Nominations are now open for the 3D Printing Industry Awards 2023. Who are the leaders in 3D printing? Find out on November 30th when the winners across twenty categories will be announced during a London-based live awards ceremony.

Additive manufacturing data specialist Senvol has demonstrated a novel machine learning (ML) approach to material allowables, with the company’s ML software accurately predicting material performance.

Senvol was awarded this contract to apply its machine learning software, Senvol ML, to facilitate a path to rapid development of material property allowables for additive manufacturing. This work was carried out as part of a US Government contract W911NF-20-9-0009.

The firm’s approach is said to be more cost-effective, flexible, and time-effective than the conventional Metallic Materials Properties Development and Standardization (MMPDS) approach to material allowables development.

Senvol partnered with EWI and Pilgrim Consulting as part of the program. Private non-profit research and development (R&D) firm Battelle and Hector Sandoval, an LM Fellow at Lockheed Martin, served as technical advisers. The contract was administered by the National Center for Manufacturing Sciences (NCMS) through the AMMP Other Transaction Agreement (OTA) program.

“Material allowables development is a very expensive and time-consuming endeavor,” commented Senvol President Annie Wang. “Senvol’s program was very successful in demonstrating a new approach to additive manufacturing allowables development that leverages machine learning. We were very pleased with the results and look forward to continued work in this cutting edge area.”

Dr. William E. Frazier, retired Chief Scientist for Air Vehicle Engineer at NAVAIR and President of Pilgrim Consulting LLC, added: “I was very pleased to join Senvol’s team for this program. Senvol’s machine learning-enabled approach directly addresses a major industry challenge: the rapid and cost-effective development of additive manufacturing material property allowables.”

Optimizing material allowables development with ML

Whilst additive manufacturing enables the lightweight and time-effective production of designs, Senvol claims that these benefits are limited by the time and high cost requirements of allowables development.

This high cost is largely attributable to the fact that material allowable development requires a substantial amount of empirical data to be generated at a fixed processing point. As such, all empirical data typically needs to be generated from scratch whenever there is a major change in the process. This makes additive manufacturing processes costly and time-consuming both during initial implementation, and in the long-term when there are inevitable changes to the 3D printing procedure.

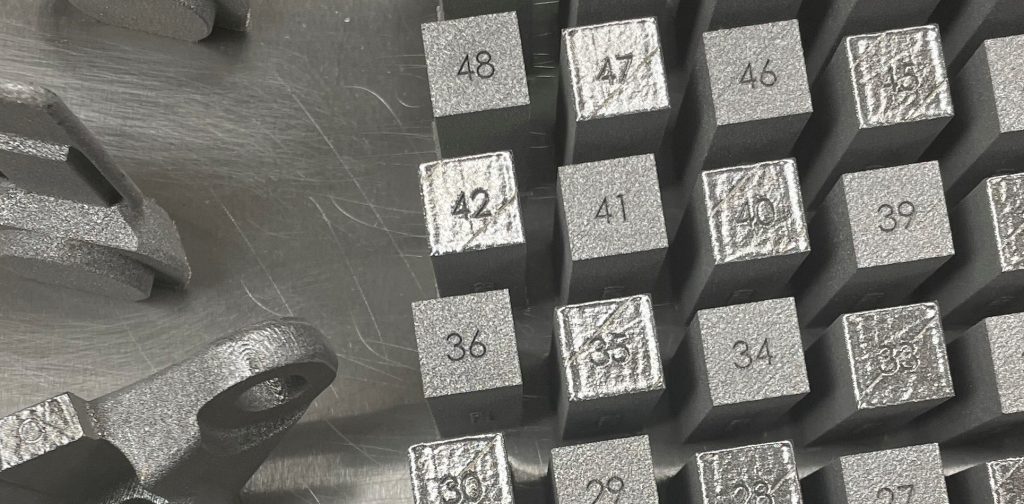

Through this program, Senvol demonstrated a novel approach to material allowables development that leverages machine learning. The program centered around a 17-4 PH Stainless Steel material, processed via a powder bed fusion 3D printer.

Senvol’s ML software, which supports the qualification of additive manufacturing processes, was leveraged in the program to develop statistical substantiated material properties comparable to material allowables. The software achieved this while simultaneously optimizing data generation requirements.

According to Senvol, this machine learning approach is flexible, and can handle changes to the AM process. Indeed, the company’s ML software can be applied to any additive manufacturing process, any 3D printer, and any material. This makes the approach ideal for long-term sustainment.

“The use of machine learning for additive manufacturing processes and material development is very mature. This has been adopted by industry and is the low-hanging fruit. The use of machine learning specifically for material allowables development, however, is still a work in progress,” explained Senvol President Zach Simkin.

“I’m pleased that we have now made two successful demonstrations of the machine learning approach to allowables – once in this program using a metal alloy and comparing to MMPDS, and once in a prior program funded by America Makes that used a polymer material and compared to CMH-17 – but more research is needed.”

“The upside is tremendous, and we look forward to continuing to partner with the Government and industry to advance work in this area,” added Simkin.

It should be noted that the project did not develop true allowables. Moreover, budget and programmatic restaurants meant that the project team had to make several simplifying decisions.

AI and ML software in additive manufacturing

A number of companies within additive manufacturing are now incorporating AI and ML capabilities into their software offerings. One such company is London-based Ai Build, which offers ML and AI driven toolpath generation and automated quality assurance through its AiSync software.

In a recent interview with 3D Printing Industry, Ai Build’s Commercial Director Luke Rogers emphasized the importance of ML capabilities in providing automated quality control. Rogers explained that, within large-format 3D printing, there is typically only a 40% success rate when 3D printing a part for the first time. According to Rogers, “using machine learning, and combining that back into the initial toolpath, you can easily get up into the 90% plus first-time print success rate.”

Elsewhere, during RAPID + TCT 2023 Montreal based high temperature 3D printer manufacturer AON3D offered a first look at its new machine learning-driven thermal optimization software.

A core technology simulation engine built specifically for Material Extrusion (MEX), this tool provides fast and accurate predictions on heat flow behavior within an object during the 3D printing process. The company claims that this software offers the potential for cost cutting, improved part reliability and consistency, performance optimization and better technical decision making.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.