Artificial Intelligence is currently one of the main buzzwords in the tech world, with the additive manufacturing industry developing its fair share of AI hype over recent months. Earlier this year, the 3D Printing Industry Executive Survey highlighted automated AI 3D model generation as being key to the future of 3D printing.

Somewhat ahead of this current AI boom was 3D printing software developer Ai Build. Since 2015, the London-based company has worked to develop AI driven toolpath generation and automated quality assurance software for additive manufacturing.

3D Printing Industry recently sat down with Ai Build CEO Daghan Cam, and Commercial Director Luke Rogers, to learn more about the company’s software offerings, and how advancements in AI are impacting industrial large-format 3D printing.

Ai Build’s mission to increase AM accessibility

Ai Build was founded by Daghan Cam and company COO Michael Michail Desyllas. Coming from an architectural background, Cam and Desyllas launched the company with the aim of simplifying large-format 3D printing.

“We were really excited by the additive manufacturing technology, and we saw that as the future of making things,” explained Cam. However, Cam and Desyllas soon “started to realize that 3D printing technology is very error prone, especially when it comes to larger formats.”

Ultimately, Cam points to the “dependency on experienced machine operators to turn designs into physical parts” as stunting the development and widespread adoption of 3D printing. “We think that if we can make the technology more accessible, that’s going to unlock growth much faster.”

“We are trying to make it super easy for anyone. Even a designer that doesn’t have much 3D printing background should be able to send their designs into machines,” added Cam. “When you look at the full lifecycle, the costs quickly add up. So we are trying to make that process a lot more efficient by automating tasks. And that’s where AI really comes in.”

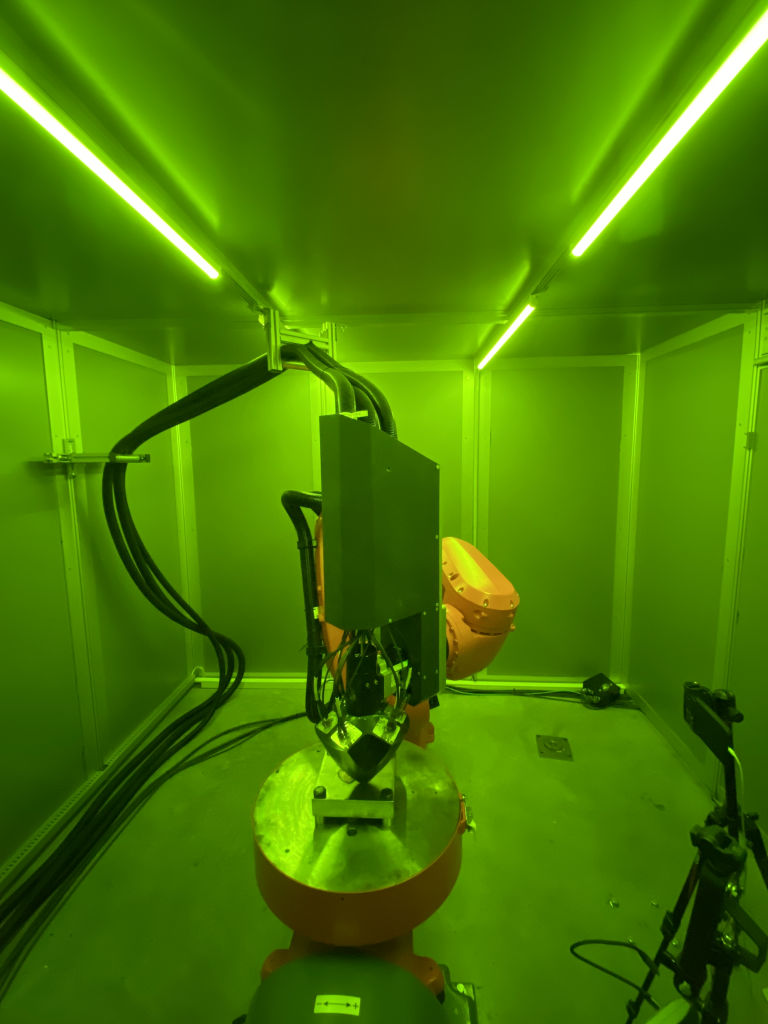

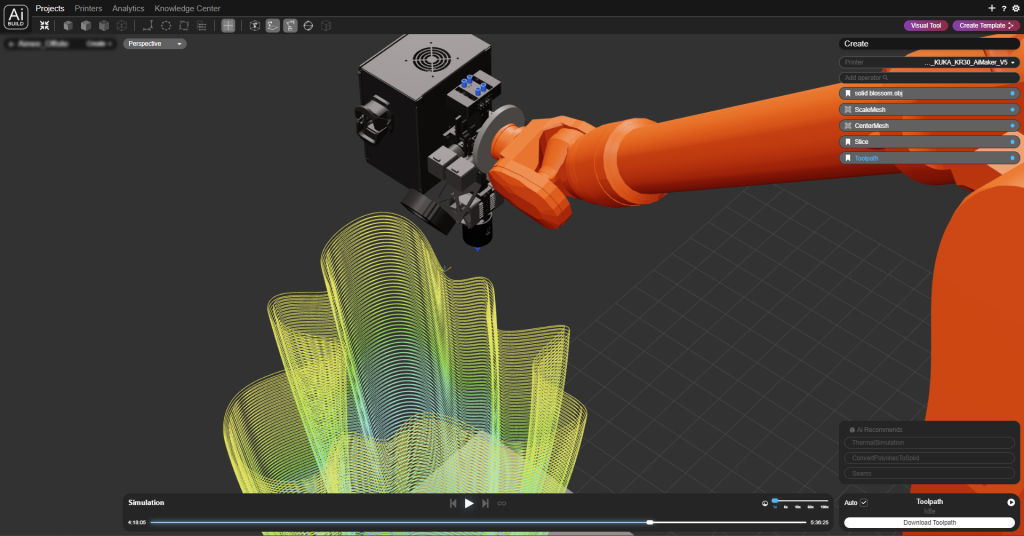

Ai Build has already partnered with a number of leading 3D printer hardware manufacturers, including Hans Weber Maschinenfabrik, Meltio, KUKA, Evo3D, CEAD, and Massive Dimension. Through these partnerships, the company incorporates a wide range of large-format 3D printers into their Ai Lab workshop. Here, the hardware is used to test, develop, verify, and integrate Ai Build’s software for a growing range of applications.

For instance, through their relationship with metal 3D printer manufacturer Meltio, Ai Build adapted their nonplanar slicing and multi-axis toolpath optimization functionality for Direct Energy Deposition (DED) metal 3D printing. “Following Meltio, we now have many different types of metal 3D printing integrated into the product. It was exciting because it suddenly unlocked a very big market opportunity for us,” commented Cam.

What are your thoughts on being based in London?

Cam was keen to point out the benefits of being based in London, highlighting the strong talent pool in the UK’s capital.

“There’s a strong engineering ecosystem, especially on the software side,” claimed Cam, who pointed to the broad range of AI software companies in the financial tech and health tech spaces. “It’s a very vibrant ecosystem, when it comes to software, AI, and digital technologies, and we are very happy to be part of that,” added Cam. “It couldn’t be the same if we were located somewhere else in the UK, but London is really the hub of software technologies and deep tech.”

However, Rogers highlighted that, whilst based in London, Ai Build is really a global organization. “We’ve got so many different people who work for us. I think, last time we counted, we had about 16 different nationalities, from about 30 Different people who work in the business. So only about a third of the company is actually present in the UK.”

Ai Build’s software

Ai Build’s key product is its AiSync software, an AI-driven toolpath optimization and quality control platform.

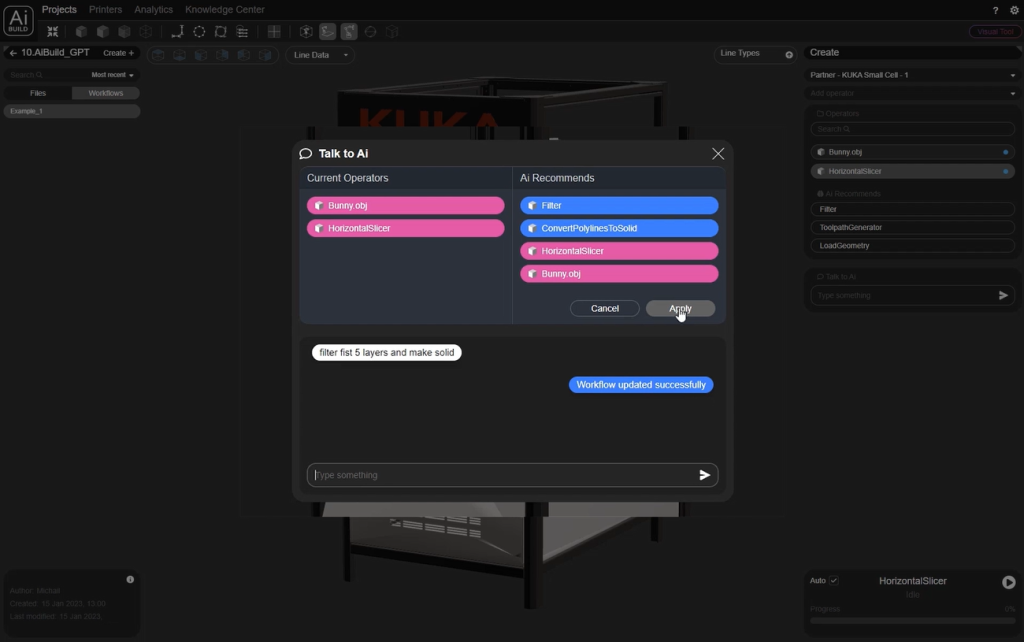

Regarding toolpath optimization, it was announced earlier this year that Ai Build had developed a process which allows users to create advanced 3D printing toolpaths using natural language prompts. This feature, called Talk to AiSync, allows users to input simple text, such as “slice the part with 2mm layer height.” This text is then translated into machine instructions to produce the desired 3D printed part.

Key to this feature is large language AI models. AiSync uses OpenAI on the back end, with GPT-4 running the software’s natural language processing. “With the addition of large language models, we are able to translate simple English words, plain sentences, into a stack of workflow that we create on our software,” explained Cam. “The goal is to make it super accessible to inexperienced users by making the user experience really smooth.”

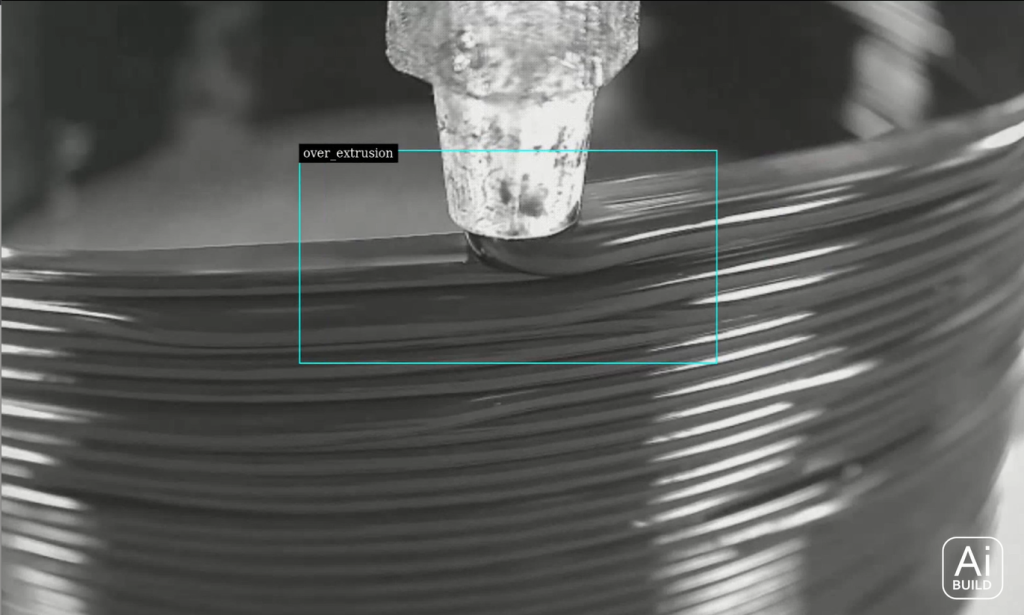

Once the toolpath has been sent to the 3D printer, AiSync provides machine-learning-driven quality control. Rogers stated that, within large-format 3D printing, there is typically only a 40% success rate when first 3D printing a part. According to Rogers, “using machine learning, and combining that back into the initial toolpath, you can easily get up into the 90% plus first-time print success rate.”

AiSync records the entire 3D printing process, automatically detecting any anomalies that were not planned during the simulation phase. Cam points to aerospace as a key vertical benefitting from this feature, especially during the production of parts that require certification and quality assurance. “They have to do lots and lots of testing after production. We are minimizing that need for non-destructive testing and different types of qualifications.”

Beyond aerospace, Cam highlighted automotive, energy, marine, and construction as the key vertices this software is aimed towards. “I would say maybe 80 or 90% of our customers are falling into one of these five categories,” claimed Cam. Whilst Cam could not disclose too many names, global engineering solutions firm Weir Group and aerospace manufacturer Boeing were pinpointed as key customers

employing AiSync software.

AiSync cloud connectivity

AiSync is also cloud-based, something which is said to differentiate AI Build from the competition. “As far as I’m aware, we are the only company that has a cloud platform that’s driven by the use of data and collaboration, and the use of AI,” claims Cam. Rogers echoed this sentiment, adding that “There’s no one doing exactly what we’re doing.”

“We are enabling the free flow of information, and that leads to much faster innovation and shorter product life cycles,” according to Cam. “It’s all about accessibility and convenience for the users. You don’t need to install anything, so you can be on your mobile phone or iPad and next to the machine.”

In addition to remote 3D print monitoring and control capabilities, this cloud connectivity also allows data to be transferred and tests conducted “between geographies.” Cam pointed to one example whereby toolpaths were created in the company’s London-based Ai Lab. These instructions were then sent to a 3D printer in Germany, where the parts were 3D printed without any additional human input.

Key advantages of using AI within additive manufacturing

What are the key benefits of incorporating AI technology into additive manufacturing? Cam pointed to scaling, with AI being “crucial” to achieving full automation, “which we think is needed to scale the technology.”

“If the process is not automated, it’s error prone because it’s dependent on the quality of your additive engineers knowledge, and the knowledge transfer is extremely difficult,” commented Cam. “Our goal is to fully automate the process, and AI becomes really critical towards the end of that last mile of automation.”

Whilst Ai Sync does not currently offer full automation, but is rather a collaborative process between user and software, Cam asserted that “where we are going is definitely higher and higher levels of automation.”

“As we get there, the process is becoming much more efficient. Less errors, less cost. Many new applications get unlocked as the cost is getting lower by automating the process.”

So what are the time and cost savings offered by AI? According to Cam, “It’s very application specific.”

When it comes to tooling applications, the biggest benefit of AI is cutting the prototyping phase. Cam claims that, currently, engineers are having to make a best guess on the slicing software and toolpath generation, physically 3D printing the part to view the results.

“So it usually takes two to three attempts until they get it right the first time. It’s usually a few weeks before the production actually starts from the design phase. And in the worst case, they might need to go back to design and iterate on the design as well,” stated Cam. Therefore, AI modeling and simulation makes a significant impact on this stage of development, “eliminating the prototyping phase before the actual production begins.”

With regards to high-volume production, AI is said to mainly benefit quality assurance. “It’s really important for customers to have trust in the technology,” claims Cam. This is where AiSync comes in. “We are taking that quality assurance and putting it inside the process […] As you print the parts you have a live report and the post-print reports that give full confidence to the customer.”

The future of AI and additive manufacturing

Looking forward, Cam sees a bright future for AI and 3D printing, viewing “AI as a very strong companion to engineers and designers.” Key to this relationship is said to be communication.

“The role of AI moving forward is going to be around making the communication between the computers, the systems and the humans a lot more fluid. So fluid that it will feel like there is no computer, you’re just talking to a colleague and the machine understands what you mean,” commented Cam.

Rogers echoed this sentiment, stating that “in the future, you won’t need technical competence to be able to run machines.” The long-term goal of AiSync is to further simplify the additive manufacturing process, “to make it accessible, to reduce that barrier of entry, to allow the parts to be produced at a higher quality, faster and more accurately than any human mind can do.”

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Ai Build CEO Daghan Cam at Ai Build’s Ai Lab. Photo by 3D Printing Industry.