Nominations are now open for the 3D Printing Industry Awards 2023. Who are the leaders in 3D printing? Find out on November 30th when the winners across twenty categories will be announced during a London-based live awards ceremony.

3D printer manufacturer EOS North America and its Additive Minds applied engineering group have launched Can I 3D Print This, an online analysis tool that seeks to make metal and polymer 3D printing more accessible to those new to 3D printing.

Aimed towards organizations that are exploring industrial additive manufacturing, this new user-friendly platform allows users to input information about their desired part. The tool then generates a report on the parts 3D printability. The software is particularly focused towards laser powder bed fusion (LPBF) industrial 3D printing applications.

“For those who are new to AM, the journey often begins with the most basic question about applications or assemblies: ‘Can I 3D Print This?’” Explained Dr. David Krzeminski, EOS North America senior Additive Minds consultant. “Despite its proven advantages and widespread adoption, many companies still deem AM an emerging technology and are hesitant to augment their traditional manufacturing processes. Our new Can I 3D Print This tool helps with initial decision-making by empowering potential users to explore and gather information about the promise of AM within their organization.”

Can I 3D Print This is free to access, but will initially only be available in North America.

Answering the question: ‘Can I 3D Print This?’

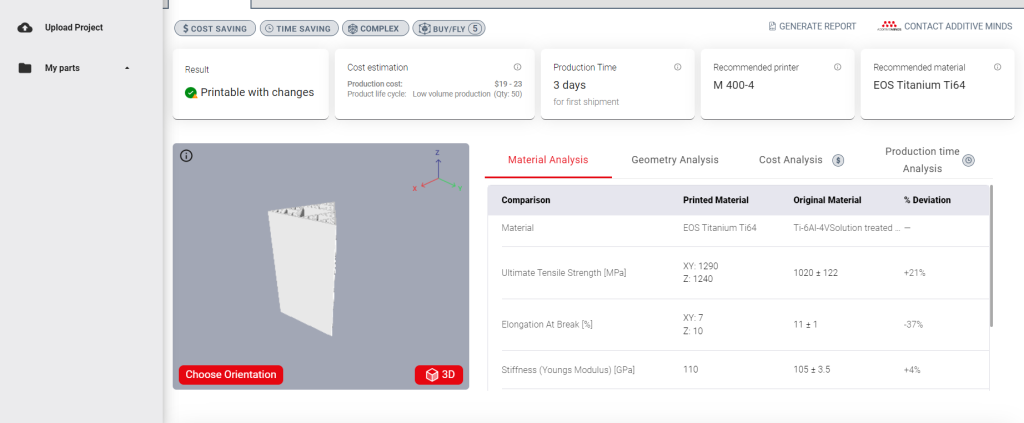

Users can input information about their current manufacturing methods and part design file into the new online tool. From this information, Can I Print This generates a comprehensive analysis including cost estimation, predicted production time, a recommended (EOS) 3D printer, and recommended material. Cost-per-part (CPP) comparisons and analysis, production timelines, application geometry analysis, and material usage when leveraging 3D printing over traditional processes are also included with the analysis. Can I 3D Print This also offers financial break-even and production time analysis comparisons against alternative manufacturing methods.

Once complete, a report on the analysis is generated and made available for the user to download. Can I 3D Print This also opens up a direct line of collaboration with the Additive Minds team. Unlike the new online tool, Additive Minds’ services are not free to access. However, the insights and data provided by Can I 3D Print This can make users better informed on whether seeking professional help is necessary.

EOS collaborated with 3D printing software developer CASTOR to develop the Can I 3D Print This platform. The online tool is currently limited to use in North America, yet EOS is exploring a global offering. Moreover, users are currently limited to the analysis of five parts. However, large batch analysis and application or assemblies can be carried out in collaboration with EOS’ Additive Minds engineering team.

3D printing part analysis and identification tools

EOS is not the first company to offer online tools to optimize part analysis and identification. Last year, Finnish additive manufacturing software company SelectAM launched a 3D printing part identification software that supports a wide range of input files. The software includes an embedded rapid slicer suited for all relevant additive manufacturing processes, whilst also enabling automated material mapping between traditional and 3D printing material.

SlectAM’s software also offers machine utilization optimization, via varied nesting strategies. These strategies can help to reduce raw materials waste. The software also enables the analysis of each assembly and single part, whilst checking the redesign potential of the product. What’s more, the software examines the part’s surface roughness and tolerances, and users can establish their own machine and material equipment profile.

Elsewhere, CASTOR also offers its own proprietary software to optimize cost control in industrial additive manufacturing. The company’s Enterprise program automatically identifies any cost-reduction opportunities in the production of spare parts and assemblies. The platform leverages Finite Elements Analysis tools to sift through a database of more than 30,000 components and recommends specific parts that would benefit from being redesigned and 3D printed.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows an example part uploaded to Can I 3D Print This.com. Image via EOS.