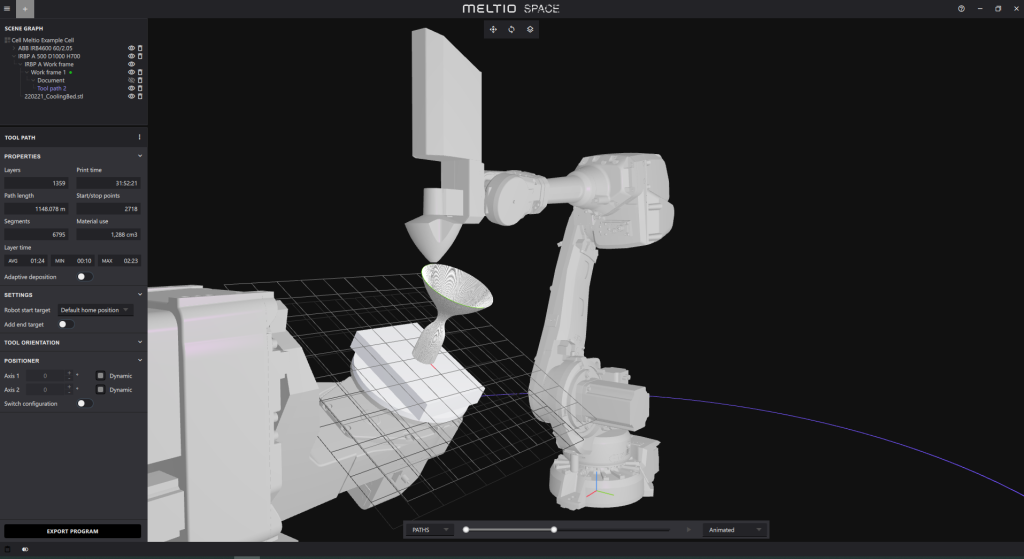

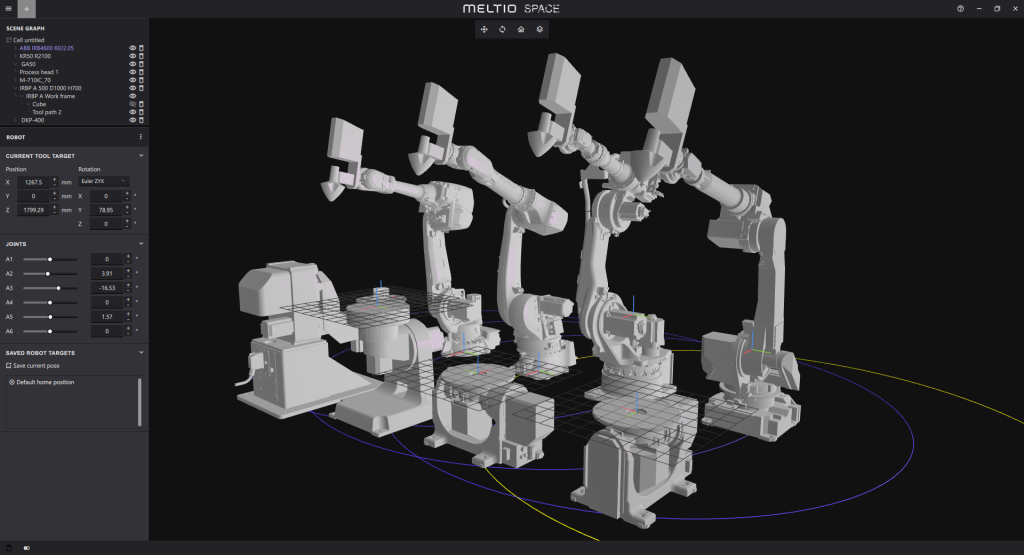

A toolpath generator software for Meltio Engine Robot Integration, Meltio Space incorporates a user-friendly interface for planar, non-planar, and variable extrusion toolpaths. 2-axis workpiece positioner interpolation, kinematics simulation, collisions check, and cell configuration are also included with the platform.

Preset and recommended materials profiles are incorporated, as well as a built in robot library and post-processors for robot arms from ABB, Kuka, Fanuc, and Yaskawa. The company claims that its new software removes complexity from the 3D printing workflow, making it accessible to users of all levels.

The software is sold as an annual subscription, the price of which is said to be the “most competitive on the market for additive manufacturing adapted to a robotic arm.” Moreover, Meltio Space is free for the first year when purchased alongside the Meltio Engine.

“Meltio Space makes it possible to design very reliable parts as quickly as possible and with a wider range of possibilities for our industrial customers. And this is thanks to a very user-friendly interface of the Meltio Engine Robot Integration,” commented Meltio Engine Product Manager Alejandro Nieto.

“The main goal of our technology is to give the most efficient tool that allows the industry the most of the applications they need to manufacture metal parts with our wire-laser technology. Meltio Space is a living platform that will provide feedback to keep improving and offer competitive software to different industrial customers of Meltio”.

Meltio’s new toolpath generator software

Last year, Meltio signed an agreement with 12 leading software companies to form the Meltio Engine Software Partners ecosystem, with these companies enjoying open compatibility with Meltio technology.

Now, thanks to Meltio Space, this wire-laser technology has been made available to a wider range of industrial customers who do not possess expertise in robotics and additive manufacturing. Indeed, the toolpath generator software has been specifically developed to accelerate the adoption of Meltio technology within the industrial additive manufacturing space.

According to Meltio, this new software streamlines the entire additive manufacturing process, offering a unified platform that enhances workflow efficiency and productivity. User experience is said to be key to the platform, which provides “seamless integration” between Meltio Space and the Meltio Engine.

Additionally, the Meltio Space robot slicer includes a virtual model of the real robot’s movements. This allows users to accurately simulate the kinematics of the robot, ensuring precise and accurate 3D printing whilst reducing programming time. The slicer also performs collision checks throughout the 3D printing process, reducing the risk of errors or damage.

By providing diverse toolpath strategies, Meltio Space enables precise movements for intricate 3D printed designs. Offering enhanced 3D print profiles for a range of materials and applications, the software optimizes Meltio Engine functionalities. Meltio Space will also be continually updated and developed, with Meltio offering a range of support, training programs, and resource platforms as part of the package.

Ultimately, Meltio claims that its Space software will help to advance additive manufacturing beyond the traditional 3-axis system, accelerating the integration of the company’s 6-axis robotic manipulator and 2-axis workpiece positioners. It is hoped that the software’s comprehensive coordination, multi-axis toolpath generation, and increased design freedom will allow users to 3D print more intricate and highly detailed parts.

Recent developments in 3D printing software

A number of companies have sought to optimize the additive manufacturing process through new software offerings. For instance, engineering software developer nTop (previously nTopology) recently launched a significant update to its flagship product: nTop 4.

Through this update, nTop’s 3D printing software offers new digital tools to design and 3D print complex parts, allowing engineers to overcome additive manufacturing bottlenecks. According to nTop, this new platform enables enhanced design flexibility, decreased time to market, cost reductions, and improved end-part quality.

“nTop 4 marks the next stage of our journey enabling engineers to deliver highly engineered AM parts for products to reach new levels of performance,” commented Bradley Rothenberg, nTop Co-founder, and CEO.

Elsewhere, 3D printer manufacturer EOS North America and its Additive Minds applied engineering team recently launched Can I 3D Print This, an online tool that seeks to make industrial 3D printing more accessible to additive manufacturing newcomers. Through this free platform, users can input information about their desired part, with the software then generating a report analyzing the part’s 3D printability.

“Our new Can I 3D Print This tool helps with initial decision-making by empowering potential users to explore and gather information about the promise of AM within their organization,” explained Dr. David Krzeminski, EOS North America senior Additive Minds consultant.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows an engineer using the new Meltio Space software. Photo via Meltio.