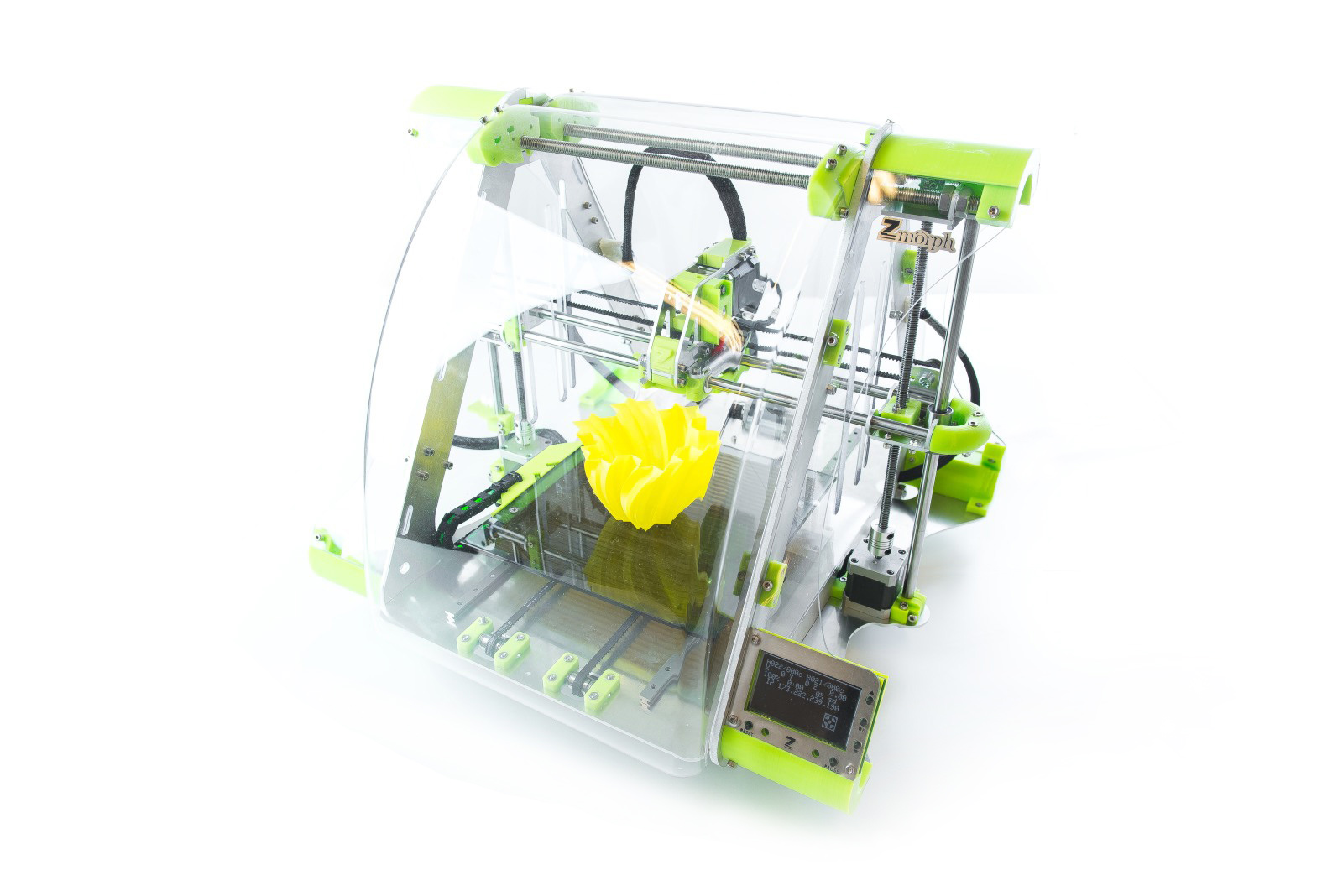

The ZMorph 2.0 S is the latest iteration of the Polish company’s signature 3D printer. It has been completely redesigned with an entirely metal frame, faster print speeds and updated firmware. The 2.0 S Personal Fabricator has the capability to change toolheads so a single 3D printer can do the job of eleven different machines.

The all-in-one or multi-use 3D printer is becoming the newest trend in the 3D printing industry, and it’s one that has long been overdue. There are so many uses for the technology involved in 3D printing that it is unrealistic to expect consumers to buy a different machine for each type of use when most of the technology is identical.

The new ZMorph 2.0 S has a brand new sturdy metal frame that brings more stability and precision to the printing process. The 2.0 S can reportedly reach printing speeds as fast as 120mm/s and the new Z-axis can produce models with a resolution down to 0.001mm. The updated firmware was also redesigned to be more intuitive, user-friendly and simplify the 3D printing process.

Here is a video of the new ZMorph 2.0 S in action:

The printer has a build envelope of 250mm x 235mm x 165mm (9.8inch x 9.2inch x 6.5inch) and is compatible with both 1.75 and 3mm filaments. It can print with most filament and 3D printing materials available including PLA, ABS, laywood, nylon, polycarbonate, BandLay, ceramics, and even foods like chocolate and cake decorations.

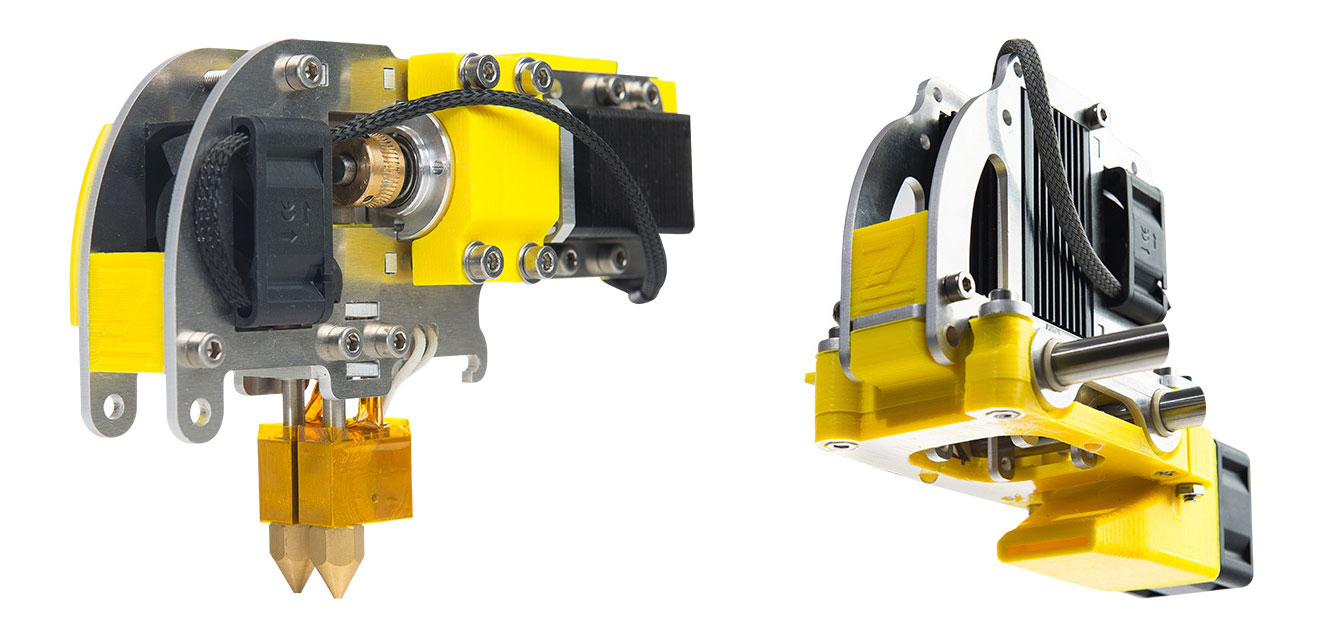

Of course the real star of the ZMorph 2.0 S is the various interchangeable toolheads that are already available. The printer comes standard with a single head extruder and can easily be swapped out for a dual head extruder, ceramics extruder and of course the chocolate and food extruder. There is also a fitting to mount a dremel so you can turn it into a milling and engraving toolhead. Some of the alternate types of toolheads include a laser cutter, a camera trigger, a time lapse rail, a touch probe and a 5-axis universal toolhead attachment.

The basic 3D printer costs $1,868 with the dual head extruder costing an additional $440. The laser toolhead seems to be the priciest add-on at $551. While the low end tools include the ceramics toolhead costing $124 and the chocolate and cake toolhead costing $128. Each machine is manufactured to order and will be fully assembled, tested and running before it’s shipped to you.