Israeli electronics 3D printer manufacturer Nano Dimension is acquiring the technology and intellectual property of UK-based 3D design simulation and optimization developer Additive Flow.

This acquisition is said to mark a significant milestone in Nano Dimension’s development roadmap. Indeed, computer-aided engineering and design components are central to the company’s design-through-manufacturing product strategy.

Additive Flow’s core technology will be integrated into FLIGHT, Nano Dimensions proprietary design package suite.

“The Additive Flow team is thrilled to join Nano Dimension,” commented Alexander Pluke, Additive Flow’s Chief Executive Officer and Chief Technology Officer. “We are fortunate to have found a great partner in Nano Dimension where our innovation can be leveraged to its maximum potential. We look forward to building on our impressive track record and continuing to develop Additive Flow’s software and enhance Nano Dimension’s leading AM and AME product offerings.”

Nick Geddes, Senior Chief Technology Officer of Nano Dimension, stated that “The acquisition will add considerable firepower to the ability of our customers to leverage our leading digital manufacturing solutions.”

Additive Flow’s simulation software

Since its foundation in 2017, Additive Flow has developed high-performance and high-quality simulation software for mechanical, thermal, and thermo mechanical properties.

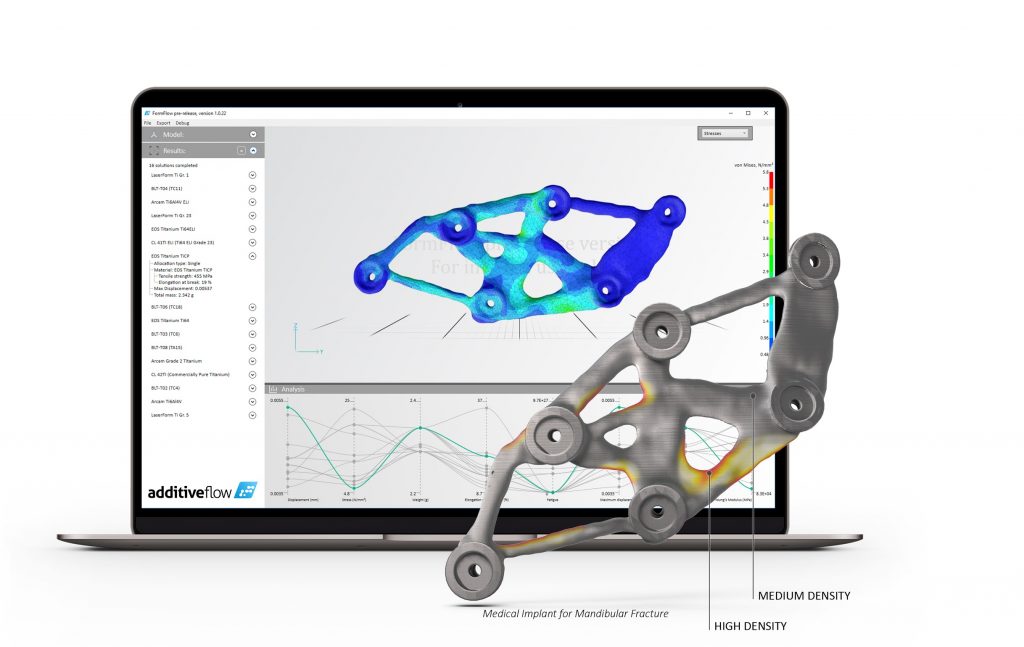

Additive Flow launched its additive manufacturing optimization software, called FormFlow, back in 2020. This software offering addresses design, production, and quality decisions, whilst optimizing cost, weight, manufacturing productivity, and manufacturing yield. The key customer base of this software incorporates the advanced optics and optoelectronics, aerospace and defense, semiconductors, advanced energy, and electronics verticals.

A multi-functional program, FormFlow offers the ability to apply multiple user-defined parameters for simultaneous geometry, process parameters, and material optimization. The software uses physics-driven algorithms, artificial intelligence (AI), and graphics processing unit (GPU) technology to process and solve complex performance issues in the design phase. Moreover, FormFlow can be tailored to work with a range of material properties, and multi-material designs.

“Our solution was born out of real engineering challenges we faced to harness the capability of advanced manufacturing,” explained Pluke. “Our platform is built from the ground up to handle all the complex data and decisions of digital engineering, so teams can focus on their key goals.”

Ultimately, Nano Dimension claims that the addition of this software will allow its customers to replicate, design, and augment additively manufactured electronics components’ prototypical layouts, in a fast and cost-effective manner.

“We have been looking at the software market for simulation and optimization offerings for some time,” added Geddes. “There are many strong solutions in the market that do certain elements of those complicated tasks, but it is Additive Flow’s product that stood out in terms of the functionality we needed for a holistic solution, especially in the context of our requirements across AME and multi-dimensional polymer, metal and ceramic AM.”

3D printing software

Process optimization and simulation software is a growing area within additive manufacturing. Indeed, recent hype surrounding artificial intelligence has seen a number of companies incorporating AI into their software offerings. This year’s 3D Printing Industry Executive Survey highlighted AI as being key to the future of 3D printing.

Earlier this month, 3D Printing Industry sat down with Daghan Cam and Luke Rogers, CEO and Commercial Director, respectively, at 3D printing software developer Ai Build. Since 2015, the London-based company has worked to develop AI driven toolpath generation and automated quality assurance software for large-format additive manufacturing.

Key to Ai Build’s mission is leveraging AI and machine learning technology to simplify the industrial additive manufacturing process, making it more accessible to more companies. “We are trying to make it super easy for anyone. Even a designer that doesn’t have much 3D printing background should be able to send their designs into machines,” explained Cam. As such, it was announced earlier this year that Ai Build had developed a process allowing users to create advanced 3D printing toolpaths using natural language prompts.

Elsewhere, engineering software developer nTop (previously nTopology) recently launched a major update to its flagship product: nTop 4. This update is said to allow engineers to overcome additive manufacturing bottlenecks, by providing new digital tools to design and manufacture complex parts. nTop claims that this new offering provides enhanced design flexibility, decreased time to market, improved part quality, and cost reduction.

“At nTop, we have always believed that design is at the core of solving the world’s hardest engineering problems. nTop 4 marks the next stage of our journey enabling engineers to deliver highly engineered AM parts for products to reach new levels of performance,” commented Bradley Rothenberg, nTop Co-founder, and CEO.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Additive Flow’s FormFlow software. Image via Additive Flow.